Choosing between straight run and sexed chicks is essential for efficient poultry farming, as straight run chicks consist of mixed sexes sold without sorting, making them cost-effective but less predictable in flock composition. Sexed chicks are carefully separated by gender, allowing farmers to select females for egg production or males for meat, optimizing resource allocation and management. Understanding these differences helps poultry farmers tailor their needs for pet care, egg laying, or meat production.

Table of Comparison

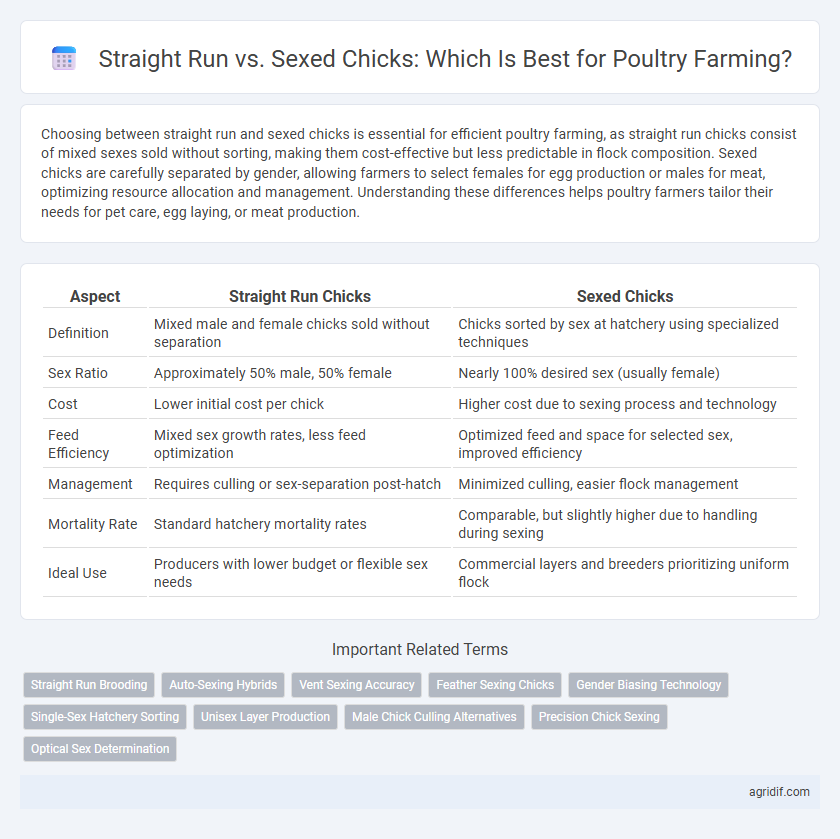

| Aspect | Straight Run Chicks | Sexed Chicks |

|---|---|---|

| Definition | Mixed male and female chicks sold without separation | Chicks sorted by sex at hatchery using specialized techniques |

| Sex Ratio | Approximately 50% male, 50% female | Nearly 100% desired sex (usually female) |

| Cost | Lower initial cost per chick | Higher cost due to sexing process and technology |

| Feed Efficiency | Mixed sex growth rates, less feed optimization | Optimized feed and space for selected sex, improved efficiency |

| Management | Requires culling or sex-separation post-hatch | Minimized culling, easier flock management |

| Mortality Rate | Standard hatchery mortality rates | Comparable, but slightly higher due to handling during sexing |

| Ideal Use | Producers with lower budget or flexible sex needs | Commercial layers and breeders prioritizing uniform flock |

Understanding Straight Run and Sexed Chicks

Straight run chicks consist of an unsexed mix of males and females, commonly selected for general poultry farming due to their lower cost and natural distribution. Sexed chicks, identified through vent sexing or feather sexing, enable farmers to purchase predominantly female layers or male broilers, optimizing flock performance based on production goals. Understanding the economic trade-offs and management requirements between straight run and sexed chicks is critical for efficient poultry farm operations.

Key Differences Between Straight Run and Sexed Chicks

Straight run chicks consist of mixed genders sold without sorting, resulting in a natural 50:50 male-to-female ratio, ideal for farmers raising both meat and egg-producing birds. Sexed chicks are separated by gender using genetic or feather sexing techniques, offering higher upfront costs but enabling optimized flock management with females for egg production or males for meat yield. Selecting between straight run and sexed chicks impacts growth rates, feed conversion, and overall farm profitability based on production goals and resource allocation.

Pros and Cons of Straight Run Chicks

Straight run chicks, which consist of mixed-sex populations, offer cost savings since they are less expensive than sexed chicks but require more space and resources due to the presence of unwanted males. They enable natural selection and often exhibit robust health, but managing mixed sexes can lead to challenges in flock uniformity and productivity, especially in layers where males are non-productive. Farmers must balance lower initial investment against potential inefficiencies in feed usage and housing, considering their specific production goals and capacity.

Benefits of Choosing Sexed Chicks

Sexed chicks provide the advantage of precise gender identification at hatch, enabling poultry farmers to optimize flock composition for specific production goals such as egg or meat production. This targeted selection reduces feed costs and resource allocation by eliminating the rearing of unwanted genders, increasing overall operational efficiency. Choosing sexed chicks enhances productivity by aligning flock management with market demands and improving profitability in poultry farming operations.

Cost Comparison: Straight Run vs. Sexed Chicks

Straight run chicks typically cost less than sexed chicks due to the simpler hatching process and lack of sex identification technology. Sexed chicks, which are selectively sorted by gender, carry higher upfront costs that can be offset by improved flock management and reduced feed wastage. Choosing between straight run and sexed chicks depends on farm scale and labor resources, balancing initial expense against long-term operational efficiency.

Impact on Flock Management

Choosing straight run chicks affects flock management by introducing a mixed-gender population, which can complicate feeding, housing, and space requirements due to varying growth rates and behavior between males and females. Sexed chicks offer more precise control over flock composition, allowing farmers to optimize resources, focus on specific production goals such as egg laying or meat yield, and reduce management challenges related to gender differences. This targeted selection improves overall efficiency, minimizes feed waste, and tailors flock care to the distinct needs of the chosen sex.

Suitability for Egg Production or Meat

Straight run chicks, which include both males and females, are often preferred for meat production due to balanced growth rates and lower costs, while sexed chicks, separated by gender at hatch, are more suitable for egg production since only females are raised for laying purposes. Sexed female chicks allow poultry farmers to optimize flock management and feed efficiency by targeting egg-laying birds, reducing wasted resources on males that do not contribute to egg output. Choosing between straight run and sexed chicks depends on the production goal: meat-focused operations benefit from straight runs, whereas egg producers gain efficiency and productivity from sexed female chicks.

Factors to Consider When Selecting Chicks

Selecting between straight run and sexed chicks depends largely on the intended flock purpose and budget constraints. Straight run chicks, being unsexed, offer a lower cost but require additional resources to manage the varying sex ratio, which can affect flock uniformity and productivity. In contrast, sexed chicks provide a higher initial investment with the advantage of predictable gender ratios, optimizing space allocation and feed efficiency for specialized poultry production.

Best Practices for Chick Purchasing

Selecting straight run chicks involves purchasing mixed-gender flocks, which can be cost-effective but requires managing a variable ratio of males to females, ideal for growers prioritizing quantity over gender specificity. Sexed chicks offer precision by ensuring predominantly female birds, reducing feed and space costs associated with non-laying males, making them suitable for targeted egg production operations. Best practices for chick purchasing include verifying breeder reputation, understanding the farm's production goals, and assessing chick health certifications to optimize flock performance and sustainability.

Making the Right Choice for Your Poultry Farm

Choosing between straight run and sexed chicks hinges on your farm's production goals and cost considerations. Straight run chicks offer a lower upfront cost but result in an unpredictable male-to-female ratio, potentially requiring culling or separate management of roosters. Sexed chicks provide a nearly 99% accurate female selection, enhancing feed efficiency and space utilization by focusing on egg-laying hens or meat production, making them ideal for precise flock planning.

Related Important Terms

Straight Run Brooding

Straight run brooding involves raising mixed-sex chicks without early sex separation, allowing for natural growth patterns and simpler management during initial stages. This method reduces upfront costs compared to sexed chicks but requires later sorting to separate males and females for specific production goals.

Auto-Sexing Hybrids

Auto-sexing hybrids in poultry farming allow for immediate visual differentiation between male and female chicks based on plumage color, enhancing efficiency in chick selection compared to traditional straight run or sexed chicks. These breeds reduce labor costs and errors associated with manual sexing, improving overall flock management and productivity.

Vent Sexing Accuracy

Vent sexing accuracy in poultry farming significantly influences the choice between straight run and sexed chicks; sexed chicks typically offer 95-98% accuracy, ensuring precise female or male selection, while straight run chicks have a 50% chance of being either sex. This difference impacts farm efficiency and resource allocation, as growers relying on vent sexing can optimize space and feed by exclusively raising the desired sex.

Feather Sexing Chicks

Feather sexing chicks allows poultry farmers to efficiently distinguish between male and female chicks shortly after hatching, enabling precise selection for desired flock composition. This method reduces costs and increases productivity compared to straight run chicks by minimizing the rearing of unwanted sexes.

Gender Biasing Technology

Gender biasing technology in poultry farming enhances chick selection by accurately identifying sex at an early stage, influencing the choice between straight run and sexed chicks. Using sexed chicks reduces costs and resource waste by ensuring only desired genders are raised, while straight run chicks offer a mixed-gender batch with flexible applications.

Single-Sex Hatchery Sorting

Single-sex hatchery sorting involves separating chicks by sex at an early stage, allowing poultry farmers to optimize flock composition with sex-specific management strategies. This method reduces feed costs and improves overall productivity compared to straight run chicks, where males and females are not separated, leading to potential inefficiencies in raising unwanted sex groups.

Unisex Layer Production

Sexed chicks in unisex layer production offer higher accuracy in gender identification, ensuring a predominantly female flock ideal for egg production, while straight run chicks present a cost-effective option but result in mixed genders requiring culling of males. Utilizing sexed chicks maximizes resource efficiency and productivity by reducing feed consumption and space allocated to non-laying males.

Male Chick Culling Alternatives

Straight run chicks, which include both males and females, often lead to male chick culling as males are less valuable for egg production, prompting the exploration of sexed chicks that enable farmers to select only females at hatch and significantly reduce the need for culling. Innovative male chick culling alternatives include in-ovo sexing technology and repurposing male chicks for meat production or animal feed, enhancing ethical practices and economic efficiency in poultry farming.

Precision Chick Sexing

Precision chick sexing technology enhances accuracy in identifying sex-specific traits, enabling poultry farmers to select sexed chicks for targeted flock composition, reducing feed waste and optimizing growth rates. Straight run chicks, comprising a mixed-sex group, offer cost advantages but increase uncertainty in gender distribution, potentially impacting production efficiency.

Optical Sex Determination

Optical sex determination in poultry farming enables the identification of female and male chicks at hatch, crucial for optimizing flock composition and reducing resource waste. Sexed chicks, sorted with high accuracy by this method, improve efficiency in layer production compared to straight run chicks, which include an unsexed mix of males and females.

Straight Run vs Sexed Chicks for Chick Selection Infographic

agridif.com

agridif.com