Wet litter in poultry farming creates a humid, unhygienic environment that promotes disease and footpad dermatitis, while dry litter helps maintain bird health by reducing ammonia levels and moisture buildup. Effective floor management prioritizes dry litter through proper ventilation, regular cleaning, and controlled watering systems to prevent litter dampness. Choosing dry litter methods enhances bird welfare, improves growth performance, and lowers mortality rates in poultry farming.

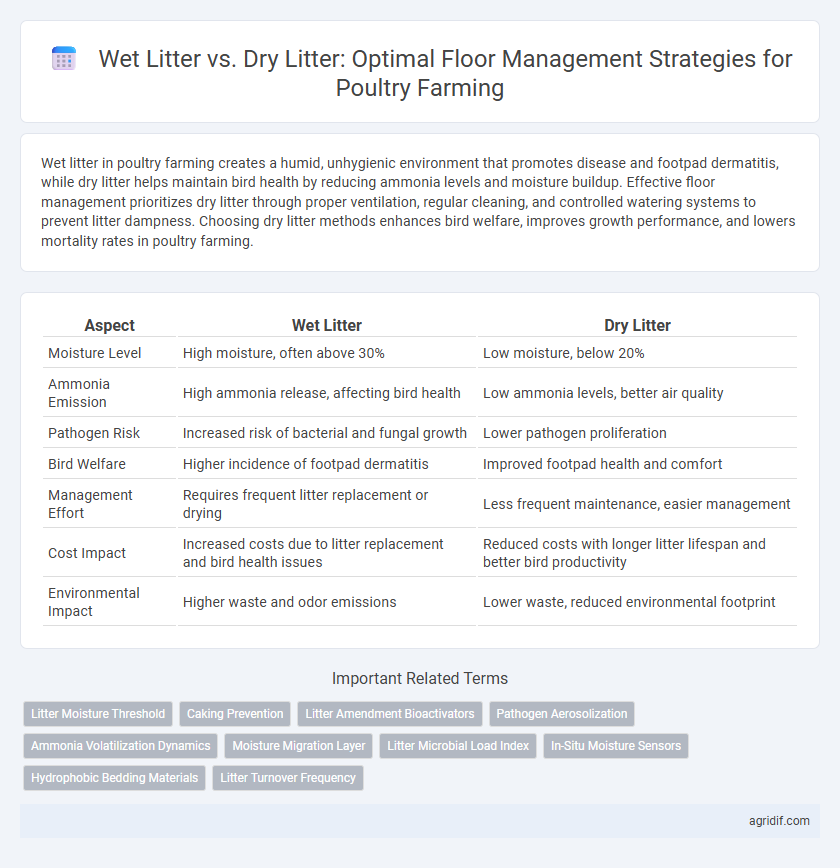

Table of Comparison

| Aspect | Wet Litter | Dry Litter |

|---|---|---|

| Moisture Level | High moisture, often above 30% | Low moisture, below 20% |

| Ammonia Emission | High ammonia release, affecting bird health | Low ammonia levels, better air quality |

| Pathogen Risk | Increased risk of bacterial and fungal growth | Lower pathogen proliferation |

| Bird Welfare | Higher incidence of footpad dermatitis | Improved footpad health and comfort |

| Management Effort | Requires frequent litter replacement or drying | Less frequent maintenance, easier management |

| Cost Impact | Increased costs due to litter replacement and bird health issues | Reduced costs with longer litter lifespan and better bird productivity |

| Environmental Impact | Higher waste and odor emissions | Lower waste, reduced environmental footprint |

Understanding Wet and Dry Litter in Poultry Farming

Wet litter in poultry farming leads to increased ammonia levels, higher risk of footpad dermatitis, and poor bird health, while dry litter promotes better air quality and healthier living conditions. Effective floor management requires monitoring moisture content, ensuring adequate ventilation, and using absorbent materials to maintain dry litter. Understanding the balance between wet and dry litter directly impacts flock welfare, growth performance, and overall farm profitability.

Causes of Wet Litter in Poultry Houses

Wet litter in poultry houses primarily results from excessive moisture due to water spillage, high humidity, inadequate ventilation, and poor drainage systems. Overwatering and leaks in drinkers or water lines significantly contribute to wet litter problems. Managing environmental factors such as temperature and airflow is crucial to prevent litter dampness and maintain poultry health and productivity.

Advantages of Maintaining Dry Litter

Maintaining dry litter in poultry farming enhances bird health by minimizing the risk of bacterial growth and ammonia build-up, which reduces respiratory issues and footpad dermatitis. Dry litter improves flock comfort and mobility, leading to better weight gain and feed efficiency during the production cycle. Proper moisture control in dry litter also facilitates easier manure handling and reduces the spread of pathogens in the poultry house environment.

Challenges Associated with Wet Litter

Wet litter in poultry farming presents significant challenges such as increased ammonia levels, which can cause respiratory issues and stress in birds, leading to higher susceptibility to diseases like coccidiosis and footpad dermatitis. Wet litter also promotes bacterial growth and parasite infestations, reducing overall flock health and productivity. Managing moisture through proper drainage, ventilation, and litter material selection is critical to prevent these detrimental effects and maintain optimal floor conditions.

Impact on Bird Health: Wet vs Dry Litter

Wet litter in poultry houses increases the risk of bacterial growth, leading to higher incidences of footpad dermatitis, respiratory infections, and ammonia toxicity among birds. Dry litter maintains optimal moisture levels, promoting better air quality and reducing pathogen proliferation, which significantly enhances bird health and welfare. Consistently monitoring litter moisture and employing effective ventilation systems are critical for preventing health issues associated with wet litter conditions.

Influence on Ammonia Emissions and Air Quality

Wet litter in poultry farming significantly increases ammonia emissions due to enhanced microbial activity, which deteriorates air quality and adversely affects bird respiratory health. Dry litter, maintained through effective ventilation and moisture control, reduces ammonia volatilization, thereby creating a healthier environment for poultry and workers. Optimizing litter management practices is crucial for minimizing ammonia-related environmental and health risks.

Best Practices for Preventing Wet Litter

Maintaining dry litter in poultry houses is critical for preventing ammonia buildup, disease outbreaks, and footpad dermatitis in flocks. Best practices for preventing wet litter include effective ventilation to reduce humidity, using absorbent bedding materials like wood shavings or rice hulls, and promptly managing water leaks or spills. Regular litter turning and maintaining appropriate stocking densities also enhance moisture control and promote flock health.

Litter Material Selection and Management Strategies

Selecting appropriate litter material in poultry farming significantly impacts floor management by affecting moisture control, bird health, and overall productivity. Materials like wood shavings, rice hulls, and sand provide varying absorption rates, with dry litter promoting better air quality and reducing pathogens compared to wet litter. Effective management strategies include regular litter turning, moisture monitoring, and ensuring proper ventilation to maintain dry conditions and prevent bacterial growth.

Economic Implications of Litter Moisture Levels

Excessive moisture in poultry litter increases ammonia production, leading to respiratory issues and higher veterinary costs, which reduce overall profitability. Dry litter minimizes pathogen growth, decreasing mortality rates and improving feed conversion efficiency, thus enhancing economic returns. Effective moisture control in litter management directly influences operational costs and flock performance, making it a critical factor in sustainable poultry farming economics.

Innovations and Technologies for Litter Control

Innovations in poultry farming have introduced advanced moisture sensors and automated ventilation systems to maintain dry litter, significantly reducing ammonia levels and improving bird health. High-efficiency litter conditioners and drying agents, combined with real-time environmental monitoring, optimize floor moisture management, preventing wet litter-related diseases. These technologies enhance production efficiency by promoting better air quality and prolonging litter usability, crucial for sustainable poultry floor management.

Related Important Terms

Litter Moisture Threshold

Maintaining litter moisture below 25% in poultry houses is critical to prevent wet litter, which fosters ammonia buildup and increases the risk of footpad dermatitis in broilers. Optimal floor management involves regular monitoring and ventilation control to sustain dry litter conditions, ensuring bird health and performance.

Caking Prevention

Proper floor management in poultry farming emphasizes maintaining dry litter to prevent caking, which inhibits moisture buildup and bacterial growth that can lead to footpad dermatitis and poor bird health. Using absorbent materials like wood shavings and ensuring adequate ventilation are critical strategies to keep litter dry and free from caking, promoting optimal bird comfort and hygiene.

Litter Amendment Bioactivators

Litter amendment bioactivators play a crucial role in maintaining dry litter by accelerating the decomposition of poultry waste and reducing moisture accumulation in poultry houses. Effective application of these bioactivators improves air quality, minimizes ammonia emissions, and enhances bird health compared to wet litter conditions that promote pathogenic growth and poor floor management.

Pathogen Aerosolization

Wet litter in poultry houses significantly increases the risk of pathogen aerosolization, facilitating the airborne spread of harmful bacteria and viruses such as Salmonella and Campylobacter. Maintaining dry litter reduces microbial growth and minimizes respiratory exposure of both birds and workers to infectious agents, thereby improving overall flock health and biosecurity.

Ammonia Volatilization Dynamics

Wet litter conditions in poultry houses significantly increase ammonia volatilization dynamics due to higher moisture content accelerating microbial decomposition of uric acid, leading to elevated ammonia gas emissions. Maintaining dry litter reduces ammonia formation by limiting microbial activity, improving air quality, bird health, and overall production efficiency in poultry farming.

Moisture Migration Layer

Moisture Migration Layer plays a critical role in poultry floor management by influencing the balance between wet and dry litter, directly impacting bird health and ammonia levels. Maintaining a well-managed moisture migration layer prevents excessive dampness, reducing pathogen growth and improving overall litter quality essential for optimal poultry production.

Litter Microbial Load Index

Wet litter in poultry farming significantly increases the Litter Microbial Load Index, promoting higher levels of pathogenic bacteria such as Escherichia coli and Clostridium perfringens, which adversely affect bird health. Maintaining dry litter reduces microbial proliferation, lower ammonia emissions, and supports improved footpad health and overall flock performance.

In-Situ Moisture Sensors

In poultry farming, in-situ moisture sensors provide real-time monitoring of litter moisture levels, enabling precise management between wet litter, which can increase ammonia and pathogen risks, and dry litter that promotes bird health and performance. These sensors optimize floor management by alerting farmers to critical moisture thresholds, reducing the incidence of footpad dermatitis and improving overall flock welfare.

Hydrophobic Bedding Materials

Hydrophobic bedding materials like rice hulls and wood shavings reduce moisture retention in poultry litter, promoting drier floor conditions and minimizing bacterial growth and ammonia emissions. Maintaining dry litter through these materials enhances bird health, reduces footpad dermatitis incidence, and improves overall poultry welfare and productivity.

Litter Turnover Frequency

Wet litter in poultry farming increases the risk of ammonia buildup and disease, necessitating more frequent litter turnover to maintain bird health and comfort. Dry litter promotes better air quality and reduces pathogen growth, allowing for longer intervals between cleanings and more efficient floor management.

Wet Litter vs Dry Litter for Floor Management Infographic

agridif.com

agridif.com