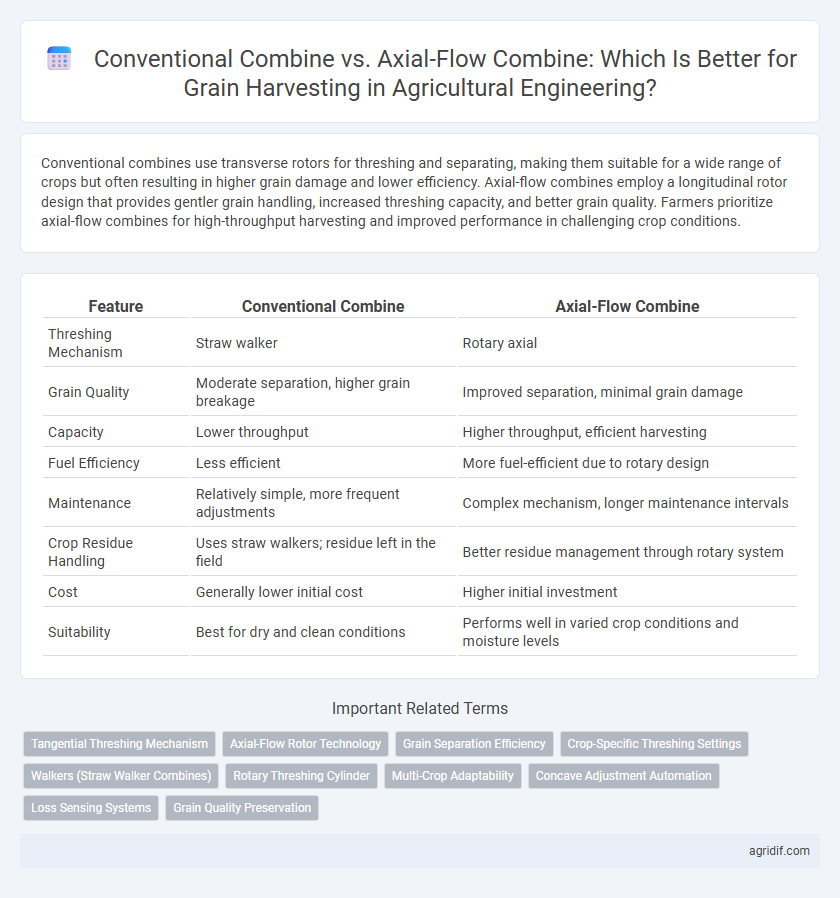

Conventional combines use transverse rotors for threshing and separating, making them suitable for a wide range of crops but often resulting in higher grain damage and lower efficiency. Axial-flow combines employ a longitudinal rotor design that provides gentler grain handling, increased threshing capacity, and better grain quality. Farmers prioritize axial-flow combines for high-throughput harvesting and improved performance in challenging crop conditions.

Table of Comparison

| Feature | Conventional Combine | Axial-Flow Combine |

|---|---|---|

| Threshing Mechanism | Straw walker | Rotary axial |

| Grain Quality | Moderate separation, higher grain breakage | Improved separation, minimal grain damage |

| Capacity | Lower throughput | Higher throughput, efficient harvesting |

| Fuel Efficiency | Less efficient | More fuel-efficient due to rotary design |

| Maintenance | Relatively simple, more frequent adjustments | Complex mechanism, longer maintenance intervals |

| Crop Residue Handling | Uses straw walkers; residue left in the field | Better residue management through rotary system |

| Cost | Generally lower initial cost | Higher initial investment |

| Suitability | Best for dry and clean conditions | Performs well in varied crop conditions and moisture levels |

Introduction: Importance of Combine Harvesters in Modern Grain Farming

Combine harvesters revolutionize modern grain farming by efficiently integrating reaping, threshing, and winnowing processes, significantly increasing productivity and reducing labor costs. The conventional combine, featuring a transverse threshing system, is valued for its simplicity and durability in diverse farming conditions. Axial-flow combines, utilizing a longitudinal rotor, offer improved grain quality and higher capacity, making them ideal for large-scale operations requiring advanced harvesting technology.

Overview of Conventional Combine Harvester Technology

Conventional combine harvesters use a transverse threshing cylinder and an apron or shaker shoe separation system, effectively separating grain from crop residue with moderate crop handling capacity. These machines are widely recognized for their durability and simplicity in maintenance, making them suitable for various grain types such as wheat, barley, and oats. Despite slower throughput compared to axial-flow combines, conventional combines remain cost-effective solutions in regions with smaller-scale farming operations.

Axial-Flow Combine: Design and Key Features

The Axial-Flow Combine utilizes a rotor-based threshing system that enhances grain separation efficiency and reduces crop damage compared to conventional cylinder combines. Its single rotor design improves material flow and throughput, enabling higher harvesting speeds and improved grain quality. Key features include adjustable rotor speed, a concave system for versatile crop handling, and advanced cleaning mechanisms for optimal grain recovery.

Threshing Mechanism: Conventional vs Axial-Flow Combines

Conventional combines use tangential threshing mechanisms where grain separation occurs through a cylindrical drum and concave system, relying on impact and friction forces. Axial-flow combines employ a longitudinal threshing cylinder combined with a helical rotor, enhancing grain separation efficiency and reducing damage by gently accelerating the crop material. The axial-flow design offers improved grain quality and higher throughput by minimizing kernel breakage compared to conventional threshing mechanisms.

Grain Quality and Loss Comparison

Conventional combines typically cause higher grain damage and loss due to their tangential threshing mechanism, which exerts greater force on the kernels. Axial-flow combines utilize a rotary threshing system that provides gentler grain handling, resulting in superior grain quality with reduced breakage and lower harvest losses. Studies indicate axial-flow combines can decrease grain loss by up to 15% compared to conventional designs, making them more efficient for preserving both yield and grain integrity.

Efficiency and Throughput in Various Crop Conditions

Conventional combines utilize transverse threshing systems that often require lower power but may struggle with grain separation efficiency in high-yield crops, impacting throughput during dense harvesting conditions. Axial-flow combines employ a rotor-based threshing mechanism providing higher grain quality and better capacity to handle diverse crop types, resulting in enhanced efficiency and increased throughput in variable moisture and crop density scenarios. Choice between these combines depends on specific crop conditions, with axial-flow models offering superior adaptability and performance in complex harvesting environments.

Maintenance and Operational Costs

Conventional combines typically have lower initial maintenance costs due to simpler designs but often require more frequent adjustments and repairs, increasing long-term operational expenses. Axial-flow combines feature advanced rotor technology that reduces mechanical wear and decreases the need for routine maintenance, leading to lower overall maintenance costs despite higher upfront investment. Operational efficiency in axial-flow combines also results in reduced fuel consumption and less downtime, thereby minimizing total operational costs compared to conventional models.

Adaptability to Crop Types and Field Conditions

Conventional combines utilize transverse threshing cylinders ideal for crops like wheat and barley, but they often struggle with high-moisture or lodged crops, limiting their adaptability across diverse field conditions. Axial-flow combines employ a longitudinal rotor system that offers gentler grain handling and superior separation efficiency, enhancing performance in varied crop types such as corn, soybeans, and rice under challenging terrain or uneven fields. This rotor design also reduces grain damage and loss, making axial-flow combines more versatile and effective for a wide range of harvesting environments.

Technological Advancements in Combine Harvesters

Conventional combine harvesters utilize a transverse threshing system that provides effective grain separation but often results in higher grain damage and lower throughput compared to axial-flow combines. Axial-flow combines incorporate a longitudinal rotor design that enhances threshing efficiency, reduces grain damage, and improves overall harvesting capacity through continuous crop flow and advanced material handling. Recent technological advancements include GPS integration, yield mapping, and automated controls, which significantly boost operational precision and productivity in both combine types, with axial-flow models leading in innovation adoption.

Conclusion: Choosing the Right Combine for Grain Harvesting Needs

Choosing the right combine for grain harvesting depends on specific crop types, field conditions, and operational efficiency requirements. Conventional combines offer durability and are effective for varied crops with heavier residue, while axial-flow combines provide smoother threshing and higher grain quality, ideal for wheat and soybeans. Evaluating machine capacity, maintenance, and grain handling ensures optimized performance and profitability in agricultural operations.

Related Important Terms

Tangential Threshing Mechanism

Conventional combines utilize a tangential threshing mechanism where the concave and cylinder rotate in opposite directions, providing effective grain separation but causing higher grain damage and loss. Axial-flow combines eliminate this tangential interaction by employing a longitudinal rotor threshing system, significantly improving grain quality and reducing crop loss during harvesting.

Axial-Flow Rotor Technology

Axial-flow rotor technology in combines enhances grain harvesting efficiency by providing continuous threshing and separating, reducing grain damage and losses compared to conventional combine systems with tangential threshing. This technology utilizes a single inclined rotor that gently processes crops, improving throughput capacity, grain quality, and fuel efficiency while minimizing mechanical wear.

Grain Separation Efficiency

Axial-flow combines utilize a longitudinal rotor design that delivers higher grain separation efficiency by reducing grain damage and improving threshing capacity compared to conventional combines with transverse rotors. This design ensures more effective separation with fewer losses, enhancing overall harvesting performance in diverse crop conditions.

Crop-Specific Threshing Settings

Conventional combines feature tangential threshing systems offering adjustable settings suited for a variety of crops but may cause higher grain damage in delicate crops like soybeans. Axial-flow combines use a single axial rotor design providing gentler, continuous threshing with customizable crop-specific settings that improve grain quality and minimize losses, especially in corn and wheat.

Walkers (Straw Walker Combines)

Straw walker combines utilize a series of oscillating walkers to separate grain from crop residue, providing effective threshing but lower throughput compared to axial-flow combines that employ rotor-based threshing for higher efficiency and gentler grain handling. Walkers excel in durability and suitability for heavier, wetter crops, while axial-flow combines offer superior separation and reduced grain damage, making them more suitable for high-capacity harvesting operations.

Rotary Threshing Cylinder

Conventional combines utilize a transverse threshing cylinder that separates grain through impact and friction, often resulting in higher grain damage and lower throughput compared to axial-flow combines. The axial-flow combine employs a rotary threshing cylinder with a longitudinal rotor that gently threshes and separates grain, enhancing efficiency, reducing breakage, and improving grain quality during harvesting.

Multi-Crop Adaptability

Conventional combines utilize transverse threshing mechanisms that limit multi-crop adaptability, making them less efficient for varying grain types. Axial-flow combines employ a longitudinal rotor design that enhances multi-crop adaptability by providing gentle crop handling and uniform threshing across diverse grain varieties.

Concave Adjustment Automation

Axial-flow combines feature advanced concave adjustment automation systems that optimize threshing efficiency by continuously adapting clearance based on grain and crop conditions, significantly reducing grain damage and losses compared to conventional combines. Conventional combines rely on manual concave adjustments, which are less precise and often lead to suboptimal threshing performance and higher operator fatigue.

Loss Sensing Systems

Loss sensing systems in axial-flow combines utilize advanced sensors and real-time monitoring to detect grain loss with higher accuracy compared to conventional combines, enhancing harvesting efficiency. Conventional combines primarily rely on mechanical methods for loss detection, which may lag in responsiveness and precision, leading to suboptimal grain recovery.

Grain Quality Preservation

Conventional combines use transverse threshing which often causes more grain breakage and higher impurity levels, negatively impacting grain quality preservation. Axial-flow combines utilize a longitudinal threshing and separation system that provides gentler crop handling, resulting in better kernel integrity and lower grain damage during harvesting.

Conventional combine vs Axial-flow combine for grain harvesting Infographic

agridif.com

agridif.com