Section control in precision agriculture significantly reduces pesticide waste by applying chemicals only where needed, avoiding overlap and untreated gaps. Without section control, pesticide application is less efficient, leading to excessive chemical use and increased environmental impact. Implementing section control enhances application accuracy, lowers costs, and promotes sustainable farming practices.

Table of Comparison

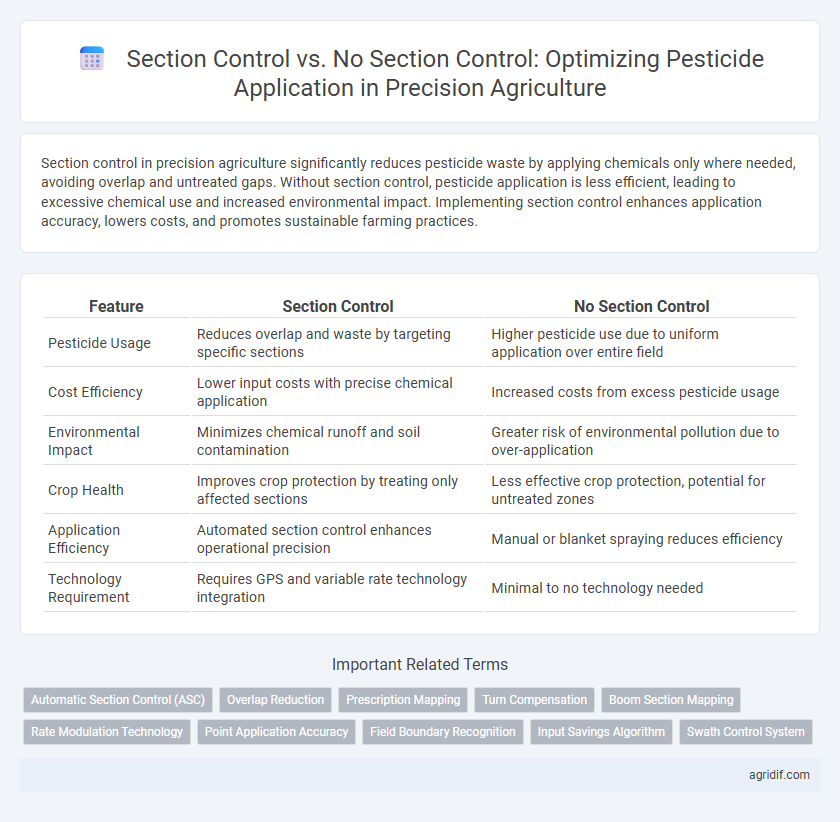

| Feature | Section Control | No Section Control |

|---|---|---|

| Pesticide Usage | Reduces overlap and waste by targeting specific sections | Higher pesticide use due to uniform application over entire field |

| Cost Efficiency | Lower input costs with precise chemical application | Increased costs from excess pesticide usage |

| Environmental Impact | Minimizes chemical runoff and soil contamination | Greater risk of environmental pollution due to over-application |

| Crop Health | Improves crop protection by treating only affected sections | Less effective crop protection, potential for untreated zones |

| Application Efficiency | Automated section control enhances operational precision | Manual or blanket spraying reduces efficiency |

| Technology Requirement | Requires GPS and variable rate technology integration | Minimal to no technology needed |

Introduction to Section Control in Precision Agriculture

Section Control in Precision Agriculture enhances pesticide application by enabling automatic on/off control of sprayer sections, which minimizes overlap and reduces chemical waste. This technology employs GPS and variable rate application maps to target specific field areas, increasing efficiency and lowering environmental impact. Without Section Control, pesticide distribution is uniform but often results in over-application, higher costs, and greater ecological risk.

Understanding No Section Control Systems

No Section Control systems apply pesticides continuously across an entire field without adjusting for specific crop or soil variability, leading to potential over-application and increased chemical costs. Lack of targeted control reduces efficiency and can harm the environment by increasing pesticide runoff and resistance. Understanding these limitations highlights the importance of adopting Section Control technologies for precision application and sustainability.

Key Differences Between Section Control and No Section Control

Section control in pesticide application utilizes GPS and sensor technology to activate and deactivate spray nozzles precisely, reducing overlap and minimizing chemical waste. No section control applies pesticides uniformly across the entire field, leading to increased input costs and higher environmental impact due to over-application in some areas. The key differences lie in efficiency, cost savings, and environmental sustainability, with section control offering targeted application that enhances crop protection and reduces operator error.

Impact on Pesticide Usage Efficiency

Section control technology in precision agriculture significantly enhances pesticide usage efficiency by precisely targeting treated areas, reducing overlap and minimizing waste. Without section control, pesticide application often results in excessive use, increased environmental runoff, and higher input costs due to uniform spraying over entire fields regardless of variability. Employing GPS-guided section control can lead to pesticide savings of up to 20-30%, promoting sustainable farming practices and optimizing resource management.

Cost Comparison: Section Control vs No Section Control

Section control technology significantly reduces pesticide costs by targeting specific field zones, minimizing over-application and waste compared to no section control methods. Fields treated without section control often experience overlapping spray areas, increasing chemical use and expenses. Cost savings from section control can reach up to 20-30%, optimizing input efficiency and lowering environmental impact.

Environmental Implications of Each System

Section control in pesticide application reduces chemical overlap by precisely targeting treated areas, minimizing excessive pesticide use and lowering environmental contamination risks. Without section control, uniform spraying leads to over-application in some zones, increasing pesticide runoff and harm to surrounding ecosystems. Implementing section control enhances sustainable agriculture by reducing pollution and promoting better soil and water health.

Crop Yield and Quality Impacts

Section control technology in pesticide application significantly enhances crop yield by minimizing over-application and reducing chemical drift, leading to more uniform crop protection and healthier plants. Without section control, excessive pesticide use can cause plant stress and damage, resulting in lower yield and compromised crop quality. Utilizing section control ensures precise targeting of pesticide application, improving both the quantity and quality of agricultural produce through optimized chemical use.

Technological Requirements for Section Control

Section control systems for pesticide application require GPS-enabled machinery with real-time positioning accuracy within 2-5 centimeters to ensure precise overlap reduction and avoid gaps. Integration of variable-rate technology (VRT) controllers allows automated on/off switching of individual boom sections based on pre-mapped field boundaries or sensor data. Reliable wireless communication protocols and robust software platforms are essential for seamless data exchange between the guidance system, sensors, and spray controllers, optimizing input usage and minimizing environmental impact.

User Experience and Operational Challenges

Section control technology in pesticide application enhances user experience by minimizing overlap and reducing chemical waste, leading to cost savings and environmental benefits. Operators without section control face challenges such as inconsistent application rates and higher risk of over- or under-treatment, which can impact crop health and yield. The precise on/off functionality of section control systems simplifies decision-making and decreases operator fatigue during field operations.

Future Trends in Pesticide Application Technologies

Section control technology significantly reduces pesticide overlap and waste by automatically turning spray nozzles on and off based on GPS mapping, enhancing both environmental sustainability and cost efficiency. Future trends in pesticide application are moving towards integrating AI-driven analytics and real-time sensor data to optimize variable rate applications, further improving accuracy and minimizing chemical use. Emerging technologies such as drone-based precision spraying and machine learning algorithms also promise to revolutionize precision agriculture by enabling more adaptive, site-specific pest control solutions.

Related Important Terms

Automatic Section Control (ASC)

Automatic Section Control (ASC) in precision agriculture optimizes pesticide application by activating sprayer sections only over targeted areas, reducing overlap and minimizing chemical waste. This technology enhances field efficiency, lowers input costs, and decreases environmental impact compared to no section control, which often leads to excessive pesticide use and uneven coverage.

Overlap Reduction

Section control technology in pesticide application significantly reduces overlap by automatically turning off sprayer sections when passing over previously treated areas, minimizing chemical waste and environmental impact. In contrast, no section control results in frequent overlap, increasing pesticide usage and risk of crop damage due to uneven application.

Prescription Mapping

Section control in pesticide application uses Prescription Mapping to optimize chemical use by applying pesticides only where needed, reducing overlap and minimizing environmental impact. Without section control, uniform spraying leads to over-application in some areas and under-application in others, increasing costs and potential crop damage.

Turn Compensation

Section control in pesticide application minimizes overlap and reduces chemical waste by automatically turning off spray sections when machinery enters already treated zones, enhancing turn compensation efficiency. Without section control, pesticide overlap during turns leads to excessive chemical use and environmental runoff, decreasing application precision and increasing operational costs.

Boom Section Mapping

Section control in pesticide application using boom section mapping reduces overlap and gaps, optimizing chemical usage and minimizing environmental impact. Without section control, uniform spraying leads to excessive pesticide use, increased costs, and higher risk of crop damage.

Rate Modulation Technology

Section control enhances pesticide application efficiency by precisely activating and deactivating spray sections to eliminate overlap and reduce chemical waste. Rate modulation technology further optimizes this process by adjusting the application rate in real-time based on field variability, improving environmental sustainability and crop health.

Point Application Accuracy

Section control in pesticide application significantly enhances point application accuracy by minimizing overlap and gaps, ensuring precise targeting of treated areas. In contrast, no section control often leads to inconsistent pesticide distribution, increasing waste and potential environmental impact.

Field Boundary Recognition

Section control in pesticide application enhances field boundary recognition by automatically disabling spray nozzles at the edges, reducing chemical overlap and environmental contamination. Without section control, operators risk excessive pesticide use along boundaries, leading to increased costs and potential harm to adjacent ecosystems.

Input Savings Algorithm

Section control technology in pesticide application uses real-time GPS data and field mapping algorithms to activate sprayer sections only over target areas, significantly reducing input waste by preventing overlap and skips. This savings algorithm optimizes pesticide usage, cutting costs and minimizing environmental impact compared to no section control methods that treat fields uniformly without accounting for variability.

Swath Control System

Swath Control System in precision agriculture optimizes pesticide application by automatically turning sections of the sprayer on and off, minimizing overlap and reducing chemical waste. Fields using Section Control demonstrate increased efficiency and environmental sustainability compared to No Section Control, where uniform spraying without overlap prevention leads to excessive pesticide use and higher operational costs.

Section Control vs No Section Control for pesticide application Infographic

agridif.com

agridif.com