Automatic Section Control enhances spraying efficiency by reducing overlap and chemical waste, ensuring precise application tailored to field conditions. Manual Boom Control relies on operator judgment and can lead to inconsistent coverage and increased input costs. Adopting Automatic Section Control improves accuracy, lowers environmental impact, and optimizes resource use in precision agriculture.

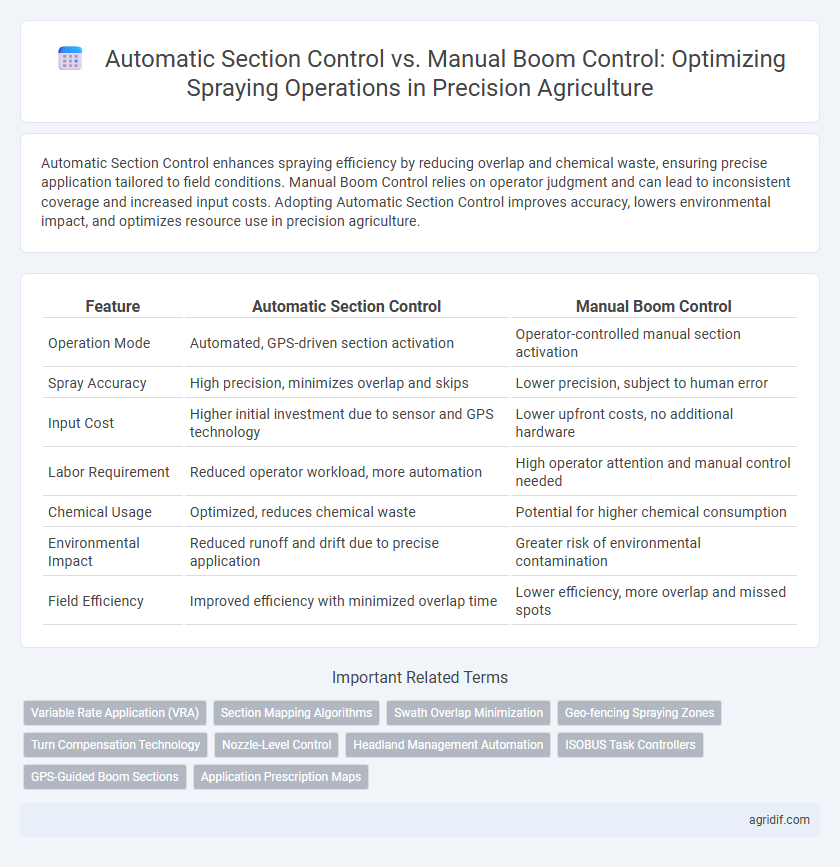

Table of Comparison

| Feature | Automatic Section Control | Manual Boom Control |

|---|---|---|

| Operation Mode | Automated, GPS-driven section activation | Operator-controlled manual section activation |

| Spray Accuracy | High precision, minimizes overlap and skips | Lower precision, subject to human error |

| Input Cost | Higher initial investment due to sensor and GPS technology | Lower upfront costs, no additional hardware |

| Labor Requirement | Reduced operator workload, more automation | High operator attention and manual control needed |

| Chemical Usage | Optimized, reduces chemical waste | Potential for higher chemical consumption |

| Environmental Impact | Reduced runoff and drift due to precise application | Greater risk of environmental contamination |

| Field Efficiency | Improved efficiency with minimized overlap time | Lower efficiency, more overlap and missed spots |

Introduction to Precision Agriculture Spraying Technologies

Automatic Section Control enhances spraying accuracy by using GPS data to activate and deactivate boom sections, reducing overlap and chemical waste. Manual Boom Control relies on operator skill, increasing the risk of inconsistent application and environmental impact. Precision Agriculture Spraying Technologies prioritize efficiency, cost savings, and sustainable crop management through automation and sensor integration.

Understanding Automatic Section Control

Automatic Section Control in precision agriculture significantly enhances spraying efficiency by reducing overlap and minimizing chemical waste. This technology uses GPS and sensors to detect previously treated areas, enabling real-time adjustment of spray nozzles, which improves field coverage accuracy compared to manual boom control. Implementing Automatic Section Control leads to cost savings, environmental protection, and optimized crop health through precise input application.

Overview of Manual Boom Control Systems

Manual boom control systems require the operator to adjust the spray boom sections manually based on visual cues or pre-set maps, increasing the risk of overlap or gaps in coverage. These systems lack real-time feedback and rely heavily on the operator's attention and experience, potentially leading to inefficient chemical usage and uneven pesticide distribution. Despite being cost-effective, manual control often results in increased input costs and environmental impact compared to automatic section control technologies.

Key Differences Between Automatic and Manual Control

Automatic section control in spraying operations uses GPS and sensors to precisely manage spray patterns, reducing overlap and chemical waste, while manual boom control relies on operator judgment, increasing the risk of inconsistencies and inefficiencies. Automatic systems enhance accuracy by adapting spray sections in real-time based on field boundaries and crop variability, whereas manual control depends heavily on operator experience and attention. The integration of automatic section control leads to improved resource efficiency, cost savings, and environmental protection compared to the variable precision of manual boom adjustments.

Efficiency in Chemical Application

Automatic Section Control significantly improves chemical application efficiency by precisely activating spray nozzles only over targeted areas, reducing overlap and minimizing chemical waste. Manual Boom Control often results in inconsistent coverage and higher chemical use due to human error and the inability to adjust spray sections dynamically. Implementing Automatic Section Control enhances cost savings and environmental sustainability through optimized chemical distribution in precision agriculture.

Impact on Crop Health and Yield

Automatic Section Control improves crop health and yield by precisely targeting spray applications, minimizing over- and under-application, and reducing chemical overlap. Manual Boom Control often results in inconsistent coverage, leading to areas of stress or pest vulnerability that can reduce overall crop performance. Precision in automatic systems enhances resource efficiency and promotes uniform crop development, directly contributing to higher yields and healthier plants.

Cost-Benefit Analysis: Automation vs Manual

Automatic Section Control significantly reduces overlap and chemical waste, leading to cost savings of up to 20% on inputs compared to manual boom control. While initial investment in automation technology can be high, the increased efficiency and reduced labor costs provide a strong return on investment within two to three seasons. Manual boom control incurs higher variable costs due to human error and inefficient application, negatively impacting overall profitability in spraying operations.

Reducing Overspray and Environmental Impact

Automatic Section Control technology in precision agriculture significantly reduces overspray by using GPS and sensor data to precisely activate and deactivate sprayer sections, minimizing chemical waste and environmental contamination. Manual Boom Control relies on operator skill and timing, often resulting in inconsistent application and higher chances of chemical overlap or gaps. Implementing automatic control systems enhances spray accuracy, lowers input costs, and promotes sustainable farming practices by protecting surrounding ecosystems from excess pesticide exposure.

User Experience and Operational Challenges

Automatic Section Control enhances user experience by reducing overlap and minimizing chemical waste, leading to more efficient spraying operations compared to Manual Boom Control. Operators face fewer operational challenges such as fatigue and inconsistent application rates, as the automated system adjusts spray sections in real time based on GPS data. Manual Boom Control demands constant vigilance and manual adjustments, increasing the likelihood of errors and operator strain during long hours in the field.

Future Trends in Spraying Technology Integration

Automatic Section Control systems in spraying operations enhance precision by using GPS and sensor data to independently manage boom sections, significantly reducing overlap and chemical waste compared to Manual Boom Control, which relies on operator judgment. Future trends indicate deeper integration of AI-driven analytics and real-time field mapping to optimize spray patterns, improving efficiency and sustainability in precision agriculture. Emerging technologies focus on seamless connectivity with farm management systems, enabling autonomous decision-making and adaptive spraying based on crop variability and environmental conditions.

Related Important Terms

Variable Rate Application (VRA)

Automatic Section Control enhances spraying accuracy by using GPS and sensor data to adjust boom sections in real-time, reducing overlap and chemical waste during Variable Rate Application. Manual Boom Control relies on operator input, leading to less precise application and increased risk of over- or under-spraying in variable field conditions.

Section Mapping Algorithms

Automatic Section Control leverages advanced section mapping algorithms that dynamically adjust spray coverage based on real-time GPS and field boundary data, significantly reducing overlap and chemical waste compared to Manual Boom Control. These algorithms integrate variable rate technology and precise geospatial mapping to optimize application accuracy, improving crop health and operational efficiency in precision agriculture.

Swath Overlap Minimization

Automatic Section Control (ASC) significantly reduces swath overlap in spraying operations by using GPS data to precisely activate and deactivate boom sections, resulting in optimized chemical application and reduced input costs. In contrast, Manual Boom Control relies on operator skill and visual estimation, often leading to inconsistent coverage and increased overlap, which can waste resources and increase environmental impact.

Geo-fencing Spraying Zones

Automatic Section Control uses GPS-based geo-fencing to precisely activate and deactivate spray nozzles, reducing overlap and minimizing chemical waste within defined spraying zones. Manual Boom Control lacks real-time boundary detection, leading to potential over-application and inconsistent coverage compared to the accuracy provided by geo-fenced automatic systems.

Turn Compensation Technology

Automatic Section Control with Turn Compensation Technology enhances spraying precision by automatically adjusting spray sections based on the boom's position during turns, minimizing overlap and chemical waste. Manual Boom Control lacks this real-time adjustment, increasing the risk of over-application and inefficient input usage in complex field geometries.

Nozzle-Level Control

Automatic Section Control enhances spraying efficiency by adjusting nozzle activation based on GPS data, minimizing overlap and reducing chemical waste compared to Manual Boom Control, which relies on operator judgment and often results in inconsistent application. Nozzle-level control in Automatic Section Control systems further refines accuracy by independently managing each nozzle, optimizing chemical use and improving crop health through precise, site-specific treatment.

Headland Management Automation

Automatic Section Control (ASC) significantly enhances headland management in spraying operations by precisely activating and deactivating boom sections based on GPS-guided field boundaries, reducing overlap and chemical waste compared to Manual Boom Control. This automation improves application accuracy during turns and headland passes, optimizing input use and minimizing environmental impact.

ISOBUS Task Controllers

ISOBUS Task Controllers enable automatic section control by precisely managing spray boom sections based on GPS data, reducing overlaps and minimizing chemical waste compared to manual boom control. This technology enhances spraying accuracy, operational efficiency, and environmental sustainability in precision agriculture.

GPS-Guided Boom Sections

GPS-guided boom sections in automatic section control systems optimize spraying operations by minimizing overlap and reducing chemical waste, enhancing precision and cost-efficiency compared to manual boom control. These systems leverage real-time GPS data to activate or deactivate spray nozzles accurately, improving application accuracy and environmental sustainability in precision agriculture.

Application Prescription Maps

Automatic Section Control leverages Application Prescription Maps to optimize spraying by dynamically adjusting boom sections based on precise field variability, reducing overlap and chemical waste. Manual Boom Control relies on operator judgment without real-time map integration, often leading to inconsistent application and increased input costs.

Automatic Section Control vs Manual Boom Control for spraying operations Infographic

agridif.com

agridif.com