Automatic Section Control (ASC) in precision agriculture enhances sprayer efficiency by precisely managing spray sections to eliminate overlap, reducing chemical waste and environmental impact. Unlike manual section control, which relies on operator skill and can result in inconsistent coverage and over-application, ASC uses GPS technology and sensors to automatically deactivate sprayer sections when coverage areas overlap. This technological advancement ensures uniform application, lowers input costs, and improves crop health by preventing excessive herbicide or pesticide distribution.

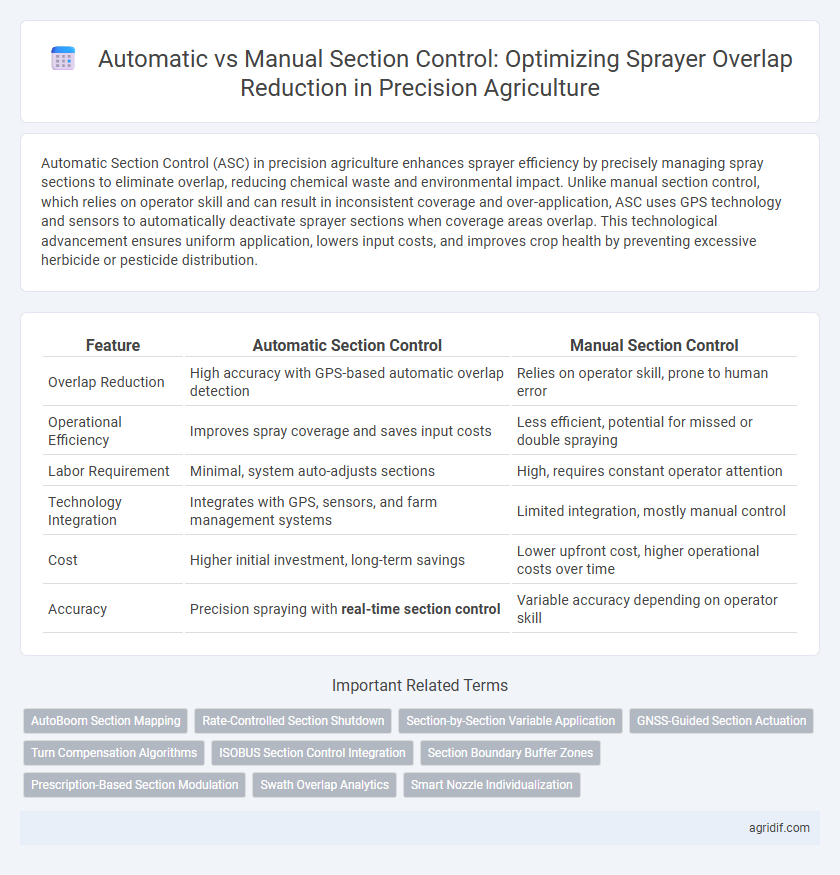

Table of Comparison

| Feature | Automatic Section Control | Manual Section Control |

|---|---|---|

| Overlap Reduction | High accuracy with GPS-based automatic overlap detection | Relies on operator skill, prone to human error |

| Operational Efficiency | Improves spray coverage and saves input costs | Less efficient, potential for missed or double spraying |

| Labor Requirement | Minimal, system auto-adjusts sections | High, requires constant operator attention |

| Technology Integration | Integrates with GPS, sensors, and farm management systems | Limited integration, mostly manual control |

| Cost | Higher initial investment, long-term savings | Lower upfront cost, higher operational costs over time |

| Accuracy | Precision spraying with real-time section control | Variable accuracy depending on operator skill |

Introduction to Section Control in Precision Agriculture

Automatic section control in precision agriculture uses GPS and sensor technology to precisely activate or deactivate sprayer sections, significantly reducing overlap and minimizing chemical waste. Manual section control relies on operator judgment, increasing the risk of overlapping sprays, which leads to inefficient input use and environmental concerns. Implementing automatic section control enhances application accuracy, lowers costs, and supports sustainable farming practices by optimizing field coverage.

Understanding Sprayer Overlap and Its Impacts

Understanding sprayer overlap is crucial for optimizing pesticide and fertilizer application in precision agriculture, as excessive overlap leads to increased input costs and potential crop damage. Automatic Section Control (ASC) systems use GPS-guided technology to precisely shut off or reduce spray in overlapping areas, significantly reducing chemical waste and environmental impact compared to Manual Section Control (MSC). Studies show ASC can decrease overlap by up to 20%, enhancing field efficiency and promoting sustainable farming practices.

What is Manual Section Control?

Manual Section Control involves the operator manually turning sprayer sections on and off to avoid overlap during application. This method relies heavily on the operator's skill, visual judgment, and timely response to field boundaries or previously treated areas. While cost-effective, manual control can lead to inconsistent coverage and increased chemical usage compared to automatic systems.

How Automatic Section Control Operates

Automatic Section Control uses GPS technology and real-time field mapping to precisely manage sprayer nozzle activation, eliminating overlap and reducing chemical waste. Sensors detect the sprayer's position relative to previously treated areas, automatically turning off sections as the equipment passes over covered zones. This system enhances accuracy and efficiency by dynamically adjusting application based on field boundaries and obstacles without operator intervention.

Accuracy Comparison: Automatic vs Manual Section Control

Automatic Section Control systems utilize GPS technology and real-time field mapping to significantly reduce sprayer overlap, enhancing application accuracy by up to 95% compared to manual control. Manual Section Control often results in inconsistent spray patterns due to human error, leading to overlap and chemical waste. Studies show automatic control reduces input costs by minimizing over-application and improves crop yield through precise and uniform pesticide distribution.

Economic Benefits of Automatic Section Control

Automatic Section Control (ASC) significantly reduces overlap during spraying operations, leading to substantial savings on chemical inputs and fuel costs. By precisely activating and deactivating spray sections based on GPS data, ASC minimizes waste and increases application efficiency, resulting in improved crop yields and lower operational expenses. This technology enhances economic returns by optimizing resource use and reducing unnecessary reapplications, which manual section control often fails to achieve consistently.

Environmental Advantages: Reducing Chemical Waste

Automatic section control in precision agriculture significantly reduces chemical waste by precisely targeting spray applications, minimizing overlap compared to manual section control. This technology decreases the amount of herbicides, pesticides, and fertilizers used, thereby lowering runoff and environmental contamination. Reduced chemical waste leads to enhanced soil health and less impact on surrounding ecosystems.

Implementation Costs and Return on Investment

Automatic Section Control (ASC) significantly reduces sprayer overlap by using GPS and sensors to activate and deactivate spray nozzles precisely, minimizing input waste and crop damage. While ASC implementation requires higher initial costs, including hardware, software, and training, its ability to optimize chemical usage delivers measurable savings and improved yield potential. Manual Section Control, although less costly upfront, often leads to inconsistent application and increased operational expenses, resulting in a slower or lower return on investment compared to ASC systems.

User Experience: Learning Curve and Ease of Use

Automatic Section Control in precision agriculture significantly reduces the learning curve compared to manual section control by using GPS technology to automatically manage sprayer overlap, minimizing user input and errors. Users report enhanced ease of use due to real-time adjustments that eliminate the need for manual on-off switching, which is prone to human error and fatigue. This technology increases operational efficiency and consistency, making it accessible even to less experienced operators.

Future Trends in Sprayer Section Control Technology

Future trends in sprayer section control technology emphasize enhanced integration of AI and machine learning to improve automatic section control accuracy and efficiency. Advances in GPS precision and sensor fusion enable real-time adjustment of spraying zones, minimizing overlap and chemical waste more effectively than manual controls. Emerging technologies, such as drone-assisted monitoring and IoT connectivity, further optimize section control by providing comprehensive field data for smarter decision-making.

Related Important Terms

AutoBoom Section Mapping

Automatic Section Control, integrated with AutoBoom Section Mapping, significantly reduces sprayer overlap by precisely activating and deactivating boom sections based on GPS field boundaries and crop data. This contrasts with manual section control, which relies on operator timing and judgment, often leading to increased chemical waste and inconsistent application accuracy.

Rate-Controlled Section Shutdown

Rate-controlled section shutdown in automatic section control systems significantly reduces sprayer overlap by precisely halting spray application when sections enter previously treated zones, enhancing chemical use efficiency and minimizing environmental impact. Manual section control often results in human error and delayed response, leading to increased overlap and wasted inputs compared to the accuracy and timeliness of automated systems.

Section-by-Section Variable Application

Automatic Section Control (ASC) in precision agriculture significantly reduces sprayer overlap by enabling section-by-section variable application, improving input efficiency and minimizing environmental impact. Manual section control lacks the real-time responsiveness and accuracy of ASC, often resulting in over-application and increased operational costs.

GNSS-Guided Section Actuation

GNSS-guided automatic section control for sprayers significantly reduces overlap by precisely actuating spray sections based on real-time GPS positioning, enhancing application accuracy compared to manual control methods. This technology optimizes input usage, minimizes environmental impact, and increases operational efficiency in precision agriculture.

Turn Compensation Algorithms

Turn compensation algorithms in automatic section control systems significantly reduce sprayer overlap by adjusting spray sections based on precise vehicle turning radius and speed data, enhancing field coverage accuracy. Manual section control lacks real-time turn compensation, often resulting in inconsistent overlap and increased chemical waste during curved field operations.

ISOBUS Section Control Integration

ISOBUS Section Control integration enables automatic sprayer section control, significantly reducing overlap by synchronizing with GPS data to activate or deactivate spray sections precisely over targeted areas. Compared to manual section control, this technology enhances efficiency, minimizes chemical waste, and improves crop health through consistent application across variable field conditions.

Section Boundary Buffer Zones

Automatic Section Control (ASC) significantly reduces sprayer overlap by dynamically adjusting spray sections based on GPS-guided boundary data, minimizing the need for extensive section boundary buffer zones and enhancing application precision. In contrast, Manual Section Control relies on operator judgment to manage buffer zones, often resulting in inconsistent overlap reduction and increased chemical waste.

Prescription-Based Section Modulation

Prescription-based section modulation in automatic section control systems significantly reduces sprayer overlap by dynamically adjusting spray sections according to GPS and field prescription maps. This technology enhances input efficiency and lowers environmental impact compared to manual section control, which relies on operator judgment and often results in inconsistent overlaps.

Swath Overlap Analytics

Automatic Section Control systems utilize GPS-guided swath overlap analytics to minimize redundant spraying, enhancing resource efficiency and reducing environmental impact compared to Manual Section Control. By dynamically adjusting spray sections based on precise field mapping, these systems ensure accurate coverage, lower chemical usage, and improve overall crop health.

Smart Nozzle Individualization

Automatic Section Control with smart nozzle individualization optimizes sprayer overlap reduction by adjusting spray patterns in real-time, reducing chemical waste and environmental impact. Manual Section Control lacks precision, often causing overlap or missed areas, leading to uneven application and increased costs.

Automatic Section Control vs Manual Section Control for Sprayer Overlap Reduction Infographic

agridif.com

agridif.com