Combine harvesters significantly increase efficiency in grain crop harvesting by integrating reaping, threshing, and winnowing into a single operation, reducing labor and time requirements. Traditional harvesting methods rely heavily on manual labor and separate processes, which are more time-consuming and less consistent in grain quality. The mechanized approach of combine harvesters enhances productivity, minimizes crop losses, and supports large-scale farming operations effectively.

Table of Comparison

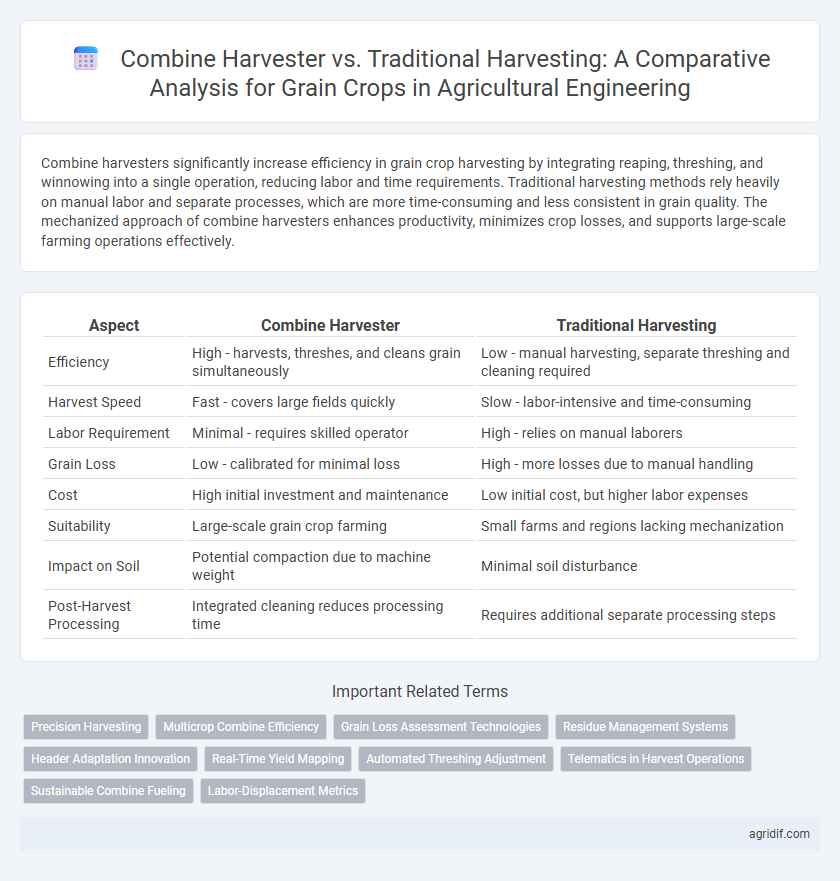

| Aspect | Combine Harvester | Traditional Harvesting |

|---|---|---|

| Efficiency | High - harvests, threshes, and cleans grain simultaneously | Low - manual harvesting, separate threshing and cleaning required |

| Harvest Speed | Fast - covers large fields quickly | Slow - labor-intensive and time-consuming |

| Labor Requirement | Minimal - requires skilled operator | High - relies on manual laborers |

| Grain Loss | Low - calibrated for minimal loss | High - more losses due to manual handling |

| Cost | High initial investment and maintenance | Low initial cost, but higher labor expenses |

| Suitability | Large-scale grain crop farming | Small farms and regions lacking mechanization |

| Impact on Soil | Potential compaction due to machine weight | Minimal soil disturbance |

| Post-Harvest Processing | Integrated cleaning reduces processing time | Requires additional separate processing steps |

Introduction to Grain Harvesting Methods

Combine harvesters revolutionize grain crop harvesting by integrating reaping, threshing, and winnowing processes, significantly increasing efficiency compared to traditional manual methods. Traditional harvesting relies heavily on labor-intensive cutting and separate threshing, resulting in higher time consumption and grain loss. Mechanized harvesting with combine harvesters improves productivity, reduces post-harvest grain damage, and supports large-scale farming operations.

Overview of Combine Harvester Technology

Combine harvester technology integrates reaping, threshing, and winnowing into a single efficient operation, significantly increasing grain crop harvesting speed and reducing labor costs compared to traditional manual methods. Equipped with advanced sensors and GPS-guided automation, modern combine harvesters optimize grain yield and minimize losses during harvesting. This mechanized approach enhances productivity and supports large-scale farming, crucial for meeting global food demands.

Traditional Harvesting Techniques Explained

Traditional harvesting techniques for grain crops involve manual cutting using tools such as sickles or scythes, followed by threshing to separate grain from stalks and winnowing to remove chaff. These methods are labor-intensive and time-consuming, often resulting in lower efficiency and higher grain losses compared to mechanized harvesting. Despite this, traditional harvesting remains prevalent in many developing regions due to lower initial costs and limited access to modern machinery like combine harvesters.

Efficiency: Combine Harvester vs Traditional Methods

Combine harvesters significantly increase harvesting efficiency by integrating reaping, threshing, and winnowing in a single pass, reducing labor requirements and time consumption compared to traditional methods. Traditional harvesting relies heavily on manual labor or animal-driven tools, resulting in slower grain processing and higher post-harvest losses. The mechanized operation of combine harvesters improves grain yield quality and allows timely harvesting, which is critical for minimizing crop damage and maximizing productivity.

Labor Requirements and Costs Comparison

Combine harvesters significantly reduce labor requirements by automating reaping, threshing, and winnowing, allowing a single operator to manage large fields efficiently. Traditional harvesting demands intensive manual labor, often involving multiple workers for cutting, bundling, and processing grain, leading to higher labor costs and longer harvesting times. The initial investment and maintenance costs of combine harvesters are offset by reduced labor expenses and increased productivity, benefiting large-scale grain farming operations.

Grain Quality and Post-Harvest Losses

Combine harvesters significantly improve grain quality by minimizing mechanical damage and contamination compared to traditional harvesting methods, ensuring cleaner, more uniform grains. They reduce post-harvest losses through efficient threshing and cleaning processes, which decrease grain breakage and spillage common in manual harvesting. Advanced combine systems with real-time monitoring further optimize grain moisture and kernel integrity, enhancing overall yield value.

Environmental Impact of Harvesting Methods

Combine harvesters significantly reduce soil compaction and fuel consumption compared to traditional harvesting methods, lowering greenhouse gas emissions. The precise cutting and threshing mechanisms of combine harvesters minimize crop residue burn, thereby reducing air pollution. Conversely, traditional harvesting often involves manual labor or animal traction, leading to longer field exposure and higher organic waste decomposition, which can increase methane emissions.

Operational Challenges and Adaptability

Combine harvesters offer significant efficiency in grain crop harvesting by integrating reaping, threshing, and winnowing into a single operation, mitigating labor shortages and reducing harvesting time compared to traditional methods. However, operational challenges such as high initial investment, maintenance complexity, and sensitivity to field conditions can limit their adaptability in regions with irregular terrains or small-scale farms. Traditional harvesting methods, while labor-intensive and time-consuming, provide greater flexibility and adaptability in diverse agricultural settings, enabling farmers to manage varying crop types and field constraints without reliance on advanced machinery.

Economic Considerations for Farmers

Combine harvesters significantly reduce labor costs and harvesting time compared to traditional methods, enabling farmers to increase operational efficiency and profitability. High initial investment and maintenance expenses of combine harvesters can be offset by higher yields and reduced post-harvest losses associated with mechanized harvesting. Access to affordable financing and scale of farming operations critically influence the economic viability of adopting combine harvesters for grain crops.

Future Trends in Grain Harvesting Technologies

Combine harvesters are evolving with advanced sensor integration and automation to enhance precision and efficiency in grain crop harvesting. Innovations like GPS-guided machinery, real-time yield monitoring, and AI-driven crop analysis optimize harvesting operations, reducing waste and labor costs compared to traditional manual methods. Emerging trends emphasize sustainable practices and smart technology adoption to improve productivity and environmental impact in future grain harvesting systems.

Related Important Terms

Precision Harvesting

Combine harvesters equipped with advanced GPS technology and yield monitors enable precision harvesting by optimizing crop collection, reducing grain loss, and enhancing data-driven decision-making. Traditional harvesting methods lack real-time data analytics and often result in higher grain wastage and lower overall efficiency in grain crop production.

Multicrop Combine Efficiency

Multicrop combine harvesters significantly enhance efficiency by integrating threshing, separating, and cleaning processes into a single operation, reducing labor costs and time compared to traditional manual harvesting methods. Their advanced adaptability to various grain crops minimizes post-harvest losses and increases overall productivity on diverse agricultural terrains.

Grain Loss Assessment Technologies

Grain loss assessment technologies for combine harvesters utilize advanced sensors and imaging systems to accurately measure grain loss in real-time, significantly reducing post-harvest crop wastage compared to traditional harvesting methods that rely on manual, error-prone evaluation. These technologies integrate GPS mapping and machine learning algorithms to optimize harvester settings and improve overall grain yield efficiency in modern agricultural engineering practices.

Residue Management Systems

Combine harvesters utilize advanced residue management systems that efficiently distribute crop residues, enhancing soil fertility and reducing the need for additional soil amendments compared to traditional harvesting methods. Traditional grain harvesting often leaves uneven residue dispersal, leading to increased manual labor and potential soil degradation.

Header Adaptation Innovation

Header adaptation innovation in combine harvesters enhances efficiency and crop retention by automatically adjusting to varying crop heights and densities, reducing grain loss and minimizing soil compaction. Traditional harvesting methods lack this precise adaptability, often resulting in higher grain spillage and uneven crop cutting that decreases overall yield quality.

Real-Time Yield Mapping

Combine harvesters equipped with real-time yield mapping technology offer precise, field-specific data collection, enabling farmers to optimize grain crop management and increase harvest efficiency compared to traditional harvesting methods. This advanced system integrates GPS and sensor data to monitor yield variability, moisture content, and grain quality on-the-go, facilitating data-driven decisions and enhancing overall productivity.

Automated Threshing Adjustment

Automated threshing adjustment in combine harvesters enhances grain quality and reduces losses by precisely controlling the threshing drum speed and concave clearance based on real-time crop conditions. Traditional harvesting methods lack this adaptive technology, resulting in higher grain damage and inefficiencies during threshing.

Telematics in Harvest Operations

Telematics integration in combine harvesters enhances harvest operations by providing real-time data on machine performance, crop yield, and field conditions, which significantly improves efficiency compared to traditional grain harvesting methods. This technology enables precise monitoring and management of operations, reducing labor costs and minimizing crop losses while optimizing resource use throughout the harvesting process.

Sustainable Combine Fueling

Combine harvesters powered by sustainable fuels such as biodiesel and renewable diesel significantly reduce greenhouse gas emissions and soil compaction compared to traditional manual harvesting methods, enhancing environmental sustainability in grain crop production. The adoption of fuel-efficient engine technologies in combines promotes lower fossil fuel dependency and supports long-term soil health and crop yield stability.

Labor-Displacement Metrics

Combine harvesters significantly reduce labor requirements by mechanizing cutting, threshing, and cleaning processes, enabling a single operator to replace dozens of manual laborers in grain crop harvesting. Traditional harvesting demands extensive manual labor input, often involving multiple workers per acre, which leads to higher labor-displacement rates and lower overall harvesting efficiency.

Combine harvester vs traditional harvesting for grain crops Infographic

agridif.com

agridif.com