Telematics systems provide real-time data transmission and remote monitoring for precision agriculture machinery, enabling proactive maintenance and improved operational efficiency. Standalone systems, while effective for localized data collection, lack the connectivity and integration capabilities of telematics, limiting their ability to support comprehensive fleet management. Choosing telematics over standalone systems enhances decision-making by delivering continuous insights into equipment performance and location.

Table of Comparison

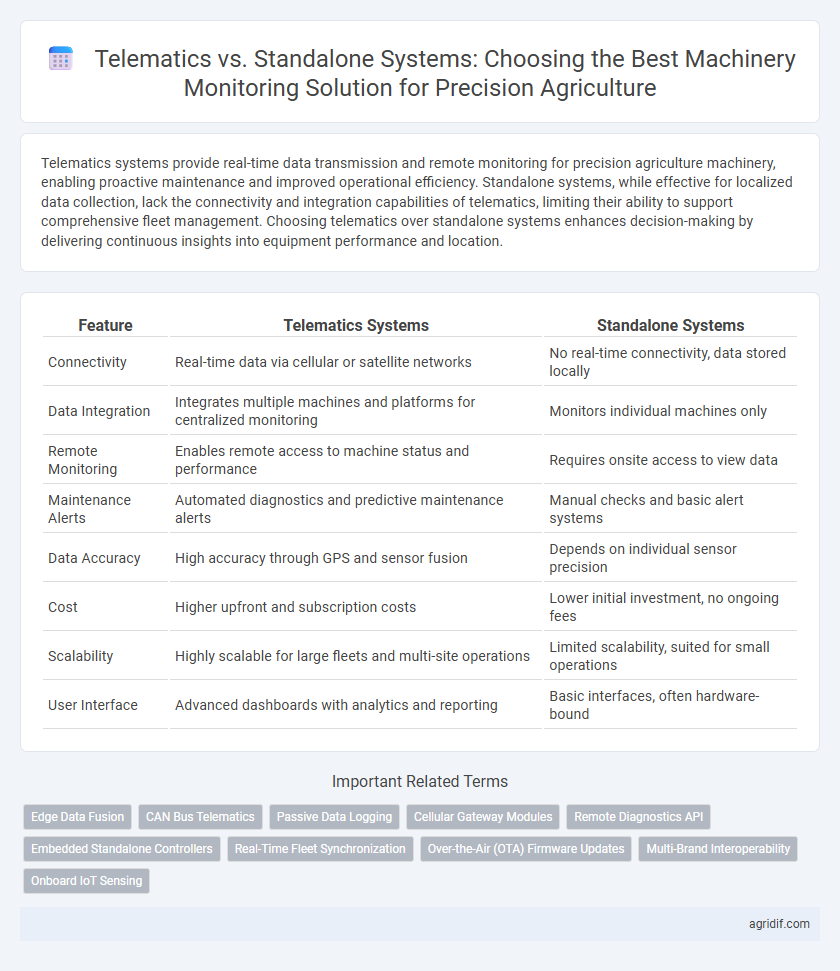

| Feature | Telematics Systems | Standalone Systems |

|---|---|---|

| Connectivity | Real-time data via cellular or satellite networks | No real-time connectivity, data stored locally |

| Data Integration | Integrates multiple machines and platforms for centralized monitoring | Monitors individual machines only |

| Remote Monitoring | Enables remote access to machine status and performance | Requires onsite access to view data |

| Maintenance Alerts | Automated diagnostics and predictive maintenance alerts | Manual checks and basic alert systems |

| Data Accuracy | High accuracy through GPS and sensor fusion | Depends on individual sensor precision |

| Cost | Higher upfront and subscription costs | Lower initial investment, no ongoing fees |

| Scalability | Highly scalable for large fleets and multi-site operations | Limited scalability, suited for small operations |

| User Interface | Advanced dashboards with analytics and reporting | Basic interfaces, often hardware-bound |

Overview of Machinery Monitoring in Precision Agriculture

Machinery monitoring in precision agriculture utilizes telematics and standalone systems to optimize equipment performance and reduce downtime. Telematics systems offer real-time data transmission, enabling remote diagnostics, GPS tracking, and automated maintenance scheduling. Standalone systems provide localized data collection and analysis but lack the connectivity benefits, making telematics more effective for integrated farm management.

Defining Telematics Systems in Agriculture

Telematics systems in agriculture integrate GPS technology, sensors, and wireless communication to provide real-time machinery monitoring and data analytics, enabling precise decision-making and operational efficiency. Unlike standalone systems, telematics offer remote access to machine diagnostics, fuel consumption, and location tracking through cloud-based platforms, facilitating proactive maintenance and resource optimization. This connectivity enhances productivity by allowing farmers to manage equipment fleets dynamically and reduce downtime across expansive agricultural operations.

Understanding Standalone Monitoring Solutions

Standalone monitoring solutions in precision agriculture provide real-time data collection directly from machinery without relying on external communication networks. These systems integrate sensors and onboard processors to track equipment performance, fuel consumption, and operational hours independently. Understanding standalone solutions is critical for farms with limited connectivity, offering reliable insights that enhance maintenance scheduling and operational efficiency.

Key Differences Between Telematics and Standalone Systems

Telematics systems enable real-time, remote monitoring of agricultural machinery by integrating GPS, sensors, and wireless communication, whereas standalone systems operate independently without live data exchange. Telematics offers comprehensive fleet management, predictive maintenance, and data analytics, contrasting with the limited, localized monitoring functionality of standalone units. The seamless connectivity of telematics enhances operational efficiency and decision-making, while standalone systems primarily focus on basic machine diagnostics and status reporting.

Data Collection and Integration Capabilities

Telematics systems in precision agriculture offer real-time data collection and seamless integration with farm management software, enhancing machinery monitoring by providing comprehensive insights into operational efficiency and maintenance needs. Standalone systems collect localized machine performance data but often lack interoperability with broader digital platforms, limiting the ability to analyze data across multiple machines and operations. Advanced telematics optimize decision-making through centralized data aggregation, supporting predictive maintenance and improving overall farm productivity.

Real-Time Monitoring and Remote Accessibility

Telematics systems provide real-time monitoring and remote accessibility by integrating GPS, sensors, and wireless communication to deliver instant data on machinery performance and location. Standalone systems offer limited real-time insights and typically require on-site data retrieval or manual updates, restricting immediate decision-making. The advanced connectivity of telematics enhances precision agriculture by enabling proactive maintenance and efficient resource management.

Cost Analysis: Telematics vs Standalone Systems

Telematics systems for machinery monitoring often entail higher upfront costs due to integrated hardware and software solutions but provide comprehensive data analytics and real-time remote monitoring that can lead to long-term operational savings. Standalone systems typically have lower initial investment since they focus on basic monitoring functions without connectivity features, yet may incur increased labor and maintenance expenses due to limited automation. Evaluating total cost of ownership involves balancing initial expenditure against potential efficiency gains, data accessibility, and reduction in downtime enabled by telematics in precision agriculture machinery management.

Scalability and Future-Readiness in Machinery Monitoring

Telematics systems in precision agriculture offer superior scalability due to their cloud-based architecture, enabling seamless integration of new machinery and data sources without significant infrastructure changes. Standalone monitoring systems often face limitations in future-readiness because they require physical upgrades or replacements to incorporate advanced features or expand functionality. Investment in telematics ensures long-term adaptability and supports the increasing complexity of connected machinery ecosystems.

Compatibility with Existing Farm Equipment

Telematics systems offer superior compatibility with a wide range of existing farm equipment by integrating real-time data through standardized communication protocols, enabling seamless monitoring and control. Standalone systems often require specific hardware or software configurations, limiting their interoperability and necessitating costly upgrades or replacements. Choosing telematics ensures enhanced scalability and reduced downtime by leveraging the existing machinery infrastructure.

Deciding the Best System for Your Precision Agriculture Needs

Telematics systems in precision agriculture provide real-time data integration and remote monitoring of machinery, enabling enhanced operational efficiency and predictive maintenance. Standalone systems offer targeted functionality with potentially lower upfront costs but lack seamless connectivity and comprehensive data analytics. Choosing between telematics and standalone systems depends on farm size, budget, integration needs, and the desired level of data-driven decision-making for optimizing crop yields and resource management.

Related Important Terms

Edge Data Fusion

Edge data fusion enhances telematics systems by integrating real-time sensor data from multiple machinery components, enabling precise monitoring and predictive maintenance in precision agriculture. Standalone systems lack the comprehensive data aggregation capabilities of telematics, limiting their effectiveness in optimizing equipment performance and farm productivity.

CAN Bus Telematics

CAN Bus telematics systems provide real-time, integrated machinery monitoring by leveraging the Controller Area Network protocol for seamless data communication across vehicle components, enhancing predictive maintenance and operational efficiency. Standalone systems lack this network integration, often resulting in isolated data points that limit comprehensive diagnostics and timely decision-making in precision agriculture machinery management.

Passive Data Logging

Telematics systems provide real-time remote monitoring and predictive maintenance for agricultural machinery by transmitting passive data directly to cloud platforms, enhancing operational efficiency and reducing downtime. Standalone systems rely solely on onboard passive data logging without connectivity, limiting data accessibility and delaying critical decision-making for precision agriculture applications.

Cellular Gateway Modules

Cellular Gateway Modules enable real-time data transmission in precision agriculture by integrating telematics systems with machinery, offering enhanced connectivity and remote monitoring compared to standalone systems. These modules support seamless communication between agricultural equipment and cloud platforms, improving operational efficiency and predictive maintenance through continuous data flow via cellular networks.

Remote Diagnostics API

Telematics systems integrate Remote Diagnostics APIs to provide real-time machinery monitoring, enabling instant identification of performance issues and predictive maintenance in precision agriculture. Standalone systems lack this connectivity, limiting data access and delaying response times, which reduces operational efficiency on the field.

Embedded Standalone Controllers

Embedded standalone controllers in machinery monitoring offer real-time data processing directly on the equipment, reducing latency and enhancing reliability compared to telematics systems that depend on external networks. These controllers enable precise control of agricultural machinery functions, improving operational efficiency and minimizing downtime in precision agriculture applications.

Real-Time Fleet Synchronization

Telematics systems enable real-time fleet synchronization by continuously transmitting machinery data such as location, operational status, and performance metrics to a centralized platform, enhancing coordinated decision-making and efficiency on the field. Standalone systems lack this instant data integration, resulting in delayed communication and less effective fleet management for precision agriculture operations.

Over-the-Air (OTA) Firmware Updates

Over-the-Air (OTA) firmware updates in telematics systems enable real-time, remote software enhancements, ensuring precision agriculture machinery operates with the latest features and security patches without manual intervention. Standalone systems lack this capability, often requiring on-site updates that increase downtime and limit efficient machinery performance monitoring.

Multi-Brand Interoperability

Telematics systems enable seamless multi-brand interoperability by integrating data from diverse machinery brands into a unified platform, enhancing real-time monitoring and operational efficiency. Standalone systems often restrict compatibility to a single brand, limiting data consolidation and comprehensive fleet management in precision agriculture.

Onboard IoT Sensing

Onboard IoT sensing in precision agriculture enhances telematics by providing real-time data integration from machinery sensors, enabling comprehensive monitoring of equipment performance and operational efficiency. Standalone systems lack this connectivity, limiting data accuracy and responsiveness crucial for optimizing field operations and predictive maintenance.

Telematics vs Standalone Systems for machinery monitoring Infographic

agridif.com

agridif.com