Autonomous tractors enhance field operations by integrating GPS technology and AI, enabling precise navigation and optimized planting or harvesting without human intervention. Conventional tractors rely on manual operation, which can lead to inconsistent performance and increased labor costs. The adoption of autonomous tractors results in improved efficiency, reduced fuel consumption, and minimized soil compaction compared to traditional methods.

Table of Comparison

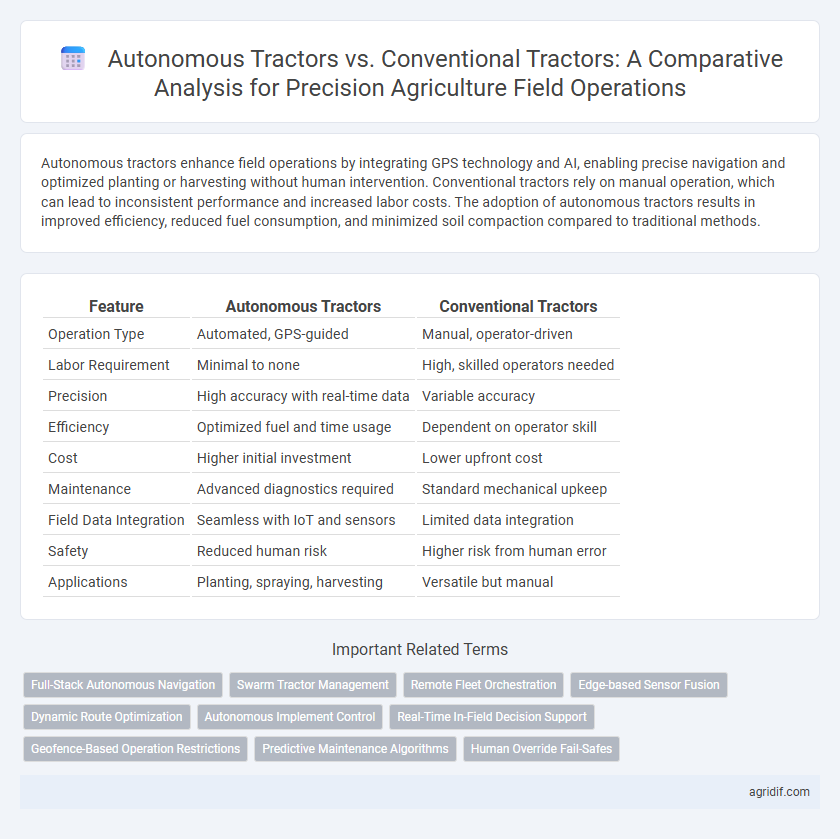

| Feature | Autonomous Tractors | Conventional Tractors |

|---|---|---|

| Operation Type | Automated, GPS-guided | Manual, operator-driven |

| Labor Requirement | Minimal to none | High, skilled operators needed |

| Precision | High accuracy with real-time data | Variable accuracy |

| Efficiency | Optimized fuel and time usage | Dependent on operator skill |

| Cost | Higher initial investment | Lower upfront cost |

| Maintenance | Advanced diagnostics required | Standard mechanical upkeep |

| Field Data Integration | Seamless with IoT and sensors | Limited data integration |

| Safety | Reduced human risk | Higher risk from human error |

| Applications | Planting, spraying, harvesting | Versatile but manual |

Introduction to Tractor Technologies in Precision Agriculture

Autonomous tractors in precision agriculture integrate GPS, sensors, and machine learning to perform field operations with enhanced accuracy and efficiency compared to conventional tractors. These advanced technologies enable precise seed placement, optimized fertilizer application, and real-time data collection, reducing human error and labor costs. Conventional tractors rely heavily on manual control and basic automation, limiting their ability to maximize yield and resource management.

Evolution of Autonomous vs Conventional Tractors

Autonomous tractors have significantly evolved with advanced GPS, AI-driven navigation, and real-time data analytics, surpassing conventional tractors in precision and efficiency for field operations. Conventional tractors rely heavily on manual control and operator expertise, limiting their ability to optimize resource use and adapt to varying field conditions. The integration of autonomous technology reduces labor costs, enhances crop yield prediction, and increases operational safety compared to traditional farming machinery.

Operational Efficiency: Autonomous vs Conventional Tractors

Autonomous tractors enhance operational efficiency by reducing labor costs and enabling continuous fieldwork without operator fatigue, leading to faster completion of tasks compared to conventional tractors. These vehicles utilize GPS-guided navigation and real-time data analytics to optimize fuel consumption and minimize overlap or gaps in field coverage, increasing productivity per acre. Conventional tractors rely heavily on operator skill and availability, which can limit operational hours and precision, ultimately affecting overall efficiency in large-scale farming operations.

Precision in Field Tasks: Autonomy and Human Control

Autonomous tractors leverage advanced GPS, LiDAR, and machine learning algorithms to achieve centimeter-level accuracy in field operations, significantly reducing overlap and input waste compared to conventional tractors. These self-driving machines enable precise seed placement, variable-rate fertilization, and real-time field monitoring with minimal human intervention, enhancing efficiency and crop yield. Conventional tractors rely heavily on operator skill and manual adjustments, often resulting in less consistent precision and higher variability in field task execution.

Cost-Benefit Analysis: Investment and ROI Comparison

Autonomous tractors typically require an initial investment 20-40% higher than conventional tractors due to advanced sensors, GPS, and AI systems, but they reduce labor costs by up to 60% and increase operational efficiency by 15-25%. Over a 5-year period, ROI analysis shows autonomous tractors can deliver 10-30% higher returns through reduced fuel consumption, optimized field coverage, and minimized downtime. Conventional tractors have lower upfront costs but incur higher ongoing labor and maintenance expenses, leading to slower breakeven points in field operations.

Impact on Crop Yield and Resource Utilization

Autonomous tractors enhance crop yield by leveraging real-time data analytics and GPS-guided precision, enabling targeted planting and fertilization that reduce nutrient wastage. Compared to conventional tractors, autonomous systems optimize resource utilization by minimizing fuel consumption and labor costs through automated, continuous operations. Field studies indicate up to 15% yield improvement and 20% resource savings using autonomous technology, promoting sustainable agriculture practices.

Labor Requirements and Workforce Transformation

Autonomous tractors drastically reduce labor requirements by operating continuously without the need for human intervention, enabling farms to optimize workforce allocation and minimize reliance on manual labor. Conventional tractors demand skilled operators for effective field operations, resulting in higher labor costs and increased workforce presence on-site. The transition to autonomous machinery drives workforce transformation, emphasizing technical skills in monitoring and maintaining equipment rather than traditional driving expertise.

Environmental Sustainability and Fuel Consumption

Autonomous tractors significantly reduce fuel consumption by optimizing routes and operating at consistent speeds, leading to lower greenhouse gas emissions compared to conventional tractors. Precision agriculture technologies integrated into autonomous tractors enable precise application of inputs, minimizing soil compaction and reducing chemical runoff that harms ecosystems. Studies show autonomous tractors can cut fuel use by up to 30%, supporting environmental sustainability through enhanced efficiency and reduced carbon footprint in field operations.

Challenges and Limitations of Autonomous Tractors

Autonomous tractors face challenges such as high initial investment costs, limited adaptability to complex terrains, and dependency on reliable GPS signals, which can hinder precise navigation in obstructed environments. Sensor malfunctions and software errors pose risks of operational downtime and reduced efficiency compared to conventional tractors operated by humans. Furthermore, regulatory constraints and the need for farmer training on autonomous systems present significant barriers to widespread adoption in precision agriculture.

Future Trends and Adoption in Precision Agriculture

Autonomous tractors are set to revolutionize field operations in precision agriculture by enhancing efficiency through GPS-guided navigation and real-time data integration, reducing labor costs and minimizing human error. Future trends indicate widespread adoption driven by advancements in AI, machine learning, and IoT connectivity, enabling precise variable-rate applications and continuous monitoring of crop health. Conventional tractors, while reliable, face gradual obsolescence as precision agriculture increasingly demands automation for scalability and sustainability in modern farming practices.

Related Important Terms

Full-Stack Autonomous Navigation

Full-stack autonomous navigation in tractors integrates advanced GPS, LiDAR, and AI technologies to precisely maneuver fields, significantly reducing labor costs and operational errors compared to conventional tractors. Autonomous tractors consistently optimize planting, spraying, and harvesting with minimal human intervention, enhancing crop yields and resource efficiency through real-time data processing and adaptive decision-making.

Swarm Tractor Management

Autonomous tractors equipped with advanced swarm management systems enable coordinated field operations that optimize planting, fertilizing, and harvesting by maintaining precise spacing and real-time communication among multiple units. Conventional tractors lack integrated swarm capabilities, resulting in less efficient coverage and increased fuel consumption during large-scale agricultural tasks.

Remote Fleet Orchestration

Autonomous tractors leverage advanced GPS, IoT sensors, and AI-driven remote fleet orchestration platforms to optimize field operations by enabling real-time monitoring, route planning, and task allocation without on-site human intervention. Conventional tractors lack integrated connectivity and automation capabilities, resulting in less efficient fleet management and limited scalability for precision agriculture applications.

Edge-based Sensor Fusion

Autonomous tractors equipped with edge-based sensor fusion integrate real-time data from LiDAR, cameras, and GPS to optimize field operations with higher precision and reduced latency compared to conventional tractors relying on manual control and less sophisticated sensing. This advanced sensor fusion enables autonomous tractors to perform tasks such as soil analysis, planting, and harvesting more efficiently, enhancing productivity and reducing operational costs in precision agriculture.

Dynamic Route Optimization

Autonomous tractors leverage dynamic route optimization algorithms that continuously adjust paths based on real-time field data, significantly enhancing fuel efficiency and reducing operational time compared to conventional tractors that follow static, pre-planned routes. This technology enables precise navigation around obstacles and variable terrain, maximizing productivity and minimizing soil compaction during field operations.

Autonomous Implement Control

Autonomous tractors equipped with advanced implement control systems enable precise, real-time adjustments to optimize field operations, reducing human error and increasing efficiency compared to conventional tractors. These systems leverage GPS, sensors, and AI algorithms to automatically manage implement functions such as seed depth, fertilizer application, and soil condition monitoring, enhancing crop yield and resource management.

Real-Time In-Field Decision Support

Autonomous tractors leverage advanced sensors and AI algorithms to provide real-time in-field decision support, optimizing planting, fertilizing, and harvesting processes with unprecedented precision and efficiency. Conventional tractors rely heavily on operator expertise and manual adjustments, limiting their responsiveness to dynamic field conditions and real-time data analysis.

Geofence-Based Operation Restrictions

Autonomous tractors equipped with geofence-based operation restrictions enable precise boundary adherence, minimizing crop damage and optimizing field management by preventing machinery from operating outside designated zones. In contrast, conventional tractors lack real-time geospatial constraints, increasing the risk of human error and inefficient field coverage.

Predictive Maintenance Algorithms

Autonomous tractors leverage predictive maintenance algorithms that analyze real-time sensor data to forecast mechanical failures, significantly reducing downtime and repair costs compared to conventional tractors. These advanced algorithms optimize field operations by scheduling maintenance proactively based on data-driven insights, enhancing overall equipment efficiency and productivity.

Human Override Fail-Safes

Autonomous tractors are equipped with advanced human override fail-safes, including manual control modes and emergency stop functions, ensuring operator intervention during system malfunctions or unexpected obstacles. In contrast, conventional tractors rely solely on direct human control, lacking automated safety protocols but allowing immediate manual response without technological dependency.

Autonomous Tractors vs Conventional Tractors for Field Operations Infographic

agridif.com

agridif.com