Wet cocoons retain moisture, making them ideal for immediate reeling processes as they yield stronger, finer silk fibers with minimal breakage. Dry cocoons, having reduced moisture content, are easier to store and transport but require rehydration before reeling, which can affect fiber quality and increase processing time. Choosing between wet and dry cocoons depends on balancing processing efficiency, storage needs, and silk quality requirements in sericulture post-harvest management.

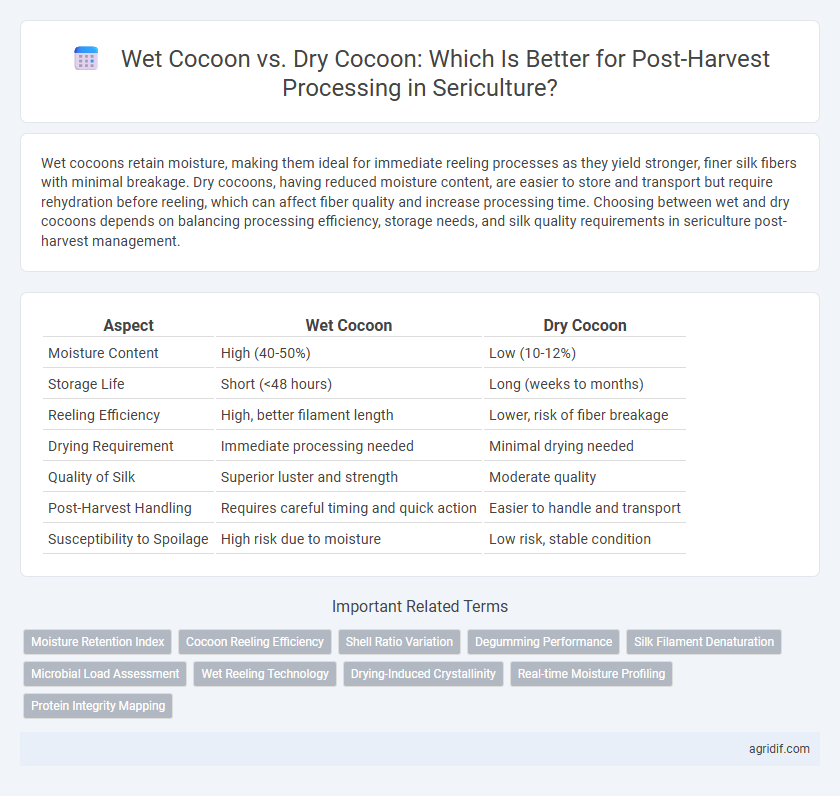

Table of Comparison

| Aspect | Wet Cocoon | Dry Cocoon |

|---|---|---|

| Moisture Content | High (40-50%) | Low (10-12%) |

| Storage Life | Short (<48 hours) | Long (weeks to months) |

| Reeling Efficiency | High, better filament length | Lower, risk of fiber breakage |

| Drying Requirement | Immediate processing needed | Minimal drying needed |

| Quality of Silk | Superior luster and strength | Moderate quality |

| Post-Harvest Handling | Requires careful timing and quick action | Easier to handle and transport |

| Susceptibility to Spoilage | High risk due to moisture | Low risk, stable condition |

Introduction to Wet and Dry Cocoons in Sericulture

Wet cocoons retain high moisture content immediately after harvesting, facilitating easier reeling but requiring swift processing to prevent microbial degradation. Dry cocoons undergo natural or artificial drying to lower moisture levels, enhancing storage stability and allowing for extended preservation before reeling. The choice between wet and dry cocoons in sericulture directly impacts silk quality, yield efficiency, and post-harvest handling protocols.

Harvesting Techniques: Wet Cocoon vs Dry Cocoon

Wet cocoon harvesting involves collecting fresh, moist cocoons immediately after silk worm pupation, ensuring high silk filament quality due to reduced drying cracks but requiring rapid processing to prevent spoilage. Dry cocoon harvesting allows natural drying before collection, offering easier storage and transportation but often causing reduced silk luster and filament length due to drying-induced damage. Selecting between wet and dry cocoon techniques impacts the efficiency of reeling processes and overall silk yield in post-harvest sericulture operations.

Moisture Content: Impacts on Cocoon Quality

Wet cocoons typically retain moisture content between 30-40%, which provides easier reelability but increases the risk of microbial growth and reduces shelf life. Dry cocoons, with moisture content around 12-15%, offer better storability and lower spoilage but require rehydration before reeling, potentially impacting silk filament length. Managing moisture content precisely is crucial to maintaining cocoon quality and optimizing silk yield during post-harvest processing.

Post-Harvest Handling Differences

Wet cocoons retain high moisture content, requiring immediate processing to prevent microbial degradation, whereas dry cocoons have reduced moisture, allowing longer storage without quality loss. Post-harvest handling for wet cocoons involves prompt boiling to extract sericin and stop fermentation, while dry cocoons need controlled rehydration before reeling. Efficient management of moisture levels in wet versus dry cocoons is crucial to optimize silk filament quality and minimize spoilage during sericulture processing.

Silk Reeling Efficiency: Wet vs Dry Cocoons

Wet cocoons retain higher moisture content, resulting in softer silk fibers that enhance reeling smoothness but may lower raw silk yield due to increased filament breakage. Dry cocoons, with reduced moisture, produce more brittle fibers that can increase filament breakage during reeling, decreasing silk reeling efficiency. Optimal post-harvest processing balances moisture levels to maximize filament length and tensile strength, improving overall silk reeling productivity.

Yield and Quality of Silk Fiber

Wet cocoon processing yields higher quantities of silk fiber due to increased moisture content, which facilitates easier filament extraction and reduces breakage. However, dry cocoons produce silk with superior fiber quality, characterized by enhanced luster, tensile strength, and uniformity, as moisture removal minimizes filament damage. Optimizing cocoon moisture levels during post-harvest processing is crucial to balance maximum silk yield with premium fiber quality in sericulture.

Storage and Transportation Considerations

Wet cocoons, containing high moisture content, require immediate processing or specialized refrigeration during storage and transportation to prevent fungal growth and quality degradation. In contrast, dry cocoons offer greater storage stability and easier handling without refrigeration, reducing logistics costs and extending shelf life. Optimal post-harvest management balances moisture levels to maintain cocoon integrity and ensure efficient silk extraction.

Economic Implications for Farmers

Wet cocoon harvesting requires immediate processing and higher labor costs due to moisture content, impacting farmers' cash flow and storage ability. Dry cocoon handling reduces weight, lowers transportation expenses, and allows longer storage, enhancing market flexibility but potentially compromising silk quality if not managed properly. Farmers must balance immediate income needs with long-term product quality to optimize economic returns in sericulture.

Challenges in Processing Wet and Dry Cocoons

Wet cocoons retain high moisture content, making them prone to fungal growth and requiring immediate and careful drying to prevent quality degradation. Dry cocoons, although easier to store, demand precise humidity control to avoid brittleness and fiber damage during processing. Both types pose challenges in maintaining sericin integrity and silk filament strength, necessitating tailored handling techniques for optimal silk yield.

Future Trends and Innovations in Cocoon Processing

Future trends in sericulture emphasize advanced techniques for wet cocoon processing to enhance moisture retention, reducing wastage and improving silk quality through bioengineered preservatives and controlled drying systems. Innovations in dry cocoon processing include automated sorting and grading technologies utilizing AI and machine learning for precise yield optimization and defect detection. Integration of IoT-based monitoring ensures real-time data analytics, promoting sustainable and efficient post-harvest silk production workflows.

Related Important Terms

Moisture Retention Index

Wet cocoons exhibit a high Moisture Retention Index, typically retaining 30-40% moisture, which facilitates easier reeling and reduces silk breakage. In contrast, dry cocoons have a lower Moisture Retention Index, around 10-15%, leading to increased brittleness and challenges in post-harvest processing efficiency.

Cocoon Reeling Efficiency

Wet cocoon reeling enhances cocoon reeling efficiency by maintaining higher sericin moisture content, facilitating smoother filament extraction and reducing breakage rates compared to dry cocoons. In contrast, dry cocoon reeling often results in lower filament quality due to rigid sericin bonds, leading to increased filament breakage and reduced yarn uniformity.

Shell Ratio Variation

Wet cocoon post-harvest processing retains higher moisture content, resulting in a lower shell ratio due to increased weight from water absorption. In contrast, dry cocoon processing reduces moisture, enhancing the shell ratio by concentrating the sericin and fibroin content, which improves silk yield quality.

Degumming Performance

Wet cocoons retain higher moisture content, facilitating easier sericin removal during degumming and resulting in smoother silk fibers with fewer imperfections. Dry cocoons require extended degumming time and harsher chemical treatment, which may compromise fiber strength and reduce overall silk quality in post-harvest processing.

Silk Filament Denaturation

Wet cocoon post-harvest processing involves retaining moisture, resulting in higher silk filament denaturation due to enzymatic activity and biodegradation, which reduces filament length and tensile strength. Dry cocoon processing minimizes moisture content, preserving filament integrity and enhancing silk quality by reducing protein denaturation and maintaining optimal fibroin properties.

Microbial Load Assessment

Wet cocoons retain higher moisture content, resulting in increased microbial load and faster deterioration during post-harvest processing compared to dry cocoons, which exhibit lower microbial contamination due to reduced water activity. Effective microbial load assessment in wet versus dry cocoons is crucial for optimizing storage conditions and improving silk quality by controlling bacterial and fungal proliferation.

Wet Reeling Technology

Wet cocoon processing involves reeling freshly harvested cocoons with high moisture content, preserving fibroin integrity and enhancing filament length and tensile strength; dry cocoon processing requires degumming and rehydration steps that can degrade fiber quality. Wet reeling technology optimizes sericulture output by enabling continuous filament extraction directly from wet cocoons, improving efficiency and silk quality compared to traditional dry cocoon methods.

Drying-Induced Crystallinity

Dry cocoon processing enhances drying-induced crystallinity, improving silk fibroin's structural integrity and resulting in superior fiber strength and luster compared to wet cocoons. Increased crystallinity during drying minimizes moisture retention, reducing defects and optimizing post-harvest quality for industrial silk production.

Real-time Moisture Profiling

Wet cocoons contain higher moisture content, typically around 30-40%, which requires immediate real-time moisture profiling to prevent fungal growth and ensure optimal drying conditions during post-harvest processing. In contrast, dry cocoons have moisture levels below 18%, allowing for more stable storage and streamlined processing, but still demand precise moisture monitoring to maintain quality and prevent brittleness in silk fibers.

Protein Integrity Mapping

Wet cocoon processing preserves sericin protein integrity better than dry cocoon methods by maintaining higher moisture content, which reduces protein denaturation during reeling. Protein integrity mapping reveals that wet cocoon cocoons yield superior fibroin quality, enhancing silk thread strength and luster in post-harvest sericulture operations.

Wet cocoon vs Dry cocoon for post-harvest processing Infographic

agridif.com

agridif.com