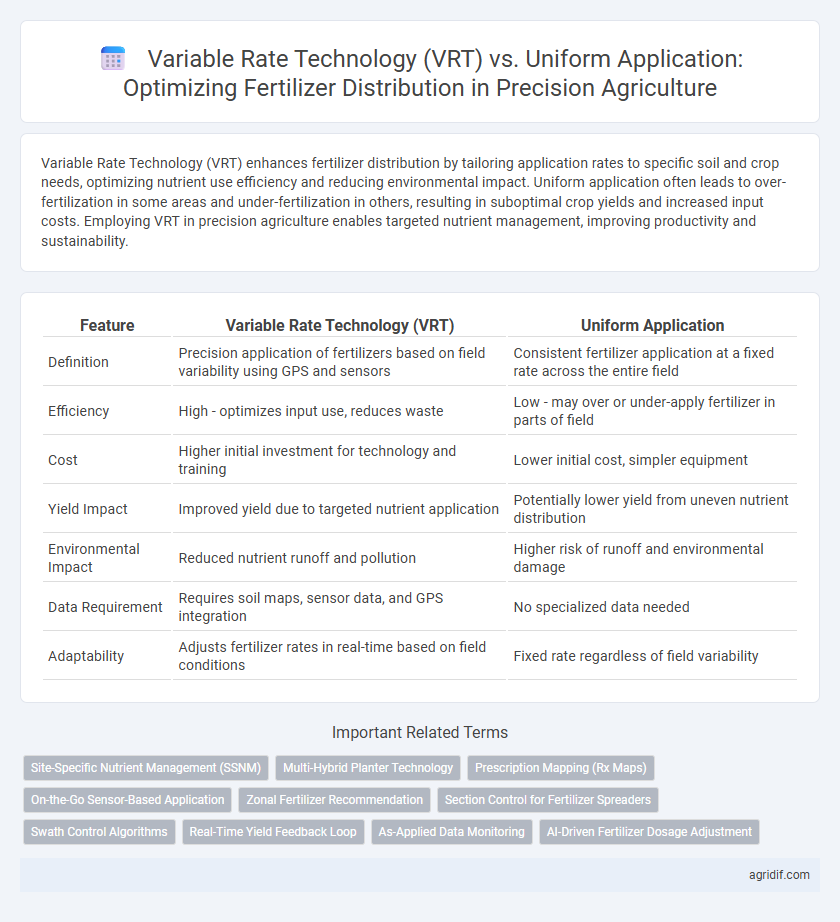

Variable Rate Technology (VRT) enhances fertilizer distribution by tailoring application rates to specific soil and crop needs, optimizing nutrient use efficiency and reducing environmental impact. Uniform application often leads to over-fertilization in some areas and under-fertilization in others, resulting in suboptimal crop yields and increased input costs. Employing VRT in precision agriculture enables targeted nutrient management, improving productivity and sustainability.

Table of Comparison

| Feature | Variable Rate Technology (VRT) | Uniform Application |

|---|---|---|

| Definition | Precision application of fertilizers based on field variability using GPS and sensors | Consistent fertilizer application at a fixed rate across the entire field |

| Efficiency | High - optimizes input use, reduces waste | Low - may over or under-apply fertilizer in parts of field |

| Cost | Higher initial investment for technology and training | Lower initial cost, simpler equipment |

| Yield Impact | Improved yield due to targeted nutrient application | Potentially lower yield from uneven nutrient distribution |

| Environmental Impact | Reduced nutrient runoff and pollution | Higher risk of runoff and environmental damage |

| Data Requirement | Requires soil maps, sensor data, and GPS integration | No specialized data needed |

| Adaptability | Adjusts fertilizer rates in real-time based on field conditions | Fixed rate regardless of field variability |

Introduction to Precision Agriculture and Fertilizer Distribution

Variable Rate Technology (VRT) in precision agriculture enables site-specific fertilizer application, optimizing nutrient distribution according to soil variability and crop needs, which enhances efficiency and reduces waste compared to uniform application methods. Studies show VRT can increase crop yield by up to 15% and decrease fertilizer use by 20%, directly benefiting environmental sustainability and farm profitability. Integrating GPS, soil sensors, and advanced mapping, VRT represents a significant advancement over traditional uniform fertilizer distribution, aligning input use precisely with spatial variability.

Understanding Variable Rate Technology (VRT)

Variable Rate Technology (VRT) enables precise fertilizer application by adjusting the amount of input based on real-time data such as soil nutrient levels, crop health, and field variability, optimizing resource use and enhancing crop yields. Unlike uniform application methods that apply a constant fertilizer rate across the entire field, VRT minimizes waste and environmental impact by targeting specific areas with customized input rates. This technology integrates GPS mapping, sensors, and prescription algorithms to improve nutrient efficiency and sustainable farming practices.

The Principles of Uniform Fertilizer Application

Uniform fertilizer application distributes nutrients evenly across a field, aiming for consistent crop growth by maintaining a constant application rate regardless of soil variability. This method relies on the principle that uniform nutrient availability supports uniform plant development, minimizing areas of nutrient deficiency or excess. However, it may lead to inefficient fertilizer use in heterogeneous fields, unlike Variable Rate Technology (VRT) which adjusts inputs based on spatial variability.

Comparing Efficiency: VRT vs Uniform Application

Variable Rate Technology (VRT) enhances fertilizer efficiency by tailoring nutrient application based on real-time soil and crop data, reducing waste and increasing yield potential. Uniform application distributes the same fertilizer amount across fields, often leading to over- or under-fertilization in different zones, which decreases cost-effectiveness and environmental sustainability. Studies show VRT can improve nutrient use efficiency by up to 20%, significantly lowering input costs and minimizing runoff compared to uniform methods.

Impact on Crop Yield and Quality

Variable Rate Technology (VRT) optimizes fertilizer distribution by adjusting input quantities based on real-time soil and crop conditions, significantly enhancing crop yield and quality compared to uniform application methods. Studies show VRT can increase nutrient use efficiency by up to 30%, leading to improved plant health and reduced environmental impact. Uniform fertilizer application often results in nutrient wastage and uneven crop growth, negatively affecting overall yield and produce quality.

Environmental Sustainability and Nutrient Management

Variable Rate Technology (VRT) enhances environmental sustainability by precisely tailoring fertilizer distribution based on real-time soil nutrient data, reducing excess application and minimizing runoff pollution. Unlike uniform application, which applies a constant fertilizer rate regardless of field variability, VRT optimizes nutrient use efficiency, promoting healthier soil ecosystems and lowering greenhouse gas emissions. Implementing VRT supports sustainable nutrient management by enabling targeted interventions that conserve resources and improve crop yield quality.

Cost-Benefit Analysis of VRT and Uniform Application

Variable Rate Technology (VRT) for fertilizer distribution optimizes input use by applying nutrients precisely based on soil variability, often leading to reduced fertilizer costs and enhanced crop yields compared to uniform application methods. Studies indicate that VRT can decrease fertilizer usage by 15-30%, resulting in significant cost savings and increased environmental sustainability, while uniform application tends to overuse inputs, raising expenses without corresponding yield benefits. The cost-benefit analysis reveals that despite higher initial investment in VRT equipment and technology, long-term savings and yield improvements typically offset these costs, making VRT economically advantageous for large-scale precision agriculture operations.

Technological Requirements and Implementation

Variable Rate Technology (VRT) for fertilizer distribution requires advanced components such as GPS guidance systems, prescription mapping software, and sensor-based application equipment to deliver site-specific nutrient management. Uniform application relies on conventional spreaders with fixed rate settings, demanding less technological infrastructure and simpler calibration. Implementing VRT involves integrating precision hardware with farm management platforms and ongoing data analysis, whereas uniform application emphasizes operational simplicity and lower initial investment.

Case Studies: Real-World Outcomes

Variable Rate Technology (VRT) in fertilizer distribution improves nutrient use efficiency by tailoring applications to specific field variability, resulting in yield increases of up to 15% and cost savings demonstrated in case studies across corn and wheat crops. Uniform application often leads to over- or under-fertilization, causing nutrient runoff or deficiencies that reduce productivity and environmental sustainability. Field trials in the Midwest U.S. and Europe reveal VRT's capacity to optimize input usage while maintaining soil health and minimizing ecological impact compared to uniform methods.

Future Trends in Fertilizer Application Technology

Variable Rate Technology (VRT) in fertilizer application leverages GPS and sensor data to optimize nutrient delivery, enhancing crop yield and reducing waste compared to uniform application methods. Future trends indicate increased integration of AI and machine learning to predict precise fertilizer needs dynamically, further improving efficiency and environmental sustainability. Advancements in drone and robotic systems are expected to complement VRT, enabling real-time adjustments and site-specific nutrient management at unprecedented scales.

Related Important Terms

Site-Specific Nutrient Management (SSNM)

Variable Rate Technology (VRT) enhances Site-Specific Nutrient Management (SSNM) by adjusting fertilizer application based on soil variability and crop requirements, improving nutrient use efficiency and minimizing environmental impact. Uniform application ignores field heterogeneity, often leading to nutrient overuse in certain areas and deficiencies in others, resulting in suboptimal crop yields and increased costs.

Multi-Hybrid Planter Technology

Variable Rate Technology (VRT) in fertilizer distribution leverages real-time data to optimize nutrient application by soil variability, enhancing crop yield and resource efficiency compared to uniform application methods. Multi-Hybrid Planter Technology complements VRT by allowing simultaneous planting of different hybrid seeds tailored to specific field zones, maximizing genetic potential and environmental adaptation.

Prescription Mapping (Rx Maps)

Variable Rate Technology (VRT) leverages Prescription Mapping (Rx Maps) to tailor fertilizer application based on precise field data, optimizing nutrient distribution and enhancing crop yield compared to uniform application methods. Rx Maps integrate soil variability, crop needs, and GPS data, enabling site-specific management that reduces input waste and environmental impact.

On-the-Go Sensor-Based Application

Variable Rate Technology (VRT) with On-the-Go Sensor-Based Application enhances fertilizer efficiency by precisely adjusting nutrient levels in real-time based on soil and crop variability, significantly reducing waste and environmental impact compared to Uniform Application. This dynamic approach increases crop yield potential and optimizes input costs by delivering customized fertilizer doses tailored to specific field conditions.

Zonal Fertilizer Recommendation

Variable Rate Technology (VRT) enhances fertilizer efficiency by applying nutrients precisely based on soil variability and crop needs within defined zones, contrasting with uniform application that distributes fertilizers evenly regardless of field heterogeneity. Zonal fertilizer recommendation within VRT leverages spatial data and sensors to optimize nutrient use, improving crop yield, reducing waste, and minimizing environmental impact.

Section Control for Fertilizer Spreaders

Section control in Variable Rate Technology (VRT) enables precise fertilizer application by automatically turning spreader sections on or off based on GPS data and field maps, reducing overlap and minimizing waste. Unlike uniform application, VRT's section control enhances nutrient efficiency and lowers environmental impact by adapting fertilizer distribution to the specific needs of each field zone.

Swath Control Algorithms

Swath control algorithms in Variable Rate Technology (VRT) optimize fertilizer distribution by precisely adjusting application rates based on real-time field data, minimizing overlap and gaps compared to uniform application methods. This targeted approach enhances nutrient efficiency, reduces waste, and improves crop yield consistency across diverse soil zones.

Real-Time Yield Feedback Loop

Variable Rate Technology (VRT) uses sensors and GPS data to adjust fertilizer application in real-time based on yield feedback, enhancing nutrient use efficiency and crop performance. Uniform application applies consistent fertilizer rates across fields, often leading to over- or under-fertilization, reducing yield optimization and increasing environmental impact.

As-Applied Data Monitoring

Variable Rate Technology (VRT) enhances fertilizer distribution by using GPS and sensor data to adjust application rates in real-time, optimizing nutrient use efficiency and minimizing environmental impact. Uniform application lacks site-specific adjustments, resulting in over- or under-fertilization, whereas VRT's as-applied data monitoring provides precise records for improved crop management and yield predictions.

AI-Driven Fertilizer Dosage Adjustment

AI-driven Variable Rate Technology (VRT) optimizes fertilizer distribution by adjusting dosage in real-time based on soil nutrient variability, crop health, and environmental data, enhancing nutrient use efficiency and reducing waste. Uniform application applies a consistent fertilizer rate across fields, often leading to suboptimal crop performance and increased environmental impact due to over- or under-fertilization.

Variable Rate Technology (VRT) vs Uniform Application for Fertilizer Distribution Infographic

agridif.com

agridif.com