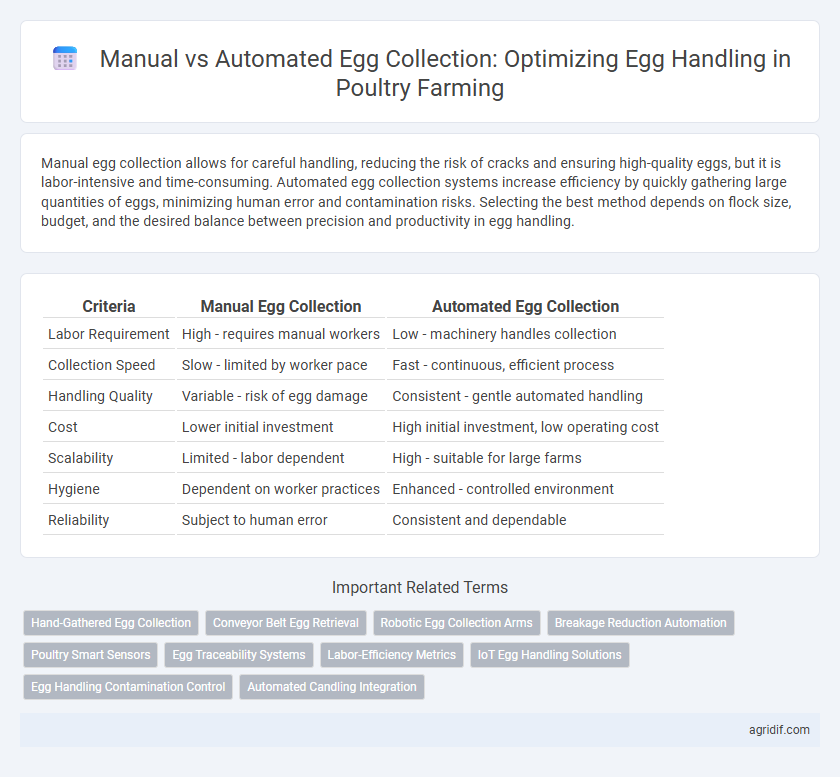

Manual egg collection allows for careful handling, reducing the risk of cracks and ensuring high-quality eggs, but it is labor-intensive and time-consuming. Automated egg collection systems increase efficiency by quickly gathering large quantities of eggs, minimizing human error and contamination risks. Selecting the best method depends on flock size, budget, and the desired balance between precision and productivity in egg handling.

Table of Comparison

| Criteria | Manual Egg Collection | Automated Egg Collection |

|---|---|---|

| Labor Requirement | High - requires manual workers | Low - machinery handles collection |

| Collection Speed | Slow - limited by worker pace | Fast - continuous, efficient process |

| Handling Quality | Variable - risk of egg damage | Consistent - gentle automated handling |

| Cost | Lower initial investment | High initial investment, low operating cost |

| Scalability | Limited - labor dependent | High - suitable for large farms |

| Hygiene | Dependent on worker practices | Enhanced - controlled environment |

| Reliability | Subject to human error | Consistent and dependable |

Introduction to Egg Collection Methods in Poultry Farming

Manual egg collection in poultry farming involves workers physically gathering eggs from nesting boxes, which allows for careful inspection but is labor-intensive and time-consuming. Automated egg collection systems use conveyor belts and sensors to efficiently transport eggs from nests to processing areas, reducing handling damage and labor costs. Choosing between manual and automated methods depends on farm scale, labor availability, and investment capacity to optimize egg quality and operational efficiency.

Overview of Manual Egg Collection

Manual egg collection involves workers gathering eggs by hand directly from nesting boxes or floors, ensuring careful handling to minimize breakage and contamination. This method allows for immediate inspection of eggs for quality and cleanliness, which is critical in small-scale or free-range poultry operations. Despite being labor-intensive and time-consuming, manual collection provides flexibility in managing eggs with various sizes and conditions.

Overview of Automated Egg Collection Systems

Automated egg collection systems utilize conveyor belts and sensors to transport eggs directly from the nesting area to processing stations, reducing manual labor and minimizing egg breakage. These systems enhance efficiency by maintaining consistent collection intervals and improving hygiene through enclosed transport mechanisms. Integration of automated egg collection with sorting and grading equipment streamlines the entire egg handling process, leading to better productivity and higher-quality output in poultry farming operations.

Labor Requirements: Manual vs Automated Egg Handling

Manual egg collection in poultry farming demands significant labor input, often requiring workers to collect eggs multiple times a day, which increases operational costs and labor fatigue. Automated egg collection systems drastically reduce labor requirements by using conveyor belts and robotic arms to transport eggs directly from nests to packing stations, enhancing efficiency and consistency. This automation not only minimizes human error but also allows poultry farms to allocate labor resources to other critical tasks, improving overall productivity.

Efficiency and Productivity Comparison

Manual egg collection in poultry farming often results in lower efficiency due to increased labor time and higher risks of egg damage during handling. Automated egg collection systems enhance productivity by reducing human error, ensuring consistent egg quality, and enabling faster processing rates. Integration of automated conveyors and sensors streamlines the workflow, significantly boosting overall farm output and operational efficiency.

Egg Quality and Breakage Rates

Manual egg collection in poultry farming often results in higher egg breakage rates due to inconsistent handling and delayed collection times, which can compromise egg quality with increased contamination risks. Automated egg collection systems enhance egg quality by ensuring timely and gentle handling, drastically reducing breakage through standardized processes. These systems also improve overall farm efficiency and maintain shell integrity, promoting better shelf life and consumer satisfaction.

Initial Investment and Operational Costs

Manual egg collection requires lower initial investment, primarily involving labor costs and simple equipment, but incurs higher ongoing operational expenses due to continuous labor payments and increased risk of egg damage. Automated egg collection systems demand a substantial upfront investment in conveyor belts, sensors, and storage units, yet significantly reduce long-term operational costs by minimizing labor requirements and improving egg handling efficiency. Farms seeking scalability and cost-efficiency often prefer automated systems despite the higher initial capital outlay.

Biosecurity and Hygiene Considerations

Manual egg collection in poultry farming increases the risk of contamination due to frequent human contact, potentially introducing pathogens and compromising biosecurity. Automated egg collection systems reduce handling time and human intervention, minimizing the spread of bacteria such as Salmonella and improving overall hygiene standards. Enhanced cleanliness protocols integrated with automated systems ensure consistent biosecurity compliance and lower cross-contamination risks in egg handling processes.

Scalability for Small and Large-Scale Farms

Manual egg collection suits small-scale poultry farms due to low initial investment and direct control over egg handling, but limits scalability as labor demands increase with flock size. Automated egg collection systems enhance scalability for large-scale farms by increasing efficiency, reducing labor costs, and minimizing egg damage through mechanized conveyors and sensors. Integration of automated systems supports consistent egg quality and faster processing, essential for meeting high-volume production targets.

Future Trends in Egg Collection Technology

Automated egg collection systems are increasingly integrated with IoT sensors and AI-driven monitoring to enhance efficiency and reduce labor costs in poultry farming. Future trends emphasize real-time data analytics for egg quality assessment and predictive maintenance of conveyor belts to minimize downtime. Manual egg collection is gradually being supplemented or replaced by technologies designed to improve hygiene and traceability throughout the egg handling process.

Related Important Terms

Hand-Gathered Egg Collection

Hand-gathered egg collection in poultry farming allows for careful inspection of each egg, reducing the risk of damage and contamination while enabling immediate removal of defective or dirty eggs. This manual approach supports small-scale operations by minimizing initial investment costs and offering greater control over egg quality management compared to automated systems.

Conveyor Belt Egg Retrieval

Manual egg collection in poultry farming involves workers gathering eggs by hand, which can lead to higher labor costs and increased risk of egg breakage. Automated egg collection systems using conveyor belt egg retrieval improve efficiency, reduce damage, and streamline handling by transporting eggs directly from nests to packing stations.

Robotic Egg Collection Arms

Robotic egg collection arms significantly enhance efficiency and reduce labor costs in poultry farming by automating the egg handling process, minimizing egg breakage through precise, gentle movements. These advanced systems integrate with conveyor belts and smart sensors to ensure timely collection and maintain optimal egg quality compared to manual methods.

Breakage Reduction Automation

Automated egg collection systems significantly reduce breakage by using gentle conveyor belts and cushioned handling processes, minimizing human contact and mechanical impact. Manual egg collection often leads to higher breakage rates due to inconsistent handling and increased risk of drops during transport.

Poultry Smart Sensors

Poultry smart sensors integrated into automated egg collection systems enhance egg handling by providing real-time monitoring of egg quality, temperature, and humidity, significantly reducing manual labor and minimizing egg breakage. These sensors enable precise tracking and data analytics, optimizing flock management efficiency compared to traditional manual egg collection methods.

Egg Traceability Systems

Manual egg collection often limits the integration of advanced egg traceability systems due to human error and slower data recording processes, impacting the accuracy of tracking provenance and quality control. Automated egg collection enhances traceability by utilizing barcode scanning or RFID technology, enabling real-time monitoring and precise data capture throughout the supply chain.

Labor-Efficiency Metrics

Manual egg collection requires significant labor hours per thousand eggs, often ranging from 15 to 30 minutes, which increases operational costs and limits scalability in large poultry farms. Automated egg collection systems reduce labor time by up to 80%, improve handling speed with conveyor belts and sensor technology, and enhance overall labor efficiency by allowing farm workers to focus on monitoring and maintenance rather than manual collection.

IoT Egg Handling Solutions

Manual egg collection in poultry farming is labor-intensive, prone to human error, and can lead to egg damage, while automated egg collection systems integrated with IoT egg handling solutions ensure real-time monitoring, optimize collection efficiency, and reduce breakage rates. IoT-enabled sensors and data analytics enhance egg quality tracking, improve inventory management, and facilitate predictive maintenance of automated equipment for sustainable farm operations.

Egg Handling Contamination Control

Manual egg collection increases the risk of contamination due to frequent human contact and inconsistent handling practices, potentially introducing bacteria like Salmonella. Automated egg collection systems minimize contamination by reducing direct contact and incorporating controlled environments with cleaning protocols, enhancing overall egg hygiene and safety.

Automated Candling Integration

Automated egg collection systems integrated with candling technology enhance egg handling efficiency by detecting internal defects and improving sorting accuracy, reducing labor costs and minimizing egg breakage. This seamless integration accelerates processing speed and ensures higher product quality compared to manual egg collection methods.

Manual egg collection vs Automated egg collection for egg handling Infographic

agridif.com

agridif.com