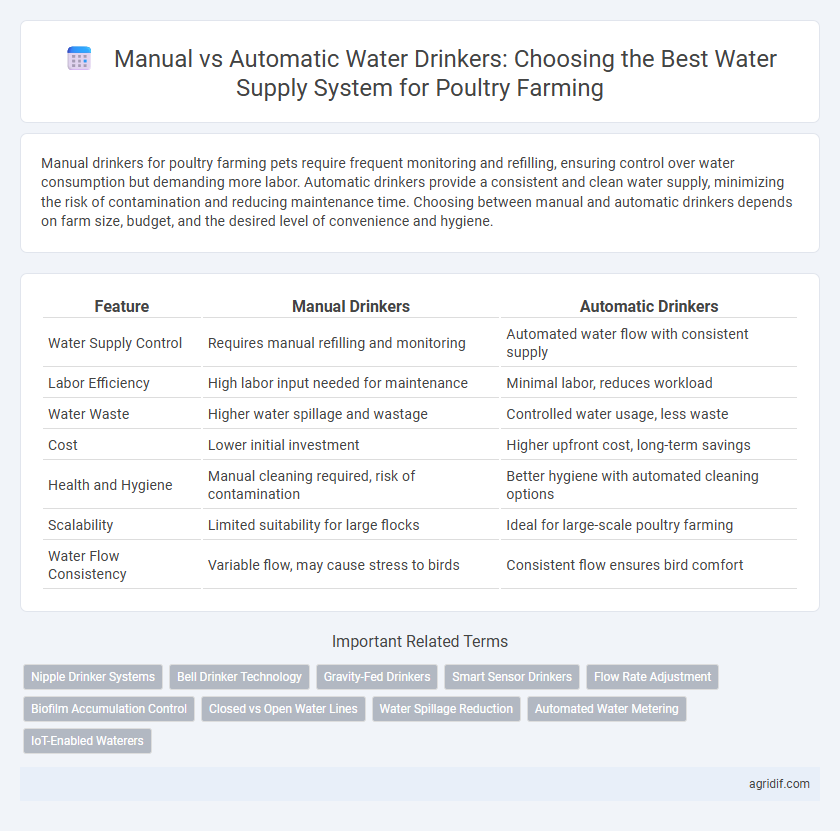

Manual drinkers for poultry farming pets require frequent monitoring and refilling, ensuring control over water consumption but demanding more labor. Automatic drinkers provide a consistent and clean water supply, minimizing the risk of contamination and reducing maintenance time. Choosing between manual and automatic drinkers depends on farm size, budget, and the desired level of convenience and hygiene.

Table of Comparison

| Feature | Manual Drinkers | Automatic Drinkers |

|---|---|---|

| Water Supply Control | Requires manual refilling and monitoring | Automated water flow with consistent supply |

| Labor Efficiency | High labor input needed for maintenance | Minimal labor, reduces workload |

| Water Waste | Higher water spillage and wastage | Controlled water usage, less waste |

| Cost | Lower initial investment | Higher upfront cost, long-term savings |

| Health and Hygiene | Manual cleaning required, risk of contamination | Better hygiene with automated cleaning options |

| Scalability | Limited suitability for large flocks | Ideal for large-scale poultry farming |

| Water Flow Consistency | Variable flow, may cause stress to birds | Consistent flow ensures bird comfort |

Introduction to Poultry Watering Systems

Poultry watering systems include manual and automatic drinkers designed to provide clean, accessible water to birds, crucial for maintaining optimal health and productivity. Manual drinkers require regular refilling and monitoring, making them cost-effective but labor-intensive, while automatic drinkers use sensors or timers to ensure continuous water availability, enhancing efficiency in large-scale operations. Selecting the appropriate system depends on farm size, labor availability, and water consumption patterns to optimize poultry welfare and resource management.

Understanding Manual Drinkers

Manual drinkers in poultry farming require regular human intervention to ensure a consistent water supply, relying on workers to refill and monitor water levels. These systems are often simpler and cost-effective for small-scale operations but may lead to inconsistent hydration if not managed properly. Understanding the labor-intensive nature and potential risks of manual drinkers is crucial for optimizing poultry health and overall farm efficiency.

Overview of Automatic Drinkers

Automatic drinkers in poultry farming enhance water supply efficiency by delivering consistent and clean water directly to birds, reducing labor and waste. These systems often incorporate sensors or pressure mechanisms that activate water flow only when pecked or touched, ensuring minimal spillage and contamination. Installation of automatic drinkers supports improved flock health and minimizes waterborne diseases compared to manual systems.

Installation and Setup Requirements

Manual drinkers for poultry farming require simple installation with straightforward water connection and frequent adjustment to maintain flow. Automatic drinkers demand more complex setup, including pressure regulation, secure plumbing, and positioning to ensure consistent water delivery and minimize contamination. Proper installation of automatic systems enhances efficiency and reduces labor compared to manual drinkers.

Maintenance and Cleaning Needs

Manual drinkers in poultry farming require frequent cleaning and regular manual inspection to prevent contamination and ensure consistent water quality. Automatic drinkers reduce labor by providing a continuous water supply and often feature self-cleaning mechanisms or easy disassembly for maintenance. Choosing automatic systems can enhance hygiene and minimize downtime, but periodic thorough cleaning remains essential to avoid biofilm buildup and bacterial growth.

Water Quality and Hygiene Impacts

Automatic drinkers in poultry farming maintain consistent water flow and reduce contamination risks by minimizing exposure to dust and droppings, thereby enhancing water quality and hygiene. Manual drinkers often require frequent cleaning and monitoring to prevent bacterial growth and water stagnation, which can compromise flock health. Optimizing water supply systems with automatic drinkers supports better disease control and improves overall poultry welfare.

Cost Comparison: Initial Investment and Long-term Expenses

Manual drinkers for poultry farming involve lower initial investment costs due to their simple design and minimal installation requirements, making them suitable for small-scale operations. Automatic drinkers require higher upfront expenses for equipment and setup but reduce long-term labor costs and water wastage through efficient delivery systems. Over time, automatic drinkers offer better cost-efficiency by minimizing maintenance and improving water management compared to manual systems.

Labor and Time Efficiency

Manual drinkers in poultry farming demand significant labor input and time for regular refilling and cleaning, impacting overall operational efficiency. Automatic drinkers optimize labor by providing a continuous water supply with minimal human intervention, reducing time spent on maintenance and increasing productivity. Transitioning to automatic systems enhances time efficiency and allows workers to focus on other critical farm management tasks.

Effects on Bird Health and Productivity

Manual drinkers in poultry farming require frequent refilling and cleaning, which can lead to inconsistent water availability and increased risk of contamination, negatively impacting bird health and growth rates. Automatic drinkers provide a constant, clean water supply, reducing stress and promoting optimal hydration, thereby enhancing feed conversion efficiency and overall productivity. Consistent access to clean water with automatic systems helps prevent diseases and supports better weight gain, translating to higher farm profitability.

Choosing the Right Drinker for Your Poultry Farm

Selecting the right drinker for your poultry farm significantly influences water efficiency and bird health. Manual drinkers require regular refilling and maintenance, making them suitable for small-scale setups, while automatic drinkers provide consistent water supply, reduce labor, and minimize contamination risks in large commercial operations. Assessing flock size, farm infrastructure, and budget helps determine whether manual or automatic water drinkers best optimize poultry hydration and productivity.

Related Important Terms

Nipple Drinker Systems

Nipple drinker systems in poultry farming provide precise water delivery, reducing spillage and contamination compared to manual drinkers, which require frequent monitoring and manual refilling. Automatic nipple drinkers enhance biosecurity and water efficiency by ensuring continuous, controlled hydration tailored to the birds' consumption patterns.

Bell Drinker Technology

Bell drinker technology in poultry farming offers a reliable automatic water supply system that minimizes water wastage and contamination compared to manual drinkers. Its design ensures consistent water flow and easy maintenance, promoting optimal hydration and health in poultry flocks.

Gravity-Fed Drinkers

Gravity-fed drinkers in poultry farming offer a cost-effective and low-maintenance water supply solution, relying on gravity to provide a constant flow without the need for electricity or pumps. These manual drinkers help reduce water wastage and ensure birds have continuous access to clean water, making them ideal for small to medium-sized operations.

Smart Sensor Drinkers

Smart sensor drinkers in poultry farming offer precise water supply management by automatically adjusting flow based on bird activity, reducing water waste and contamination risk. Manual drinkers lack these efficiencies, often leading to inconsistent hydration and higher maintenance efforts.

Flow Rate Adjustment

Manual drinkers allow precise flow rate adjustment through simple valve manipulation, enabling farmers to control water supply based on flock size and environmental conditions. Automatic drinkers offer consistent flow rates with minimal intervention, utilizing pressure regulators and sensors to maintain optimal hydration levels for poultry.

Biofilm Accumulation Control

Automatic drinkers in poultry farming offer superior biofilm accumulation control by providing consistent water flow and minimizing stagnant areas where bacteria thrive, unlike manual drinkers that often retain residual water promoting microbial growth. The continuous water movement in automatic systems reduces biofilm formation, enhancing water hygiene and improving flock health.

Closed vs Open Water Lines

Closed water lines in automatic drinkers maintain hygiene by preventing contamination and reducing water waste, making them ideal for large-scale poultry farms focused on health and efficiency. Manual open water lines, commonly used with traditional drinkers, require frequent monitoring and cleaning to avoid bacterial growth and water spillage, which can increase labor costs and affect bird health.

Water Spillage Reduction

Automatic drinkers in poultry farming significantly reduce water spillage by delivering consistent water flow tailored to bird size and consumption patterns, resulting in drier litter and improved flock hygiene. In contrast, manual drinkers often lead to overfilling and accidental spills, increasing moisture levels that promote bacterial growth and elevate maintenance costs.

Automated Water Metering

Automated water metering in poultry farming enhances precision in water supply management, reducing waste and ensuring consistent hydration critical for optimal poultry health and growth. Compared to manual drinkers, automatic systems provide real-time data on water consumption, enabling timely adjustments and improved resource efficiency.

IoT-Enabled Waterers

IoT-enabled waterers in poultry farming offer precise monitoring and automated regulation of water supply, reducing waste and ensuring consistent hydration levels critical for bird health and growth. Compared to manual drinkers, these smart systems integrate sensor data and remote control capabilities, optimizing water usage efficiency and minimizing labor costs.

Manual vs Automatic drinkers for water supply Infographic

agridif.com

agridif.com