Floor feeding promotes natural foraging behaviors and reduces stress among poultry, enhancing overall well-being. Chain feeding ensures consistent feed distribution and minimizes wastage by evenly delivering food across the flock. Choosing between floor and chain feeding depends on flock size, management style, and nutritional goals for optimal poultry nutrition delivery.

Table of Comparison

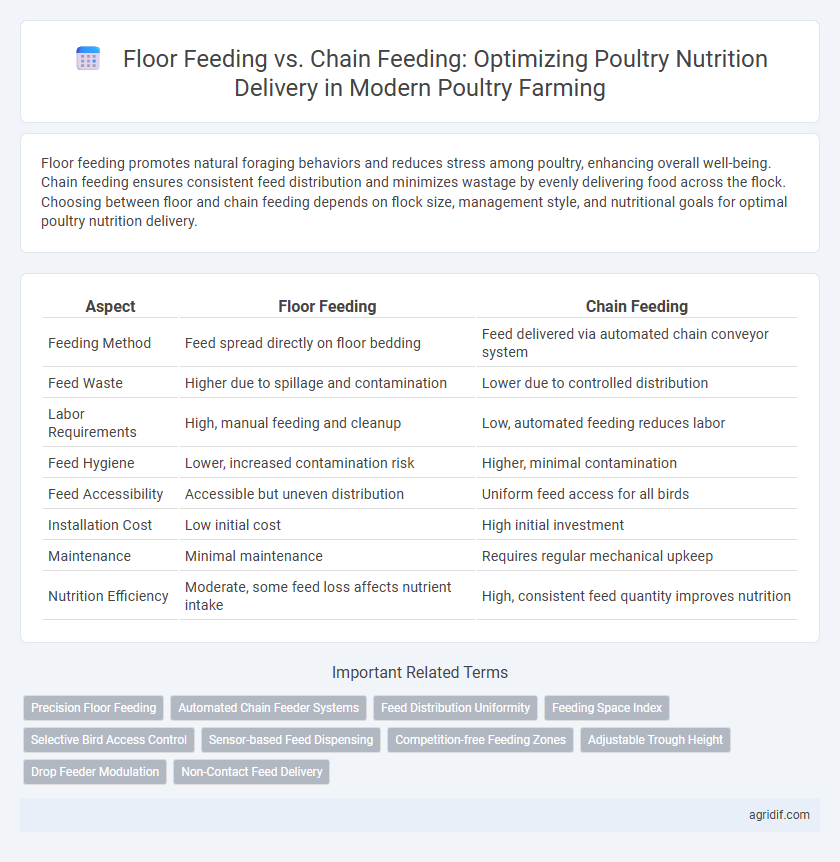

| Aspect | Floor Feeding | Chain Feeding |

|---|---|---|

| Feeding Method | Feed spread directly on floor bedding | Feed delivered via automated chain conveyor system |

| Feed Waste | Higher due to spillage and contamination | Lower due to controlled distribution |

| Labor Requirements | High, manual feeding and cleanup | Low, automated feeding reduces labor |

| Feed Hygiene | Lower, increased contamination risk | Higher, minimal contamination |

| Feed Accessibility | Accessible but uneven distribution | Uniform feed access for all birds |

| Installation Cost | Low initial cost | High initial investment |

| Maintenance | Minimal maintenance | Requires regular mechanical upkeep |

| Nutrition Efficiency | Moderate, some feed loss affects nutrient intake | High, consistent feed quantity improves nutrition |

Introduction to Poultry Nutrition Delivery Systems

Floor feeding and chain feeding are two primary poultry nutrition delivery systems designed to optimize feed accessibility and reduce wastage in commercial poultry farms. Floor feeding involves spreading feed evenly on the poultry house floor, promoting natural foraging behavior but increasing the risk of contamination and uneven nutrient intake. Chain feeding systems use hanging feeders that automatically dispense controlled amounts of feed, enhancing feed efficiency, minimizing waste, and supporting uniform growth rates across poultry flocks.

Overview of Floor Feeding in Poultry Farming

Floor feeding in poultry farming involves directly distributing feed onto the floor of the poultry house, allowing birds to freely access and consume the feed throughout the day. This method supports natural foraging behavior, reduces feed wastage through controlled portions, and is cost-effective for small to medium-sized operations. However, floor feeding requires diligent management to maintain feed hygiene and minimize contamination risks from droppings and moisture.

Understanding Chain Feeding Mechanisms

Chain feeding mechanisms in poultry nutrition delivery utilize automated conveyor systems to distribute feed evenly across multiple cages or floor sections, enhancing feed accessibility and reducing wastage. These systems ensure precise portion control, promoting consistent growth rates and minimizing nutritional imbalances in poultry flocks. Implementation of chain feeders also reduces labor costs and improves biosecurity by limiting human contact with the birds during feeding times.

Nutrient Distribution Efficiency: Floor vs Chain Feeding

Chain feeding systems ensure consistent nutrient distribution by delivering feed directly to each bird, minimizing waste and uneven consumption common in floor feeding. Floor feeding often leads to variable nutrient intake due to feed spillage and competition among poultry, reducing overall feed efficiency. Optimized chain feeder designs improve uniformity in diet delivery, positively impacting growth rates and feed conversion ratios in poultry farming.

Impact on Feed Wastage and Cost Effectiveness

Floor feeding in poultry allows birds to peck freely, but often leads to higher feed wastage due to spillage and contamination, increasing overall feeding costs. Chain feeding systems provide controlled distribution of feed directly to the birds, significantly reducing wastage and enhancing cost-effectiveness by optimizing feed utilization. Efficient feed delivery through chain feeders directly improves poultry nutrition management by ensuring consistent access and minimizing resource loss.

Influences on Bird Health and Performance

Floor feeding allows birds unrestricted access to feed, promoting natural foraging behavior that can enhance digestive health and reduce stress-related issues. Chain feeding provides uniform feed distribution, minimizing feed wastage and ensuring consistent nutrient intake, which supports steady growth and optimal weight gain. Research indicates that chain feeding systems often result in improved feed conversion ratios and lower incidence of gastrointestinal problems compared to floor feeding methods.

Labor Requirements: Manual vs Automated Systems

Floor feeding demands intense manual labor for spreading feed evenly and monitoring consumption, increasing workforce needs and operational time. Chain feeding systems automate feed distribution along fixed tracks, significantly reducing human intervention and labor costs while ensuring consistent nutrition delivery. The choice between these methods impacts efficiency, labor management, and overall productivity in poultry farming operations.

Biosecurity and Cleanliness Concerns

Floor feeding in poultry farming poses higher biosecurity risks due to increased exposure to contaminants from litter, feces, and pests, leading to potential disease outbreaks. Chain feeding systems offer improved cleanliness by reducing feed spillage and minimizing contact with droppings, thereby enhancing nutrient delivery efficiency and maintaining healthier flocks. Implementing chain feeders supports stricter sanitation protocols, crucial for controlling pathogens like Salmonella and avian influenza within poultry houses.

Scalability for Small and Large Poultry Operations

Floor feeding offers flexibility and low initial costs, making it ideal for small poultry operations with limited budget and space, while chain feeding systems provide consistent feed delivery and better feed conversion rates, benefiting large-scale commercial farms. Scalability in floor feeding is limited by manual labor intensity and feed wastage, whereas chain feeding can be automated and expanded to accommodate thousands of birds efficiently. Choosing the right feeding system hinges on operational scale, with chain feeding offering superior scalability for high-density poultry production.

Choosing the Right System for Optimal Results

Floor feeding offers birds natural foraging behavior and reduced feed wastage, making it suitable for free-range or backyard poultry systems. Chain feeding provides consistent, controlled feed distribution, ideal for large-scale commercial operations requiring precise nutrition management. Selecting the right feeding system depends on flock size, housing type, and management goals to maximize feed efficiency and bird health.

Related Important Terms

Precision Floor Feeding

Precision Floor Feeding in poultry nutrition delivery enhances feed efficiency by distributing nutrients uniformly across the floor, ensuring consistent intake among birds and reducing feed wastage compared to traditional chain feeding systems. This method supports optimal growth rates and improves flock health by targeting dietary needs accurately at varying bird ages and sizes.

Automated Chain Feeder Systems

Automated chain feeder systems optimize poultry nutrition delivery by ensuring consistent feed distribution along elevated troughs, reducing feed wastage and contamination compared to floor feeding methods. These systems enhance feed efficiency, promote uniform growth, and facilitate precise control over feeding schedules in commercial poultry operations.

Feed Distribution Uniformity

Floor feeding often results in uneven feed distribution due to bird competition and feed spillage, leading to inconsistent nutrient intake among poultry. Chain feeding systems provide more uniform feed delivery by ensuring continuous, controlled distribution along the feeding line, optimizing poultry nutrition and growth performance.

Feeding Space Index

Floor feeding offers a flexible Feeding Space Index by allowing birds to move freely and access food at their own pace, which can reduce competition and stress among poultry. Chain feeding systems provide a controlled Feeding Space Index with evenly distributed feed, ensuring consistent nutrition delivery and minimizing waste.

Selective Bird Access Control

Floor feeding allows birds to access feed freely but increases feed wastage and limits control over individual bird intake, whereas chain feeding systems deliver feed at fixed stations, enhancing selective bird access control and reducing competition among poultry. Optimized selective access in chain feeding promotes uniform nutrition distribution, improves growth rates, and minimizes feed loss compared to traditional floor feeding methods.

Sensor-based Feed Dispensing

Sensor-based feed dispensing enhances precision in both floor feeding and chain feeding systems by monitoring poultry behavior and adjusting feed delivery in real-time, reducing waste and improving nutrient uptake. Integrating IoT sensors with automated feeders ensures optimal feed distribution tailored to flock size and activity, boosting overall poultry health and growth efficiency.

Competition-free Feeding Zones

Floor feeding creates competition-free feeding zones by allowing multiple birds simultaneous access to scattered feed, reducing aggression and ensuring uniform nutrient intake essential for optimal poultry growth. Chain feeding systems, while efficient in feed distribution, often lead to hierarchical feeding access that can cause dominant birds to monopolize feed, limiting nutrition delivery to subordinate poultry.

Adjustable Trough Height

Adjustable trough height in poultry feeding systems enhances bird comfort and access, promoting uniform feed intake and reducing wastage in both floor feeding and chain feeding methods. Optimizing trough height according to bird age and size improves nutrition delivery efficiency, supporting better growth performance and overall flock health.

Drop Feeder Modulation

Drop feeder modulation enhances precision in poultry nutrition delivery by optimizing feed distribution timing and quantity, reducing waste compared to traditional floor feeding systems. Chain feeding offers uniform access for large flocks, but drop feeders enable targeted nutrient supply, improving feed conversion ratios and overall flock health.

Non-Contact Feed Delivery

Floor feeding allows poultry to access feed freely, promoting natural pecking behavior and reducing stress, which supports improved digestion and nutrient absorption. Chain feeding delivers feed efficiently along a continuous line, minimizing feed wastage and contamination by reducing physical contact between birds and feed, enhancing biosecurity in poultry nutrition management.

Floor Feeding vs Chain Feeding for Poultry Nutrition Delivery Infographic

agridif.com

agridif.com