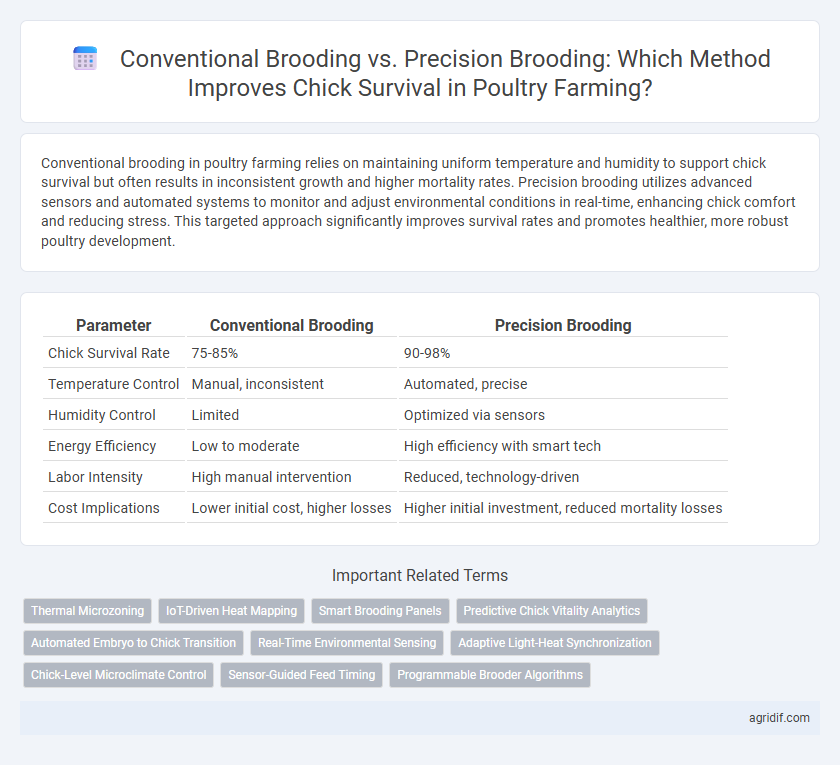

Conventional brooding in poultry farming relies on maintaining uniform temperature and humidity to support chick survival but often results in inconsistent growth and higher mortality rates. Precision brooding utilizes advanced sensors and automated systems to monitor and adjust environmental conditions in real-time, enhancing chick comfort and reducing stress. This targeted approach significantly improves survival rates and promotes healthier, more robust poultry development.

Table of Comparison

| Parameter | Conventional Brooding | Precision Brooding |

|---|---|---|

| Chick Survival Rate | 75-85% | 90-98% |

| Temperature Control | Manual, inconsistent | Automated, precise |

| Humidity Control | Limited | Optimized via sensors |

| Energy Efficiency | Low to moderate | High efficiency with smart tech |

| Labor Intensity | High manual intervention | Reduced, technology-driven |

| Cost Implications | Lower initial cost, higher losses | Higher initial investment, reduced mortality losses |

Understanding Brooding: Conventional vs Precision Approaches

Conventional brooding relies on uniform heat and manual monitoring, often leading to inconsistent temperature control that can stress chicks and reduce survival rates. Precision brooding uses advanced sensors and automated systems to maintain optimal microclimate conditions, enhancing chick comfort and significantly improving survival outcomes. Data-driven temperature adjustments in precision brooding reduce energy waste and promote healthier growth environments compared to traditional methods.

Key Differences in Brooding Methods

Conventional brooding relies on uniform temperature and manual monitoring, often leading to inconsistent environmental conditions that can stress chicks and reduce survival rates. Precision brooding uses real-time data analytics and automated control systems to maintain optimal temperature, humidity, and ventilation tailored to chick behavior and growth stages. This targeted approach enhances chick comfort, improves immune function, and significantly increases survival rates compared to traditional methods.

Technology in Precision Brooding

Precision brooding utilizes advanced sensor technology and automated climate control to optimize temperature, humidity, and ventilation tailored to chick needs, significantly improving survival rates. Real-time data analytics enable precise environmental adjustments, reducing stress and promoting uniform growth compared to conventional brooding methods. Integration of IoT devices and machine learning algorithms enhances monitoring accuracy, leading to healthier poultry flocks and increased operational efficiency.

Chick Survival Rates: Conventional vs Precision

Precision brooding significantly enhances chick survival rates by maintaining optimal temperature, humidity, and ventilation tailored to the chicks' developmental stages, reducing stress and mortality compared to conventional brooding methods. Conventional brooding often results in uneven environmental conditions, leading to higher instances of temperature-related stress, dehydration, and increased susceptibility to disease. Studies show that precision brooding can improve chick survival rates by up to 15-20%, supporting healthier flock development and better overall productivity.

Environmental Control in Brooding Practices

Environmental control in brooding practices significantly impacts chick survival, with precision brooding offering superior regulation of temperature, humidity, and ventilation compared to conventional brooding. Precision brooding systems utilize sensors and automated climate controls to maintain optimal microclimates, reducing stress and mortality rates in poultry flocks. Conventional brooding often relies on manual adjustments, resulting in less consistent environmental conditions and higher risks of temperature fluctuations detrimental to chick health.

Cost Implications of Each Brooding Method

Conventional brooding methods in poultry farming often incur higher operational costs due to less efficient temperature control and increased energy consumption, leading to potential higher mortality rates in chicks. Precision brooding utilizes automated climate control systems and real-time data analytics to optimize environmental conditions, significantly reducing energy usage and improving chick survival rates, which lowers overall costs. Investment in precision brooding technology may have higher upfront expenses but results in long-term cost savings through enhanced productivity and reduced mortality.

Labor Requirements in Conventional and Precision Brooding

Conventional brooding in poultry farming demands intensive manual labor for monitoring temperature, feeding, and chick care, often requiring numerous workers to ensure optimal chick survival rates. Precision brooding leverages automated systems and sensors to regulate environmental conditions and feeding schedules, significantly reducing the need for constant human intervention and lowering labor costs. This technological advancement enhances operational efficiency while maintaining or improving chick survival outcomes through precise control and timely adjustments.

Impact on Chick Health and Early Growth

Conventional brooding relies on uniform temperature and manual monitoring, often leading to inconsistent chick health and varied early growth rates. Precision brooding uses advanced sensors and automated environmental controls to optimize temperature, humidity, and ventilation specific to chick needs, significantly improving chick survival and promoting uniform early growth. Studies show precision brooding reduces stress and respiratory issues, enhancing overall flock vitality during critical developmental stages.

Decision Factors for Choosing a Brooding System

Decision factors for choosing between conventional and precision brooding systems in poultry farming hinge on chick survival rates, energy efficiency, and labor intensity. Precision brooding leverages automated climate control and real-time monitoring to optimize temperature and humidity, leading to improved chick health and reduced mortality. Conventional brooding demands higher manual oversight and energy use, often resulting in inconsistent environmental conditions and variable survival outcomes.

Future Trends in Poultry Brooding Strategies

Future trends in poultry brooding emphasize precision brooding techniques that utilize advanced sensors and automated climate control systems to optimize chick survival rates. Conventional brooding methods, relying on fixed heat sources and manual monitoring, are increasingly supplemented by data-driven solutions that adjust environmental conditions in real time for improved welfare. Integration of IoT technology and AI analytics in brooding promises enhanced precision, energy efficiency, and significant reductions in mortality across commercial poultry operations.

Related Important Terms

Thermal Microzoning

Thermal microzoning in precision brooding creates tailored temperature gradients that improve chick survival by mimicking natural warmth distribution, unlike conventional brooding which applies uniform heat often leading to temperature stress and higher mortality. This targeted thermal environment enhances metabolic efficiency and immune response in chicks, promoting healthier growth and reducing early-stage losses in poultry farming.

IoT-Driven Heat Mapping

IoT-driven heat mapping in precision brooding enables real-time monitoring of temperature variations, ensuring optimal thermal conditions that significantly improve chick survival rates compared to conventional brooding methods. By accurately identifying and addressing cold or hot spots within the brooding area, poultry farmers can reduce mortality, enhance growth performance, and optimize energy consumption.

Smart Brooding Panels

Smart brooding panels in precision brooding optimize temperature, humidity, and ventilation, significantly enhancing chick survival rates compared to conventional brooding, which often relies on uniform settings and manual adjustments. These intelligent systems continuously monitor environmental conditions, ensuring optimal thermal comfort and reducing stress, disease, and mortality in poultry farms.

Predictive Chick Vitality Analytics

Precision brooding leverages predictive chick vitality analytics to monitor environmental variables and chick behavior in real-time, significantly improving survival rates compared to conventional brooding methods. By utilizing data-driven insights on temperature, humidity, and chick activity, precision brooding enables early interventions that reduce mortality and enhance overall flock health.

Automated Embryo to Chick Transition

Conventional brooding relies on manual temperature regulation and monitoring, often leading to inconsistent environmental conditions that can affect chick survival rates. Precision brooding utilizes automated systems to optimize embryo-to-chick transition by maintaining stable temperature, humidity, and ventilation, significantly improving chick health and reducing mortality.

Real-Time Environmental Sensing

Real-time environmental sensing in precision brooding enables continuous monitoring of temperature, humidity, and ventilation, optimizing conditions to significantly improve chick survival rates compared to conventional brooding methods that rely on static settings and manual adjustments. This technology reduces heat stress and respiratory issues, promoting healthier development and reducing mortality in poultry farming operations.

Adaptive Light-Heat Synchronization

Adaptive Light-Heat Synchronization in precision brooding enhances chick survival by closely mimicking natural environmental cues, leading to improved thermoregulation and reduced stress compared to conventional brooding methods. This targeted control of lighting and temperature cycles accelerates early growth rates and strengthens immune responses, resulting in higher overall flock vitality.

Chick-Level Microclimate Control

Precision brooding enhances chick survival by maintaining an individualized microclimate, optimizing temperature and humidity directly at the chick level, unlike conventional brooding which relies on broader environmental controls. This targeted approach reduces stress and health issues, significantly improving early growth rates and overall flock uniformity.

Sensor-Guided Feed Timing

Sensor-guided feed timing in precision brooding significantly enhances chick survival rates by providing tailored nutrition aligned with real-time behavioral and environmental data, reducing stress and promoting steady growth. Conventional brooding relies on fixed feeding schedules that may not match individual chick needs, often leading to uneven development and higher mortality.

Programmable Brooder Algorithms

Programmable brooder algorithms in precision brooding optimize temperature, humidity, and ventilation parameters tailored to chick behavior and developmental stages, significantly enhancing chick survival rates compared to conventional brooding methods. These adaptive systems reduce mortality by maintaining ideal microclimates, minimizing stress and energy waste, thus promoting healthier growth and improved flock uniformity.

Conventional Brooding vs Precision Brooding for Chick Survival Infographic

agridif.com

agridif.com