On-floor brooding offers chicks more space to move freely, promoting natural behavior and reducing stress, while battery brooding involves confined cages that may restrict movement but allow for easier management and higher stocking densities. On-floor systems require careful temperature and hygiene control to prevent disease, whereas battery cages facilitate waste removal and monitoring but can increase the risk of injury due to crowding. Choosing between on-floor and battery brooding depends on balancing animal welfare concerns with production efficiency in poultry farming.

Table of Comparison

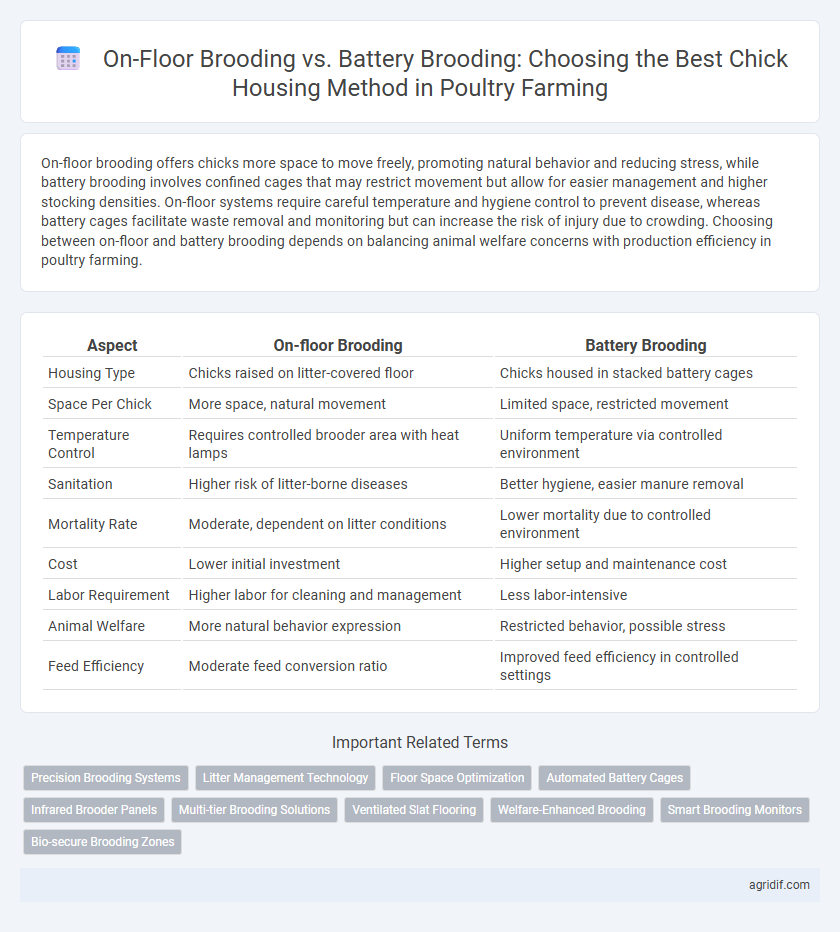

| Aspect | On-floor Brooding | Battery Brooding |

|---|---|---|

| Housing Type | Chicks raised on litter-covered floor | Chicks housed in stacked battery cages |

| Space Per Chick | More space, natural movement | Limited space, restricted movement |

| Temperature Control | Requires controlled brooder area with heat lamps | Uniform temperature via controlled environment |

| Sanitation | Higher risk of litter-borne diseases | Better hygiene, easier manure removal |

| Mortality Rate | Moderate, dependent on litter conditions | Lower mortality due to controlled environment |

| Cost | Lower initial investment | Higher setup and maintenance cost |

| Labor Requirement | Higher labor for cleaning and management | Less labor-intensive |

| Animal Welfare | More natural behavior expression | Restricted behavior, possible stress |

| Feed Efficiency | Moderate feed conversion ratio | Improved feed efficiency in controlled settings |

Introduction to Chick Brooding Systems

On-floor brooding and battery brooding represent two primary chick housing systems utilized in poultry farming to optimize early chick development and survival rates. On-floor brooding allows chicks to move freely on littered flooring, promoting natural behavior and better thermoregulation, while battery brooding confines chicks in stacked cages, enhancing space efficiency and ease of management. Choosing the appropriate brooding method significantly impacts chick growth performance, welfare standards, and operational costs within commercial poultry production.

Overview of On-floor Brooding

On-floor brooding in poultry farming involves raising chicks directly on the poultry house floor covered with litter material, providing a natural and spacious environment that supports movement and social behavior. This method promotes better air circulation and reduces stress, helping maintain uniform growth and health among chicks. Compared to battery brooding, on-floor brooding minimizes initial setup costs and allows easier management of temperature and humidity levels within the brooding area.

Overview of Battery Brooding

Battery brooding in poultry farming involves housing chicks in multi-tiered battery cages, offering controlled temperature, ventilation, and easy waste management. This method enhances space efficiency, reduces labor costs, and minimizes disease spread by separating individual birds. Battery brooding supports optimized growth rates and uniform chick development through automated environmental controls.

Key Differences between On-floor and Battery Brooding

On-floor brooding involves raising chicks directly on a litter-covered floor, promoting natural movement and social interaction, while battery brooding confines chicks in stacked cages designed for space efficiency and ease of management. On-floor brooding supports better air circulation and reduces ammonia buildup, enhancing bird health, whereas battery brooding enables easier monitoring and sanitation but may restrict chick behavior. Key differences include space allocation, ventilation quality, chick welfare, disease control, and labor intensity, making on-floor brooding more welfare-oriented and battery brooding more suitable for high-density production systems.

Advantages of On-floor Brooding

On-floor brooding in poultry farming provides better natural movement and space for chicks, promoting healthier growth and reducing stress compared to battery brooding. The method enhances ventilation and temperature control, contributing to improved chick comfort and reduced disease risk. Farmers benefit from easier management and cost-effectiveness due to lower infrastructure requirements and flexible space utilization.

Advantages of Battery Brooding

Battery brooding offers precise temperature control for each chick compartment, promoting uniform growth and reducing mortality rates. This method enhances biosecurity by minimizing cross-contamination through individual housing units, leading to better health management. Efficient space utilization in battery systems allows higher stocking densities without compromising chick comfort or welfare.

Challenges and Limitations of On-floor Brooding

On-floor brooding presents challenges such as uneven heat distribution, higher risk of disease transmission due to litter contact, and increased labor for managing bedding and waste. Poor temperature control can lead to stressed chicks and impaired growth, while ammonia buildup from manure negatively affects respiratory health. These limitations often result in increased mortality rates and reduced overall flock performance compared to battery brooding systems.

Challenges and Limitations of Battery Brooding

Battery brooding in poultry farming faces significant challenges such as limited space per chick, which restricts natural movement and contributes to higher stress levels and increased susceptibility to diseases. The rigid infrastructure of battery cages limits proper ventilation and temperature control, resulting in uneven brooding conditions that can affect chick growth and mortality rates. Additionally, battery brooding systems often struggle with waste management, leading to hygiene issues that further compromise the health and welfare of the chicks.

Economic Considerations for Brooding Systems

On-floor brooding requires lower initial capital investment compared to battery brooding, making it accessible for small-scale poultry farmers. Battery brooding offers higher space efficiency and reduces labor costs through automated systems, leading to better long-term economic returns. Feed conversion ratios and mortality rates are critical economic factors influenced by brooding methods, impacting overall profitability in poultry farming.

Choosing the Right Brooding System for Your Poultry Farm

On-floor brooding offers better natural movement and comfort for chicks, promoting healthier growth through ample space and reduced stress. Battery brooding provides controlled environmental conditions, optimizing temperature and hygiene but may limit chick mobility and natural behaviors. Selecting the right brooding system depends on farm size, management capacity, and priorities for chick welfare versus production efficiency.

Related Important Terms

Precision Brooding Systems

Precision brooding systems enhance on-floor brooding by maintaining stable temperature, humidity, and ventilation to optimize chick comfort and growth, whereas battery brooding relies on enclosed cages that limit movement and natural behaviors. Advanced precision brooding facilitates uniform chick development, reduces mortality rates, and improves feed efficiency compared to traditional battery brooding setups.

Litter Management Technology

On-floor brooding utilizes deep litter bedding that requires advanced litter management technology to maintain optimal moisture levels and reduce ammonia, enhancing chick health and growth conditions. Battery brooding systems rely on wire mesh flooring which minimizes direct contact with litter, thereby reducing pathogen buildup but necessitating precise waste disposal methods to prevent environmental contamination.

Floor Space Optimization

On-floor brooding maximizes floor space utilization by allowing chicks to move freely, promoting natural behaviors and efficient heat distribution, whereas battery brooding confines chicks in stacked cages, reducing overall usable floor area but facilitating intensive management. Optimizing floor space in poultry housing depends on balancing chick welfare with production goals, where on-floor brooding offers more flexible spatial arrangements and potential for higher stocking densities without compromising health.

Automated Battery Cages

Automated battery cages in poultry farming enhance on-floor brooding efficiency by providing uniform temperature control, reduced labor costs, and improved chick health through precise environmental management. These systems optimize space utilization and biosecurity while minimizing feed wastage and mortality rates compared to traditional on-floor brooding methods.

Infrared Brooder Panels

Infrared brooder panels in on-floor brooding provide targeted, consistent heat that mimics natural warmth, enhancing chick comfort and growth compared to the uniform but less flexible heating in battery brooding systems. These panels reduce energy consumption and improve air quality by minimizing airflow disruption, leading to healthier early development in chicks.

Multi-tier Brooding Solutions

Multi-tier brooding solutions in poultry farming optimize space utilization and improve temperature control compared to traditional on-floor brooding and battery brooding methods. These systems enhance chick comfort and uniform growth by maintaining consistent heat and ventilation across tiers, reducing mortality rates and boosting overall production efficiency.

Ventilated Slat Flooring

Ventilated slat flooring in on-floor brooding enhances air circulation and waste management, reducing ammonia levels and improving chick health compared to traditional battery brooding systems. This flooring type supports natural behaviors by providing a cleaner, drier environment, which leads to better growth rates and lower mortality in poultry housing.

Welfare-Enhanced Brooding

On-floor brooding enhances chick welfare by providing natural movement space and improved ventilation, reducing stress and promoting healthier growth compared to battery brooding systems that restrict mobility and often cause higher stress levels. Studies show that welfare-enhanced brooding methods, such as on-floor systems, result in better leg health, lower mortality rates, and increased overall well-being in poultry production.

Smart Brooding Monitors

Smart brooding monitors enhance on-floor brooding by providing precise temperature, humidity, and lighting control directly within the chick's environment, promoting healthier growth and reduced mortality rates. In battery brooding, these advanced sensors enable continuous real-time data collection, optimizing ventilation and feed delivery systems for improved efficiency and uniform chick development.

Bio-secure Brooding Zones

On-floor brooding creates expansive bio-secure brooding zones by minimizing structural complexity and facilitating thorough sanitation, significantly reducing pathogen accumulation compared to battery brooding systems. Battery brooding, with its confined cages, increases biosecurity risks due to limited airflow and higher potential for cross-contamination among chicks.

On-floor Brooding vs Battery Brooding for Chick Housing Infographic

agridif.com

agridif.com