Acid treatment effectively reduces microbial growth on sericulture pets by lowering pH levels, creating an inhospitable environment for pathogens. Ultra-violet treatment sterilizes surfaces and larvae by disrupting microbial DNA, offering a chemical-free method that limits resistance development. Choosing between acid and ultra-violet treatment depends on factors like cost, environmental impact, and target pathogen sensitivity in sericulture disease prevention.

Table of Comparison

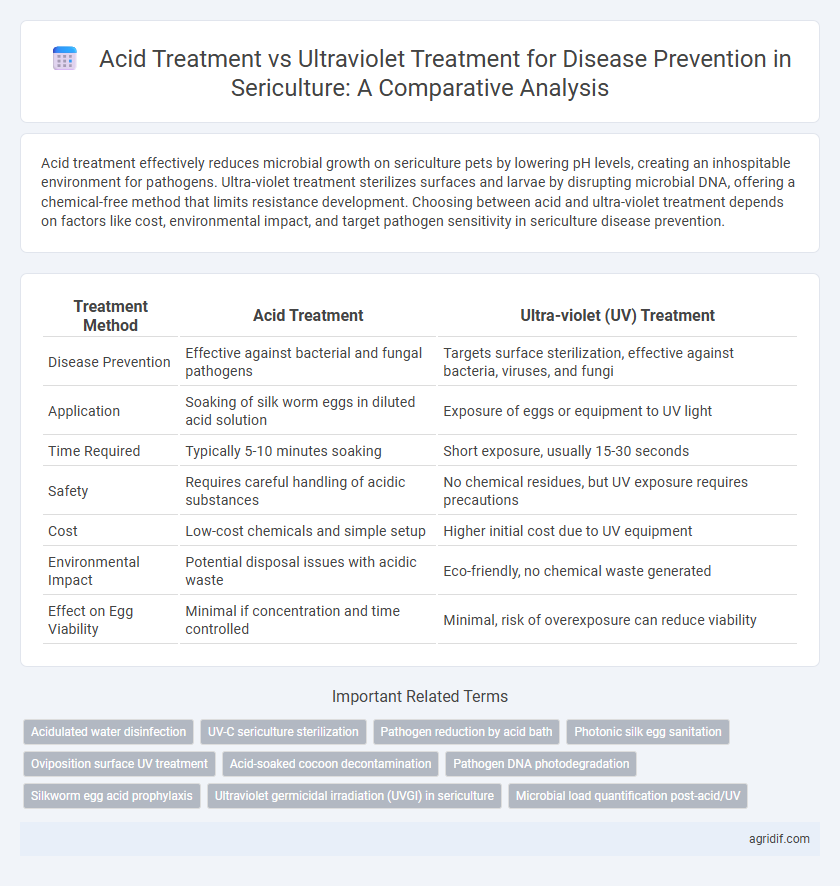

| Treatment Method | Acid Treatment | Ultra-violet (UV) Treatment |

|---|---|---|

| Disease Prevention | Effective against bacterial and fungal pathogens | Targets surface sterilization, effective against bacteria, viruses, and fungi |

| Application | Soaking of silk worm eggs in diluted acid solution | Exposure of eggs or equipment to UV light |

| Time Required | Typically 5-10 minutes soaking | Short exposure, usually 15-30 seconds |

| Safety | Requires careful handling of acidic substances | No chemical residues, but UV exposure requires precautions |

| Cost | Low-cost chemicals and simple setup | Higher initial cost due to UV equipment |

| Environmental Impact | Potential disposal issues with acidic waste | Eco-friendly, no chemical waste generated |

| Effect on Egg Viability | Minimal if concentration and time controlled | Minimal, risk of overexposure can reduce viability |

Introduction to Disease Prevention in Sericulture

Acid treatment and ultra-violet (UV) treatment are critical methods for disease prevention in sericulture, targeting the control of pathogens that affect silkworm health and cocoon quality. Acid treatment involves using diluted acids to disinfect eggs, effectively reducing fungal and bacterial contamination before hatching. UV treatment employs ultraviolet light to eliminate microbial spores on silkworm eggs and rearing environments, offering a chemical-free alternative with minimal residue risks.

Overview of Acid Treatment in Sericulture

Acid treatment in sericulture involves the application of dilute organic or inorganic acids to control microbial infections affecting silkworms, especially targeting bacterial and fungal pathogens. This method enhances larval immunity by altering the pH on the silkworm's surface and feed, reducing disease outbreaks effectively. Compared to ultraviolet treatment, acid treatment is cost-effective, simple to administer, and provides targeted pathogen suppression critical for maintaining healthy sericulture crops.

Mechanism of Acid Treatment for Pathogen Control

Acid treatment in sericulture involves applying a dilute acidic solution to silkworm eggs to inhibit the development of pathogenic microorganisms by lowering the pH environment, which disrupts microbial cell membrane integrity and enzyme function. This acidic environment prevents fungal and bacterial spore germination, thus reducing infection rates during the critical hatching phase. Compared to ultraviolet treatment, acid treatment offers a chemical barrier that ensures prolonged pathogen inhibition without direct exposure to radiation.

Ultra-violet Treatment: Principles and Applications

Ultra-violet (UV) treatment in sericulture uses germicidal UV-C rays to inactivate harmful pathogens on silkworm eggs and rearing environments by disrupting microbial DNA. This method offers a non-chemical, residue-free approach to disease prevention, enhancing silkworm health and cocoon quality without compromising egg viability. UV treatment technology is widely applied in hatcheries for disinfecting equipment and rearing trays, significantly reducing bacterial and viral outbreaks in sericulture farms.

Efficacy Comparison: Acid vs Ultra-violet Treatments

Acid treatment and ultra-violet (UV) treatment are both effective methods for disease prevention in sericulture, targeting pathogens on mulberry leaves and silkworm eggs. Acid treatments maintain a high efficacy rate by lowering the pH to inhibit fungal and bacterial growth, while UV treatment leverages germicidal radiation to destroy microorganisms without chemical residues. Studies indicate UV treatment offers rapid sterilization with minimal environmental impact, whereas acid treatment provides longer-lasting pathogen suppression but requires careful handling to avoid leaf damage.

Impact on Silkworm Health and Cocoon Yield

Acid treatment effectively controls bacterial and fungal infections in sericulture, promoting healthier silkworm growth and improving cocoon yield by reducing mortality rates. Ultra-violet treatment offers a non-chemical method that sterilizes rearing environments, minimizing pathogen presence without chemical residues, thus supporting optimal silkworm vitality and steady cocoon production. Studies indicate that combining mild acid treatment with UV sterilization can synergistically enhance silkworm health outcomes and maximize silk yield.

Environmental and Safety Considerations

Acid treatment in sericulture effectively controls fungal and bacterial infections but poses environmental risks due to chemical runoff and potential soil acidification. Ultra-violet treatment offers a non-chemical alternative that reduces pathogen load without introducing harmful residues, thus minimizing ecological impact and improving operator safety. The choice between these methods hinges on balancing disease control effectiveness with sustainable environmental practices and worker health protection.

Economic Analysis of Both Treatments

Acid treatment offers a cost-effective solution for sericulture disease prevention, requiring low-cost reagents and minimal equipment investment, making it accessible for small-scale farmers. Ultra-violet (UV) treatment, while involving higher initial equipment costs and energy consumption, reduces chemical use and lowers long-term environmental and health-related expenses. An economic analysis reveals that acid treatment minimizes upfront costs, but UV treatment may provide greater savings over time through improved disease control efficiency and reduced reliance on chemicals.

Practical Recommendations for Sericulturists

Acid treatment effectively controls fungal contaminants on silkworm eggs by lowering pH and inhibiting microbial growth, making it a cost-efficient method for sericulturists in resource-limited settings. Ultra-violet (UV) treatment offers a non-chemical, eco-friendly approach that sterilizes eggs and rearing environments by disrupting microbial DNA, reducing the risk of chemical residues. For practical disease prevention, sericulturists should select acid treatment for small-scale operations requiring simplicity, while adopting UV treatment in industrial setups prioritizing sustainability and minimized chemical use.

Future Trends in Disease Prevention Technologies

Acid treatment and ultraviolet (UV) treatment both serve critical roles in sericulture disease prevention, with UV treatment emerging as a more sustainable and precise technology due to its ability to target specific pathogens without chemical residues. Future trends indicate a shift towards integrating UV treatment with advanced sensor technologies and AI-driven monitoring systems to enhance efficacy and real-time disease detection. Innovations in nanotechnology-based UV delivery and eco-friendly acid formulations also promise to reduce environmental impact while improving silkworm health management.

Related Important Terms

Acidulated water disinfection

Acidulated water disinfection in sericulture effectively reduces microbial load on mulberry leaves, enhancing silkworm health by preventing bacterial and fungal infections. Compared to ultraviolet treatment, acid treatment penetrates biofilms and leaf surfaces more thoroughly, offering prolonged antimicrobial effects essential for disease control in sericulture.

UV-C sericulture sterilization

UV-C treatment in sericulture offers effective sterilization by disrupting the DNA of pathogens, significantly reducing microbial contamination on silkworm eggs and rearing environments. Compared to acid treatment, UV-C sterilization is chemical-free, eco-friendly, and prevents resistance development in silk-producing fungi and bacteria, promoting healthier silkworm growth and enhanced silk yield.

Pathogen reduction by acid bath

Acid treatment significantly reduces pathogens by altering the pH environment, effectively inhibiting bacterial and fungal growth on silkworm eggs during sericulture. This method offers a reliable pathogen reduction compared to ultraviolet treatment, which primarily targets surface microorganisms but may not penetrate deeply or affect all pathogen types.

Photonic silk egg sanitation

Acid treatment effectively sanitizes photonic silk eggs by lowering surface pH, inhibiting microbial growth without damaging the eggshell structure, while ultra-violet treatment utilizes germicidal wavelengths to disrupt the DNA of pathogens on egg surfaces, ensuring disease prevention in sericulture. Comparative studies highlight that ultra-violet treatment offers non-chemical sterilization with minimal residue, whereas acid treatment provides longer-lasting antimicrobial effects critical in large-scale silk moth rearing.

Oviposition surface UV treatment

Ultra-violet treatment of the oviposition surface effectively inhibits fungal and bacterial growth on silkworm eggs, offering a non-chemical alternative to acid treatment that minimizes residue and environmental impact. Studies demonstrate UV treatment enhances egg hatchability rates by maintaining surface sterility without compromising egg viability, positioning it as a sustainable method for disease prevention in sericulture.

Acid-soaked cocoon decontamination

Acid-soaked cocoon decontamination effectively inhibits bacterial and fungal pathogens, enhancing silk fiber quality by reducing microbial contamination during sericulture. Compared to ultraviolet treatment, acid treatment provides deeper penetration and longer-lasting antimicrobial protection, ensuring higher cocoon sterilization efficiency.

Pathogen DNA photodegradation

Acid treatment in sericulture primarily denatures pathogen proteins, whereas ultraviolet (UV) treatment targets pathogen DNA photodegradation, effectively disrupting microbial replication and preventing disease outbreaks. UV-induced DNA damage impairs pathogen survival more directly, offering a potent, chemical-free method for enhancing silkworm health and cocoon quality.

Silkworm egg acid prophylaxis

Silkworm egg acid prophylaxis involves immersing eggs in a weak acid solution, commonly hydrochloric acid, to eliminate bacterial and fungal pathogens, enhancing hatchability and larval health in sericulture. Ultra-violet treatment exposes eggs to controlled UV light, effectively reducing surface microbial load without chemical residues, although acid treatment remains preferred for its proven efficacy in preventing common silkworm diseases like grasserie and muscardine.

Ultraviolet germicidal irradiation (UVGI) in sericulture

Ultraviolet germicidal irradiation (UVGI) offers an effective non-chemical method for disease prevention in sericulture by disrupting the DNA of pathogens such as bacteria and fungi on mulberry leaves and silkworm eggs, thereby reducing the spread of infections like bacterial flacherie and fungal diseases. Compared to acid treatment, UVGI minimizes chemical residues and environmental impact while providing rapid disinfection and enhanced protection for silkworm health and cocoon quality.

Microbial load quantification post-acid/UV

Microbial load quantification post-acid treatment in sericulture shows a significant reduction in bacterial and fungal populations on silkworm rearing substrates compared to untreated controls. Ultra-violet (UV) treatment further decreases microbial contamination by effectively inactivating pathogens on surfaces, with quantitative assays indicating a greater log reduction in total viable counts than acid treatment alone.

Acid treatment vs Ultra-violet treatment for disease prevention Infographic

agridif.com

agridif.com