Manual egg collection in poultry farming allows for careful handling and inspection of eggs, reducing damage and ensuring quality control. Automated egg collection systems increase efficiency and reduce labor costs by using conveyor belts and sensors to gather eggs quickly and hygienically. Choosing between manual and automated methods depends on farm size, budget, and desired productivity levels.

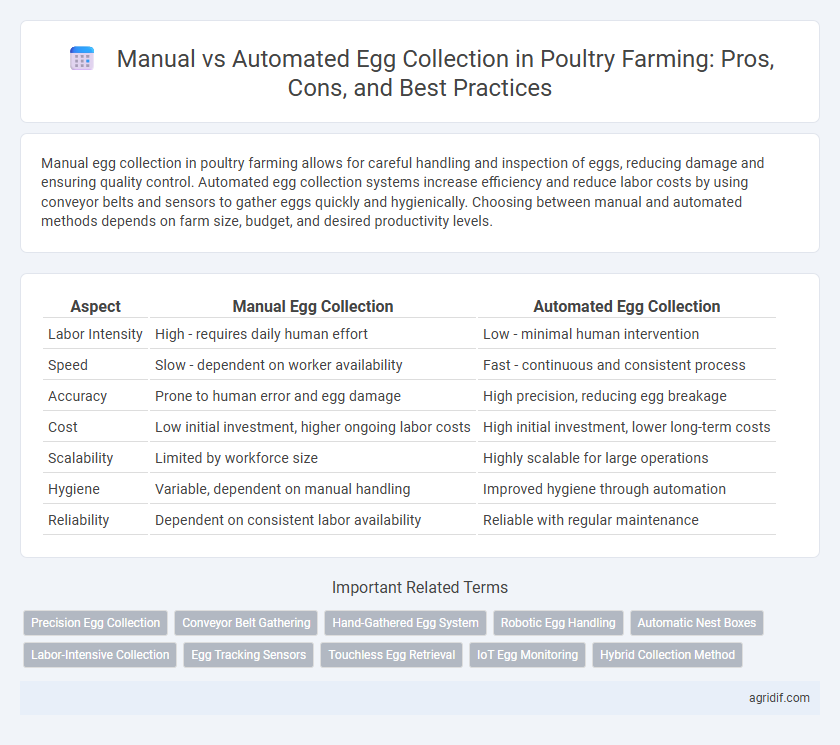

Table of Comparison

| Aspect | Manual Egg Collection | Automated Egg Collection |

|---|---|---|

| Labor Intensity | High - requires daily human effort | Low - minimal human intervention |

| Speed | Slow - dependent on worker availability | Fast - continuous and consistent process |

| Accuracy | Prone to human error and egg damage | High precision, reducing egg breakage |

| Cost | Low initial investment, higher ongoing labor costs | High initial investment, lower long-term costs |

| Scalability | Limited by workforce size | Highly scalable for large operations |

| Hygiene | Variable, dependent on manual handling | Improved hygiene through automation |

| Reliability | Dependent on consistent labor availability | Reliable with regular maintenance |

Introduction to Egg Collection Methods

Egg collection methods in poultry farming significantly impact efficiency and labor costs. Manual collection involves workers gathering eggs by hand, offering flexibility but increasing labor intensity and risk of egg damage. Automated systems utilize conveyor belts and sensors to reduce handling time, improve egg quality, and enhance biosecurity by minimizing human contact.

Overview of Manual Egg Collection

Manual egg collection in poultry farming involves workers gathering eggs by hand from nests or cages, ensuring careful handling to minimize damage and contamination. This traditional method allows for immediate inspection of eggs for quality and cleanliness, though it is labor-intensive and time-consuming. Manual collection is often favored in small to medium-sized operations where automation costs are prohibitive or where close monitoring of individual birds is required.

Understanding Automated Egg Collection Systems

Automated egg collection systems utilize conveyor belts and sensors to efficiently transport eggs from the nesting area to a centralized collection point, reducing labor and minimizing egg damage. These systems enhance productivity by maintaining consistent egg quality and allowing real-time monitoring of egg count and nest conditions through integrated software. Implementing automated solutions in poultry farming improves operational efficiency and supports scalable egg production.

Efficiency Comparison: Manual vs Automated

Automated egg collection systems significantly enhance efficiency by reducing labor costs and minimizing egg damage, achieving collection rates up to 99% with consistent speed. Manual collection requires continuous human intervention, often leading to slower turnaround times and higher risk of contamination or breakage during handling. Implementing automated systems optimizes throughput in large-scale poultry operations, ensuring timely collection and improved egg quality control.

Labor Requirements and Workforce Impacts

Manual egg collection in poultry farming demands intensive labor, requiring workers to handle daily gathering and transportation, which increases workforce size and human error risk. Automated egg collection systems significantly reduce labor requirements by using conveyor belts and sensors, enabling fewer workers to manage larger operations efficiently. This shift minimizes physical strain on staff, lowers labor costs, and improves productivity while potentially displacing low-skilled jobs in the sector.

Egg Quality and Handling Differences

Manual egg collection allows for careful handling, reducing the risk of cracks and contamination, which helps maintain superior egg quality. Automated systems increase collection speed and efficiency but may cause minor surface damage due to mechanical handling, potentially affecting the shell's integrity. The choice between manual and automated collection impacts both egg quality and handling protocols, influencing overall farm productivity and product standards.

Cost Analysis: Initial Investment and Maintenance

Manual egg collection in poultry farming involves lower initial investment costs, primarily requiring basic equipment and labor, but incurs higher ongoing labor expenses and risks of inconsistent collection rates. Automated egg collection systems demand significant upfront capital for machinery, such as conveyor belts and sensors, yet reduce labor costs and improve efficiency through consistent egg handling and minimized breakage. Maintenance costs for automated systems include periodic mechanical repairs and software updates, which can be offset by increased productivity and reduced egg damage over time.

Biosecurity and Hygiene Considerations

Manual egg collection in poultry farming often increases the risk of contamination due to frequent human contact, which can introduce pathogens and compromise biosecurity. Automated egg collection systems minimize handling, enhancing hygiene by reducing cross-contamination and allowing for timely removal of eggs, thus preventing bacterial growth. Implementing automated systems improves consistent sanitation protocols and biosecurity measures critical for maintaining flock health and reducing disease transmission.

Scalability for Small and Large Poultry Farms

Manual egg collection suits small-scale poultry farms with limited flock sizes, offering low initial costs and direct oversight but reduced efficiency as flock size grows. Automated egg collection systems significantly enhance scalability for large poultry operations by increasing collection speed, reducing labor costs, and minimizing egg damage through consistent handling. Implementing automation supports high-volume production and improved biosecurity, making it essential for commercial-scale poultry farms aiming for operational efficiency.

Future Trends in Egg Collection Technology

Future trends in egg collection technology emphasize automated systems integrating robotics and AI to enhance efficiency and reduce labor costs in poultry farming. Advanced sensors and data analytics enable real-time monitoring of egg quality and hen health, optimizing production outcomes. Manual collection remains relevant in small-scale operations, but widespread adoption of automation driven by smart technology is set to revolutionize large-scale egg production.

Related Important Terms

Precision Egg Collection

Precision egg collection in poultry farming significantly improves with automated systems, which reduce the risk of egg damage and contamination by ensuring consistent handling and timely removal. Manual collection often leads to variability in timing and handling, increasing the chances of cracked eggs and lowering overall egg quality compared to automated solutions.

Conveyor Belt Gathering

Conveyor belt gathering in poultry farming automates egg collection, significantly reducing labor costs and minimizing egg breakage compared to manual collection methods. Automated systems enhance efficiency by continuously transporting eggs from nesting areas to packing stations, ensuring faster processing and improved hygiene control.

Hand-Gathered Egg System

Hand-gathered egg systems in poultry farming offer precise egg collection with minimal equipment costs, allowing farm workers to inspect eggs individually for quality and cleanliness. While manual collection can be labor-intensive and time-consuming, it reduces breakage rates and enables better immediate detection of defects compared to automated systems.

Robotic Egg Handling

Robotic egg handling systems enhance poultry farming efficiency by reducing labor costs and minimizing egg breakage through precise, automated collection processes. These advanced technologies integrate sensors and AI-driven mechanisms to optimize egg sorting, cleaning, and packaging, ensuring consistent quality and increased productivity compared to manual methods.

Automatic Nest Boxes

Automatic nest boxes in poultry farming enhance egg collection efficiency by reducing labor costs and minimizing egg damage through gentle handling and real-time monitoring. These systems integrate sensors and conveyors to ensure consistent egg quality and improve overall farm productivity.

Labor-Intensive Collection

Manual egg collection in poultry farming is highly labor-intensive, requiring workers to frequently enter hen houses to gather eggs, which increases labor costs and risk of egg damage. Automated egg collection systems significantly reduce manual labor by using conveyor belts and sensors, improving efficiency and minimizing breakage while allowing more consistent monitoring of egg production.

Egg Tracking Sensors

Egg tracking sensors in automated poultry farming systems enhance accuracy in monitoring egg production and quality, reducing human error and labor costs compared to manual collection methods. These sensors enable real-time data collection and integration with farm management software, improving inventory control and traceability throughout the supply chain.

Touchless Egg Retrieval

Touchless egg retrieval systems in automated poultry farming significantly reduce contamination risk by minimizing human handling, enhancing egg cleanliness and biosecurity. Manual egg collection, while cost-effective initially, increases labor demands and potential egg damage, making automated, touchless solutions more efficient for large-scale operations.

IoT Egg Monitoring

IoT egg monitoring systems in poultry farming enable automated egg collection by using sensors to track egg status, temperature, and humidity in real-time, significantly improving efficiency compared to manual methods. Automated systems reduce labor costs, minimize egg damage, and provide data analytics that optimize flock management and egg production quality.

Hybrid Collection Method

The hybrid collection method in poultry farming combines manual and automated egg collection systems to optimize efficiency and reduce breakage rates, ensuring higher throughput and better egg quality. This approach leverages automation for routine collection while utilizing manual inspection to maintain quality control and address irregularities promptly.

Manual vs Automated for egg collection Infographic

agridif.com

agridif.com