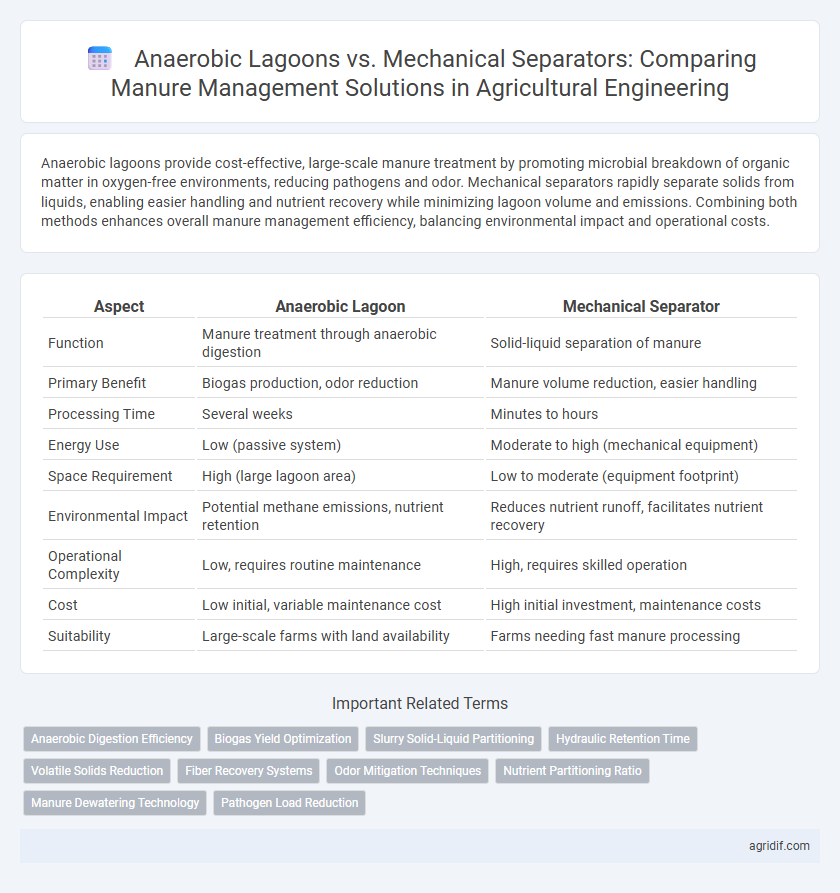

Anaerobic lagoons provide cost-effective, large-scale manure treatment by promoting microbial breakdown of organic matter in oxygen-free environments, reducing pathogens and odor. Mechanical separators rapidly separate solids from liquids, enabling easier handling and nutrient recovery while minimizing lagoon volume and emissions. Combining both methods enhances overall manure management efficiency, balancing environmental impact and operational costs.

Table of Comparison

| Aspect | Anaerobic Lagoon | Mechanical Separator |

|---|---|---|

| Function | Manure treatment through anaerobic digestion | Solid-liquid separation of manure |

| Primary Benefit | Biogas production, odor reduction | Manure volume reduction, easier handling |

| Processing Time | Several weeks | Minutes to hours |

| Energy Use | Low (passive system) | Moderate to high (mechanical equipment) |

| Space Requirement | High (large lagoon area) | Low to moderate (equipment footprint) |

| Environmental Impact | Potential methane emissions, nutrient retention | Reduces nutrient runoff, facilitates nutrient recovery |

| Operational Complexity | Low, requires routine maintenance | High, requires skilled operation |

| Cost | Low initial, variable maintenance cost | High initial investment, maintenance costs |

| Suitability | Large-scale farms with land availability | Farms needing fast manure processing |

Introduction to Manure Management in Agriculture

Anaerobic lagoons and mechanical separators are critical technologies in manure management that reduce environmental impact and enhance nutrient recovery in agriculture. Anaerobic lagoons utilize microbial digestion under oxygen-free conditions to break down organic matter, producing biogas and stabilizing waste. Mechanical separators physically separate solids from liquids, improving manure handling efficiency and enabling targeted nutrient application to crops.

Overview of Anaerobic Lagoons

Anaerobic lagoons are large, lined basins designed to treat and store livestock manure through microbial decomposition in oxygen-free conditions, significantly reducing pathogens and odor. These lagoons rely on natural anaerobic digestion processes to break down organic matter, producing biogas composed primarily of methane and carbon dioxide. Compared to mechanical separators, anaerobic lagoons offer cost-effective long-term manure stabilization but require substantial land area and careful management to prevent environmental contamination.

Mechanical Separators: Principles and Functionality

Mechanical separators for manure management operate by physically dividing solid and liquid components through screening, centrifugation, or screw press mechanisms, enhancing nutrient recovery and reducing volume for transport. These systems optimize manure handling by improving the drying rate of solids, enabling their reuse as bedding or fertilizer, and minimizing environmental impact through reduced nutrient runoff. Integrating mechanical separators with anaerobic lagoons can enhance overall system efficiency, allowing for better resource utilization and enhanced waste treatment in agricultural operations.

Comparative Efficiency: Anaerobic Lagoon vs Mechanical Separator

Anaerobic lagoons offer efficient large-scale manure storage and pathogen reduction through microbial decomposition, significantly lowering biochemical oxygen demand (BOD) and volatile solids. Mechanical separators enhance manure management by rapidly separating solids from liquids, improving nutrient recovery and reducing the volume of material requiring treatment or land application. Comparative efficiency depends on farm scale and manure type, with anaerobic lagoons excelling in stabilization and odor control, while mechanical separators provide faster processing and better solid-liquid partitioning for nutrient management.

Environmental Impact Assessment

Anaerobic lagoons effectively reduce methane emissions through controlled decomposition of manure but pose risks of groundwater contamination and odor release if not properly managed. Mechanical separators minimize nutrient runoff by extracting solids from liquid manure, enhancing nutrient recycling and reducing the potential for water pollution. Comparing environmental impact assessments reveals that integrating both technologies optimizes manure treatment, balancing greenhouse gas mitigation with nutrient management.

Cost Analysis and Economic Considerations

Anaerobic lagoons typically offer lower upfront construction costs and reduced operational expenses compared to mechanical separators, making them economically viable for large-scale manure management in livestock operations. Mechanical separators involve higher capital investment and maintenance costs but enable manure volume reduction and nutrient recovery, potentially increasing revenue through byproducts like bedding material or fertilizer. Cost analysis should consider site-specific factors such as available land, manure volume, and regulatory requirements to determine the most cost-effective manure management technology.

Manure By-Products and Nutrient Recovery

Anaerobic lagoons efficiently convert manure organic matter into biogas, enabling nutrient-rich effluent recovery for crop fertilization, while mechanical separators physically divide solids and liquids, facilitating targeted nutrient management and improved handling of manure by-products. Mechanical separators enhance phosphorus recovery through solid fraction collection, supporting sustainable nutrient recycling, whereas anaerobic lagoons primarily focus on nitrogen mineralization and pathogen reduction. Combining both technologies optimizes nutrient capture, with anaerobic lagoons providing energy generation and pathogen control, and separators improving nutrient concentration and transport efficiency.

Odor Control and Air Quality Management

Anaerobic lagoons reduce odor emissions by promoting microbial breakdown of organic material under oxygen-free conditions, effectively controlling volatile compounds like hydrogen sulfide and ammonia. Mechanical separators physically remove solids from manure, minimizing odor sources by reducing the amount of decomposable material and improving air quality through decreased particulate matter release. Both technologies contribute to air quality management, but anaerobic lagoons excel in odor neutralization via biological processes, while mechanical separators primarily prevent odor generation through solid-liquid separation.

System Maintenance and Operational Requirements

Anaerobic lagoons require routine monitoring of temperature, pH, and sludge accumulation levels to maintain microbial activity and prevent system failure. Mechanical separators demand frequent inspection and cleaning of screens or rotating parts to avoid clogging and ensure optimal solids-liquid separation efficiency. Both systems necessitate timely maintenance to sustain performance, though mechanical separators typically involve higher labor intensity and equipment upkeep costs.

Recommendations for Optimal Manure Management

For optimal manure management, integrating anaerobic lagoons with mechanical separators enhances nutrient recovery and reduces environmental impact. Anaerobic lagoons efficiently decompose organic matter and produce biogas, while mechanical separators reduce solids content, facilitating easier handling and application of liquid effluent. Combining these technologies supports sustainable nutrient recycling and mitigates greenhouse gas emissions in agricultural operations.

Related Important Terms

Anaerobic Digestion Efficiency

Anaerobic lagoons offer lower anaerobic digestion efficiency compared to mechanical separators, as lagoons rely on natural microbial processes that can be slower and less controlled, leading to incomplete organic matter breakdown. Mechanical separators enhance manure management by concentrating solids and optimizing conditions for anaerobic digesters, thereby increasing biogas production and nutrient recovery efficiency.

Biogas Yield Optimization

Anaerobic lagoons enhance biogas yield by providing an oxygen-free environment where microorganisms efficiently break down organic matter in manure, producing methane-rich biogas over time. Mechanical separators reduce solids content before digestion, improving feedstock homogeneity and increasing biogas production rates by optimizing microbial access to degradable substrates.

Slurry Solid-Liquid Partitioning

Anaerobic lagoons facilitate natural solid-liquid separation through sedimentation, retaining solids at the bottom while liquid effluent is managed separately, promoting nutrient stabilization and pathogen reduction over time. Mechanical separators actively partition slurry by extracting solids via screens or centrifuges, enabling faster processing and improved nutrient recovery for subsequent land application or bedding use.

Hydraulic Retention Time

Anaerobic lagoons typically require a longer hydraulic retention time, often ranging from 20 to 60 days, allowing for effective microbial breakdown of organic matter in manure. Mechanical separators significantly reduce hydraulic retention time by quickly separating solids from liquids, facilitating faster manure processing and reducing lagoon volume requirements.

Volatile Solids Reduction

Anaerobic lagoons achieve substantial volatile solids reduction by promoting microbial digestion in an oxygen-free environment, leading to organic matter breakdown and biogas production. Mechanical separators primarily isolate solids from manure but result in minimal volatile solids reduction since they do not facilitate microbial degradation.

Fiber Recovery Systems

Anaerobic lagoons efficiently break down manure organic matter through microbial activity but offer limited fiber recovery, while mechanical separators excel at extracting high-quality fiber solids for reuse in bedding or feed. Integrating mechanical fiber recovery systems reduces manure volume, enhances nutrient management, and promotes sustainable recycling of valuable fibrous material in agricultural operations.

Odor Mitigation Techniques

Anaerobic lagoons reduce odor by promoting microbial breakdown of organic matter under oxygen-free conditions, significantly decreasing volatile compounds responsible for smell; mechanical separators minimize odors by physically removing solids from manure, thus limiting the substrate for anaerobic bacteria and reducing emission of odorous gases. Implementing these technologies enhances odor control in livestock waste management, with anaerobic lagoons offering biochemical treatment and mechanical separators providing immediate solid-liquid separation benefits.

Nutrient Partitioning Ratio

Anaerobic lagoons primarily retain nutrients in the liquid fraction, resulting in a nutrient partitioning ratio that favors nitrogen and phosphorus in the effluent, whereas mechanical separators redistribute nutrients by capturing a higher proportion of solids, concentrating phosphorus in the solid fraction. Optimizing nutrient partitioning ratio between these systems enhances targeted nutrient recovery for improved manure management and reduced environmental impact.

Manure Dewatering Technology

Anaerobic lagoons reduce manure volume by microbial digestion, producing biogas but require large land areas and longer retention times. Mechanical separators rapidly dewater manure, increasing solids concentration for easier handling and nutrient recovery while minimizing storage space and odor emissions.

Pathogen Load Reduction

Anaerobic lagoons reduce pathogen load by promoting microbial degradation under oxygen-free conditions, effectively decreasing bacteria like E. coli and Salmonella in manure storage. Mechanical separators physically remove solids that harbor pathogens, lowering pathogen concentration and improving solids management but may require supplementary treatment to achieve significant pathogen reduction.

Anaerobic lagoon vs Mechanical separator for manure management Infographic

agridif.com

agridif.com