Reeling silk produces long, continuous fibers that result in a smooth, lustrous yarn ideal for high-quality silk products. Spun silk uses shorter fibers that are carded and twisted together, creating a yarn with a slightly coarser texture and less sheen. Choosing between reeling and spun silk depends on the desired fabric texture and end-use applications in sericulture.

Table of Comparison

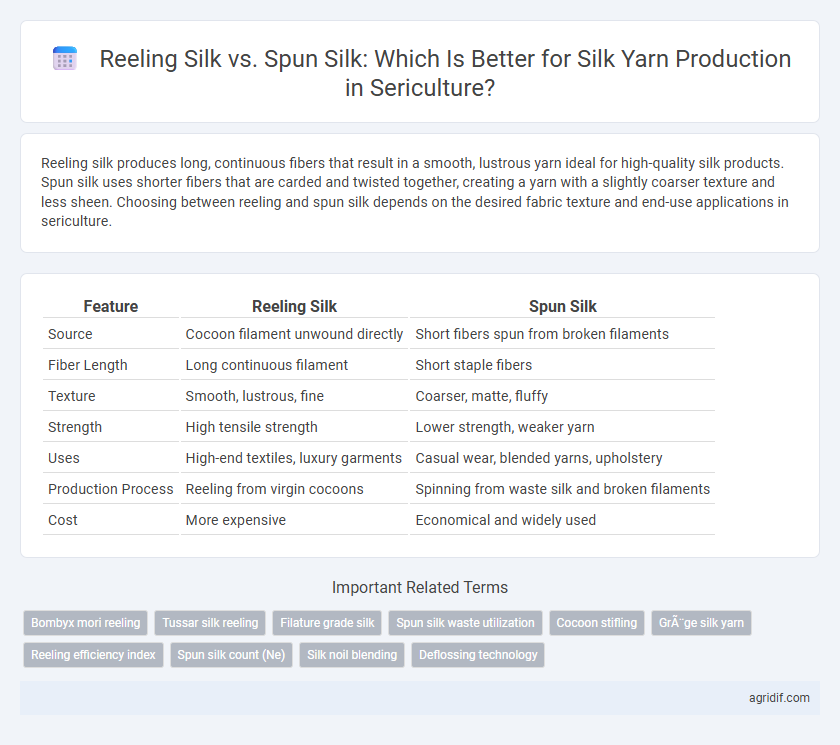

| Feature | Reeling Silk | Spun Silk |

|---|---|---|

| Source | Cocoon filament unwound directly | Short fibers spun from broken filaments |

| Fiber Length | Long continuous filament | Short staple fibers |

| Texture | Smooth, lustrous, fine | Coarser, matte, fluffy |

| Strength | High tensile strength | Lower strength, weaker yarn |

| Uses | High-end textiles, luxury garments | Casual wear, blended yarns, upholstery |

| Production Process | Reeling from virgin cocoons | Spinning from waste silk and broken filaments |

| Cost | More expensive | Economical and widely used |

Introduction to Sericulture: Reeling Silk vs Spun Silk

Reeling silk and spun silk are two primary methods of producing silk yarn in sericulture, each offering distinct qualities and applications. Reeling silk involves carefully unwinding long, continuous filaments from silkworm cocoons, resulting in smooth, lustrous yarn known for its strength and uniformity. Spun silk, created by spinning shorter fibers collected from damaged or waste cocoons, produces a more textured and matte yarn ideal for textile blends and diverse fabric uses.

Definition and Process of Reeling Silk

Reeling silk involves unwinding long, continuous filaments from the cocoon of the silkworm, producing smooth, fine, and lustrous silk yarn essential for high-quality fabrics. This process requires boiling the cocoons to soften the sericin, then carefully extracting multiple filaments simultaneously to create a single thread of reeling silk. Unlike spun silk, which is made from shorter fibers by spinning, reeling silk maintains fiber integrity and length, resulting in superior strength and shimmer in the finished yarn.

Understanding Spun Silk Production

Spun silk production involves using short silk fibers that are either broken or leftover from the reeling process, which makes it distinct from reeling silk yarn produced from long, continuous filaments. This method results in a yarn with a slightly rougher texture and lower tensile strength compared to reeled silk but is more cost-effective and suitable for blending with other fibers. Understanding the nuances of spun silk production is essential for optimizing fabric properties in sericulture-based textile manufacturing.

Key Differences Between Reeling Silk and Spun Silk

Reeling silk is produced by unwinding long, continuous filaments from silk cocoons, resulting in smooth, strong, and lustrous yarn ideal for high-quality fabrics. Spun silk, on the other hand, is made from shorter silk fibers that are carded and spun, producing a yarn with a textured feel and less sheen, suitable for more affordable and durable textiles. The key differences lie in filament length, texture, strength, and fabric quality, with reeling silk offering superior uniformity and softness compared to spun silk.

Raw Material Sources for Reeling and Spun Silk

Reeling silk is produced from long, continuous filaments obtained directly from the cocoons of mulberry silkworms, primarily Bombyx mori, ensuring high-quality raw material with uniform fiber length. Spun silk, on the other hand, is made from staple fibers derived from shorter, waste, or damaged cocoons and defective filaments, often including non-mulberry silks like eri or muga varieties. The raw material source difference significantly impacts yarn strength, luster, and texture, with reeling silk demanding pristine cocoon harvesting and spun silk utilizing by-products and lower-grade silk fibers.

Quality Comparison: Texture and Strength

Reeling silk yarn, produced by unwinding long, continuous filaments from silk cocoons, exhibits superior texture and strength, characterized by a smooth, lustrous surface and high tensile durability ideal for fine textiles. Spun silk yarn, made by spinning shorter fibers from damaged or pierced cocoons, offers a coarser texture with lower tensile strength, resulting in a less uniform and more matte finish suitable for more rustic fabric applications. Quality comparison reveals reeling silk's prominence in luxury silk production due to its consistent filament length and enhanced durability, whereas spun silk provides affordability with a distinct tactile feel and moderate strength.

Applications in the Textile Industry

Reeling silk, characterized by its long, continuous filaments, is preferred in high-end textiles for its smooth texture and strength, ideal for fine fabrics such as silk charmeuse and chiffon. Spun silk, made from shorter fibers twisted together, is widely used in more durable, affordable textiles like upholstery and heavy garments due to its robust and slightly textured finish. The choice between reeling and spun silk significantly impacts fabric quality, durability, and application in fashion, home decor, and industrial textiles.

Economic Considerations in Silk Yarn Production

Reeling silk commands higher market prices due to its superior strength, uniformity, and luster, making it economically advantageous for producing premium silk textiles. In contrast, spun silk, derived from shorter fibers and waste, offers lower production costs but yields less durable yarn with a coarser texture, appealing primarily to budget-conscious markets. Producers must balance the higher investment and processing time of reeling silk against the cost-effectiveness and faster production cycles of spun silk to optimize profitability in silk yarn manufacturing.

Environmental Impact: Reeling Silk vs Spun Silk

Reeling silk production generates less waste and consumes less energy compared to spun silk, as it involves unwinding silk filaments directly from cocoons, maintaining the fiber's natural strength and luster. Spun silk, produced by spinning shorter fiber waste and broken filaments, tends to have a higher environmental footprint due to additional processing steps and increased energy use. The lower resource consumption and reduced chemical treatments involved in reeling silk contribute to its smaller environmental impact compared to the more labor-intensive spun silk method.

Future Trends in Silk Yarn Manufacturing

Reeling silk and spun silk represent two distinct methods of producing silk yarn, with reeling silk yielding long, continuous filaments prized for strength and luster, while spun silk consists of shorter fibers twisted together, offering versatility and cost-effectiveness. Future trends in silk yarn manufacturing emphasize sustainable practices, advanced biotechnologies for enhanced fiber quality, and hybrid yarns combining reeling and spun silk to optimize performance and market appeal. Integration of AI-driven quality control and eco-friendly processing technologies are projected to revolutionize the sericulture industry, meeting growing demand for high-performance, sustainable silk textiles.

Related Important Terms

Bombyx mori reeling

Reeling silk from Bombyx mori produces long, continuous filaments with superior tensile strength and smooth texture, ideal for high-quality silk yarn. Spun silk, made from shorter fibers and silk waste, results in a coarser texture with less durability, suitable for lower-grade silk products.

Tussar silk reeling

Reeling silk from Tussar silk cocoons preserves long continuous filaments, resulting in smooth, lustrous yarn ideal for high-quality textiles; in contrast, spun silk for Tussar involves short fibers twisted together, producing a coarser, less uniform yarn. Reeling maintains the natural texture and strength specific to Tussar silk, enhancing its value in premium silk fabric production.

Filature grade silk

Reeling silk, derived from long, continuous fibers obtained by unwinding cocoons, offers superior strength, smoothness, and luster ideal for Filature grade silk yarn production. Spun silk, composed of shorter fibers from broken or damaged cocoons, results in a rougher texture and lower durability, making it less suitable for high-quality Filature silk threads.

Spun silk waste utilization

Spun silk yarn is produced from silk waste fibers, maximizing resource efficiency by reprocessing broken cocoons, defective filaments, and sericin-coated remnants, contrasting with the continuous filament extraction in reeling silk. Utilizing spun silk waste supports sustainable sericulture by reducing raw material waste and offering a cost-effective alternative for textile production.

Cocoon stifling

Cocoon stifling, a critical process in sericulture, directly influences the quality of silk yarn by determining whether the fibers can be reeled or must be spun. Proper stifling preserves the filament's integrity enabling smooth reeling of long silk strands, while improper or delayed stifling leads to filament breakage, making spun silk yarn from shorter fibers the alternative.

Grège silk yarn

Reeling silk produces long, continuous filaments ideal for high-quality Grege silk yarn characterized by its smooth texture and natural sheen, whereas spun silk yarn consists of shorter fibers twisted together, resulting in a coarser and less lustrous fabric. Grege silk yarn from reeling retains the raw, unbleached sericin coating, enhancing strength and durability for premium silk textile applications.

Reeling efficiency index

Reeling silk exhibits a higher reeling efficiency index compared to spun silk, due to the intact filament extraction from silkworm cocoons resulting in smoother, stronger yarn with minimal breakage. This efficiency enhances production quality and economic value by reducing yarn waste and improving tensile strength in sericulture.

Spun silk count (Ne)

Spun silk yarn, measured in Ne (Number English), typically ranges from 5 to 20 Ne, with finer counts indicating superior fineness and softness suitable for delicate fabrics. Compared to reeling silk, spun silk's higher Ne count variability reflects its production from shorter fibers, resulting in a slightly coarser texture but increased yarn strength and cost-effectiveness in textile manufacturing.

Silk noil blending

Reeling silk, produced from long filaments, offers superior luster and strength, while spun silk, derived from short fibers or silk noil, provides a textured, matte finish ideal for blending with other fibers to enhance fabric durability and cost-effectiveness. Silk noil blending with spun silk creates versatile yarns that balance softness and resilience, making them suitable for varied textile applications where both aesthetics and functionality are desired.

Deflossing technology

Reeling silk produces long, continuous filaments with superior strength and luster, while spun silk results from shorter fibers twisted together, often less uniform and weaker. Advanced deflossing technology enhances the quality of reeling silk yarn by efficiently removing sericin and impurities, ensuring smoother, finer threads compared to traditional spun silk processing.

Reeling silk vs Spun silk for silk yarn Infographic

agridif.com

agridif.com