Grading involves classifying agricultural products based on specific quality standards such as size, color, and texture, ensuring uniformity for market requirements. Sorting separates products by physical characteristics like size or weight but lacks formal quality criteria, serving primarily to organize goods for packaging or processing. Effective marketing strategies utilize both grading and sorting to enhance product appeal and meet consumer expectations in competitive agricultural markets.

Table of Comparison

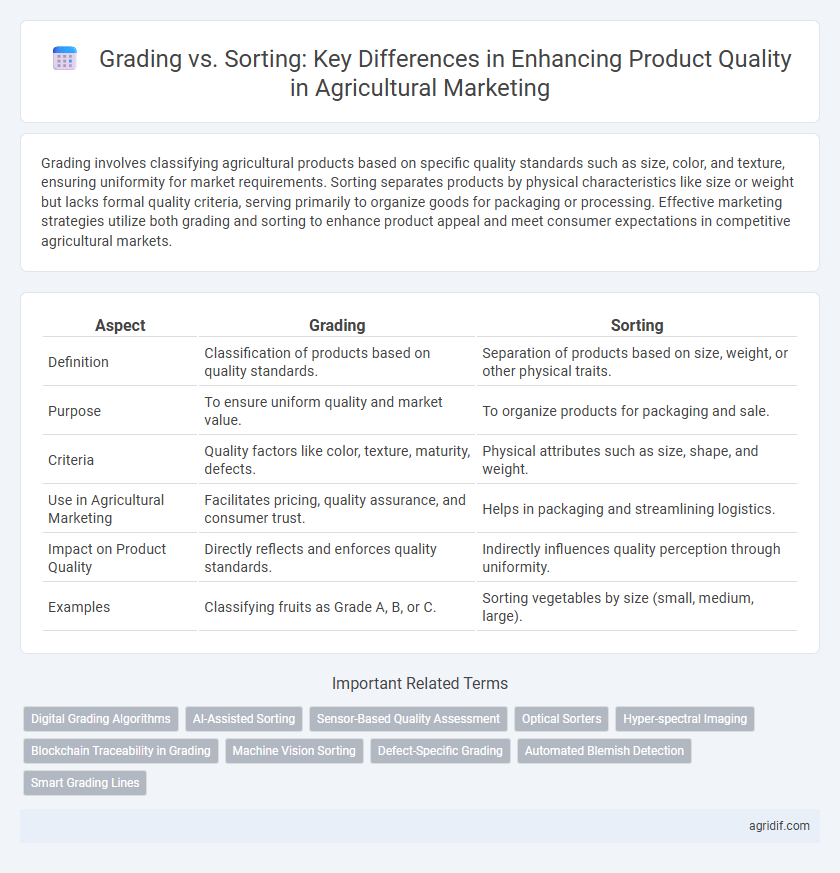

| Aspect | Grading | Sorting |

|---|---|---|

| Definition | Classification of products based on quality standards. | Separation of products based on size, weight, or other physical traits. |

| Purpose | To ensure uniform quality and market value. | To organize products for packaging and sale. |

| Criteria | Quality factors like color, texture, maturity, defects. | Physical attributes such as size, shape, and weight. |

| Use in Agricultural Marketing | Facilitates pricing, quality assurance, and consumer trust. | Helps in packaging and streamlining logistics. |

| Impact on Product Quality | Directly reflects and enforces quality standards. | Indirectly influences quality perception through uniformity. |

| Examples | Classifying fruits as Grade A, B, or C. | Sorting vegetables by size (small, medium, large). |

Understanding Grading and Sorting in Agricultural Marketing

Grading in agricultural marketing involves categorizing products based on specific quality standards such as size, weight, color, and maturity, which helps in pricing and market positioning. Sorting, on the other hand, refers to separating products according to physical characteristics to ensure uniformity within each category but does not necessarily assign a quality grade. Understanding the distinction between grading and sorting is crucial for farmers and marketers to meet consumer expectations and comply with regulatory requirements, ultimately enhancing market efficiency and product value.

Defining Grading: Standards and Classifications

Grading in agricultural marketing involves categorizing products based on established standards and classifications that assess quality parameters such as size, color, texture, and maturity. These standards are developed by regulatory bodies or industry organizations to ensure uniformity, facilitate fair pricing, and meet consumer expectations. Grading provides a systematic approach to quality control, distinguishing it from sorting, which primarily separates products based on physical appearance without standardized criteria.

Sorting: Methods and Techniques in Agriculture

Sorting in agricultural marketing involves categorizing products based on specific characteristics such as size, color, shape, and ripeness using advanced techniques like optical sorting, manual culling, and mechanical separators. These methods enhance the precision of grading by eliminating defective or substandard produce, thereby improving overall product quality and market value. Implementing efficient sorting technologies boosts supply chain efficiency and consumer satisfaction by ensuring consistent quality and reducing post-harvest losses.

Key Differences Between Grading and Sorting

Grading categorizes agricultural products based on predetermined quality standards such as size, color, and texture, ensuring uniformity for market standards, while sorting separates products according to physical characteristics like size or weight without necessarily meeting quality benchmarks. Grading involves official inspection and certification to meet regulatory requirements, whereas sorting is typically a preliminary step aimed at organizing products for processing or packaging. The key difference lies in grading's emphasis on quality assurance and standardization, contrasting with sorting's focus on basic separation and handling efficiency.

The Role of Grading in Ensuring Product Quality

Grading plays a critical role in ensuring product quality by categorizing agricultural commodities based on predefined standards such as size, color, texture, and ripeness. It provides consumers and buyers with reliable information that guarantees consistency, enhances marketability, and supports fair pricing. Efficient grading reduces post-harvest losses and improves supply chain management by maintaining uniformity and quality assurance across batches.

How Sorting Enhances Market Value

Sorting agricultural products by size, color, and ripeness directly enhances market value by meeting specific buyer preferences and reducing product variability. This targeted classification enables farmers and marketers to position premium quality goods in higher-value market segments, increasing profitability. Efficient sorting minimizes post-harvest losses and improves supply chain consistency, driving consumer satisfaction and stronger demand.

Grading and Sorting: Impact on Supply Chain Efficiency

Grading categorizes agricultural products based on specific quality standards such as size, color, and maturity, ensuring uniformity that facilitates pricing and market acceptance. Sorting separates products according to physical attributes, aiding in the removal of substandard items and reducing variability. Together, effective grading and sorting improve supply chain efficiency by optimizing inventory management, minimizing losses during transportation, and enhancing consumer satisfaction through consistent product quality.

Technology and Innovation in Grading vs Sorting

Advanced technologies in agricultural marketing have revolutionized grading and sorting processes, enhancing product quality assessment through automation and precision sensors. Grading leverages machine learning algorithms and hyperspectral imaging to classify products based on quality standards, ensuring consistency and market compliance. Sorting utilizes robotic systems and real-time data analytics to separate produce by size, color, and defect detection, optimizing supply chain efficiency and reducing post-harvest losses.

Challenges in Implementing Grading and Sorting Systems

Implementing grading and sorting systems in agricultural marketing faces significant challenges such as high initial costs for advanced equipment and the need for skilled labor to accurately classify products based on quality attributes like size, color, and ripeness. Variability in crop characteristics and environmental factors complicate the standardization process, causing inconsistencies in product categorization. Limited infrastructure and lack of farmer awareness further hinder the adoption of efficient grading and sorting practices, impacting market access and pricing.

Future Trends in Product Quality Management

Grading involves categorizing agricultural products based on predetermined quality standards such as size, weight, and appearance, while sorting separates products according to specific criteria like color or ripeness to meet consumer preferences. Future trends in product quality management are leaning towards integrating advanced technologies such as AI-powered imaging and blockchain to ensure precise grading, transparency, and traceability throughout the supply chain. These innovations enable real-time quality assessment and enhance market trust by minimizing discrepancies between labeled grades and actual product conditions.

Related Important Terms

Digital Grading Algorithms

Digital grading algorithms enhance agricultural marketing by providing precise, consistent assessment of product quality based on quantifiable attributes like size, color, and texture, optimizing grading over traditional sorting methods. These algorithms improve market transparency and buyer confidence by reducing subjective human error and enabling scalable, rapid evaluation across large volumes of produce.

AI-Assisted Sorting

AI-assisted sorting in agricultural marketing enhances product quality by using advanced machine learning algorithms to classify produce based on size, color, and ripeness, ensuring consistent quality standards. Unlike traditional grading, which relies on human inspection and predefined criteria, AI sorting offers real-time analysis and higher accuracy, reducing waste and improving market segmentation.

Sensor-Based Quality Assessment

Sensor-based quality assessment in agricultural marketing enhances grading by providing objective, precise measurements of product attributes such as color, size, and firmness, enabling consistent classification standards. Sorting, relying on sensor data, efficiently separates produce into distinct quality categories, optimizing supply chain decisions and reducing waste.

Optical Sorters

Optical sorters enhance agricultural marketing by using advanced imaging technology to accurately grade products based on color, shape, and size, improving quality consistency. Unlike traditional sorting, grading classifies products into defined quality categories that meet market standards, enabling better pricing strategies and consumer trust.

Hyper-spectral Imaging

Hyper-spectral imaging enhances agricultural marketing by providing precise grading based on detailed spectral data, enabling accurate assessment of product quality attributes such as ripeness, moisture content, and defects. Unlike traditional sorting, which categorizes products by size or appearance, hyper-spectral imaging offers a non-destructive, data-driven approach for uniform grading, increasing market value and consumer trust.

Blockchain Traceability in Grading

Grading classifies agricultural products based on predefined quality standards, while sorting separates items by physical attributes such as size and color; blockchain traceability enhances grading accuracy by providing immutable, transparent records of product quality from farm to market. This integration ensures trust and accountability in supply chains, enabling stakeholders to verify grading authenticity and streamline quality assurance processes.

Machine Vision Sorting

Machine vision sorting enhances agricultural marketing by providing precise, automated product quality assessment through advanced imaging technology, enabling consistent grading based on size, color, and defects. Grading categorizes products into quality classes, while sorting separates items based on specific attributes, with machine vision improving accuracy and efficiency in both processes.

Defect-Specific Grading

Defect-specific grading in agricultural marketing categorizes products based on the type and severity of defects, ensuring consistent quality standards that directly impact price and marketability. Unlike sorting, which groups products by general size or appearance, grading provides a detailed assessment that enables targeted quality control and enhances consumer trust.

Automated Blemish Detection

Automated blemish detection enhances agricultural marketing by enabling precise grading of produce based on quality attributes such as size, color, and surface defects, surpassing the traditional sorting methods that often rely on manual inspection. Advanced imaging technologies and machine learning algorithms facilitate consistent, objective grading, improving product classification, reducing market variability, and boosting consumer confidence.

Smart Grading Lines

Smart grading lines in agricultural marketing enhance product quality by precisely categorizing produce based on size, weight, and external defects, ensuring consistency and meeting market standards. Unlike traditional sorting, these lines use advanced sensors and AI technology to improve accuracy and efficiency, reducing waste and increasing consumer trust.

Grading vs Sorting for product quality Infographic

agridif.com

agridif.com