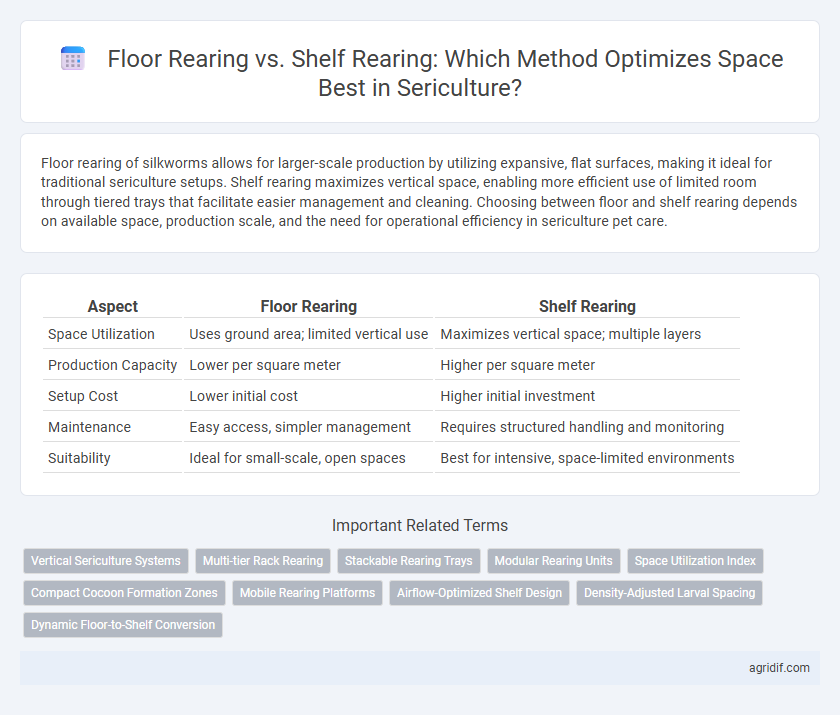

Floor rearing of silkworms allows for larger-scale production by utilizing expansive, flat surfaces, making it ideal for traditional sericulture setups. Shelf rearing maximizes vertical space, enabling more efficient use of limited room through tiered trays that facilitate easier management and cleaning. Choosing between floor and shelf rearing depends on available space, production scale, and the need for operational efficiency in sericulture pet care.

Table of Comparison

| Aspect | Floor Rearing | Shelf Rearing |

|---|---|---|

| Space Utilization | Uses ground area; limited vertical use | Maximizes vertical space; multiple layers |

| Production Capacity | Lower per square meter | Higher per square meter |

| Setup Cost | Lower initial cost | Higher initial investment |

| Maintenance | Easy access, simpler management | Requires structured handling and monitoring |

| Suitability | Ideal for small-scale, open spaces | Best for intensive, space-limited environments |

Introduction to Space Optimization in Sericulture

Floor rearing in sericulture utilizes ground-level space, allowing larvae to spread over a larger area, which can lead to increased airflow and easier waste management. Shelf rearing maximizes vertical space by stacking trays or racks, significantly enhancing the number of larvae per unit area and improving space efficiency in limited environments. Comparing these methods highlights the importance of selecting an appropriate rearing system to optimize space use and boost silk production in controlled settings.

Overview of Floor Rearing Method

The floor rearing method in sericulture involves placing silkworm trays directly on the ground, maximizing vertical space utilization in traditional settings. This technique allows for higher air circulation and easy maintenance but requires more floor area compared to shelf rearing systems. Floor rearing is preferred for large-scale operations where ample space is available, ensuring optimal growth conditions for silkworms.

Overview of Shelf Rearing Method

Shelf rearing in sericulture involves cultivating silkworms on vertically arranged trays, maximizing the use of limited space compared to traditional floor rearing. This method enhances air circulation, reduces disease spread, and facilitates easier management of larvae, leading to increased productivity per unit area. The shelf rearing system is particularly advantageous in urban sericulture settings where spatial constraints demand efficient resource utilization.

Comparison of Space Utilization Efficiency

Floor rearing in sericulture maximizes vertical space by spreading silkworm trays across a wide surface area, allowing for easier management but demanding more floor space. Shelf rearing optimizes space utilization by stacking trays vertically, significantly increasing the number of silkworms in a limited area and improving throughput without expanding the facility footprint. Shelf rearing demonstrates higher space utilization efficiency, making it suitable for commercial sericulture operations aiming to enhance productivity in confined environments.

Labor Requirements: Floor vs Shelf Rearing

Shelf rearing in sericulture significantly reduces labor requirements compared to traditional floor rearing by allowing easier access and organized space management for silkworm cultivation. The vertical arrangement in shelf rearing optimizes workspace, minimizes bending and physical strain for workers, and facilitates simultaneous monitoring of multiple silkworm trays. In contrast, floor rearing demands more labor-intensive handling due to limited space and the need for frequent repositioning and cleaning of silkworm beds.

Impact on Silkworm Health and Growth

Floor rearing provides ample space for silkworms to move freely, promoting better ventilation and reducing stress, which enhances their growth and overall health. Shelf rearing optimizes vertical space, allowing higher density cultivation but may increase the risk of disease transmission due to limited air circulation. Proper management of both methods is crucial to balance space efficiency with maintaining silkworm vitality and maximizing silk yield.

Cost Analysis: Setup and Maintenance

Floor rearing in sericulture generally demands higher initial setup costs due to extensive space requirements and infrastructure such as ventilation and sanitation systems, while shelf rearing optimizes vertical space, reducing land footprint and lowering construction expenses. Maintenance costs are typically higher for floor rearing because of increased labor for cleaning and disease control, whereas shelf rearing benefits from easier access and streamlined management, leading to reduced operational expenses. Cost analysis reveals shelf rearing as a more economical choice for maximizing limited space without compromising silkworm health and productivity.

Productivity Outcomes and Yield

Floor rearing in sericulture typically offers higher productivity outcomes due to better air circulation and natural microclimate conditions that promote robust silkworm growth, resulting in increased cocoon yield per unit area. Shelf rearing optimizes vertical space, allowing for greater larval density and efficient use of limited floor space, which can enhance yield in constrained environments but may require precise environmental control to maintain productivity. Balancing floor rearing's natural growth advantages with shelf rearing's space-saving benefits can lead to optimized overall yield and efficient resource utilization in sericulture operations.

Suitability for Small vs Large-Scale Sericulture

Floor rearing maximizes space utilization in small-scale sericulture by allowing efficient placement of trays on the ground, facilitating easy access and maintenance in limited areas. Shelf rearing optimizes vertical space, making it highly suitable for large-scale sericulture operations that require high-density silkworm cultivation within compact footprints. Both methods cater to different scale needs, with floor rearing favored for simplicity and shelf rearing preferred for maximizing productivity in industrial sericulture facilities.

Conclusion: Selecting the Optimal Rearing Method

Floor rearing offers extensive space utilization suitable for large-scale sericulture but requires higher maintenance and labor costs, while shelf rearing maximizes vertical space, enabling higher cocoon density per square meter with reduced footprint and improved environmental control. Optimal rearing method selection depends on farm size, available infrastructure, and resource allocation, where shelf rearing benefits urban or limited-space operations, whereas floor rearing suits expansive, traditional setups. Evaluating factors such as economic feasibility, yield output, and operational efficiency ensures maximum productivity in sericulture practices.

Related Important Terms

Vertical Sericulture Systems

Vertical sericulture systems utilizing shelf rearing optimize space by enabling multiple layers of silkworm trays, significantly increasing production per square meter compared to traditional floor rearing. Shelf rearing enhances microclimate control and eases larval management, leading to improved silk yield and reduced contamination risks in limited spatial environments.

Multi-tier Rack Rearing

Multi-tier rack rearing in sericulture maximizes space efficiency by utilizing vertical layers, significantly increasing cocoon yield per square meter compared to traditional floor rearing methods. This vertically integrated approach enhances larval rearing density while facilitating better air circulation and hygiene management, thereby optimizing both productivity and resource utilization.

Stackable Rearing Trays

Stackable rearing trays in shelf rearing maximize space utilization by allowing multiple layers of silkworm trays, significantly increasing production capacity within a limited area compared to traditional floor rearing methods. This vertical stacking system improves airflow and ease of management, optimizing silkworm growth environments while reducing the overall footprint of the sericulture facility.

Modular Rearing Units

Modular Rearing Units designed for shelf rearing maximize space efficiency by utilizing vertical space, allowing multiple trays to be stacked and increasing the larval rearing capacity within a limited footprint. In contrast, floor rearing occupies more ground area and offers less scalability, making shelf rearing the preferred method in modern sericulture for optimized space utilization and improved operational control.

Space Utilization Index

Floor rearing in sericulture offers a higher Space Utilization Index (SUI) by maximizing vertical and horizontal space for silkworm trays, whereas shelf rearing improves airflow and accessibility but often results in lower overall SUI due to fixed shelf dimensions. Optimizing space through floor rearing can enhance larval density per unit area, leading to more efficient silk yield in constrained environments.

Compact Cocoon Formation Zones

Shelf rearing enhances space optimization by creating compact cocoon formation zones with multiple layers, significantly increasing the usable rearing area compared to traditional floor rearing. This vertical arrangement reduces spatial footprint while maintaining optimal environmental conditions for silkworm growth and cocoon quality.

Mobile Rearing Platforms

Floor rearing in sericulture offers extensive space utilization by allowing silkworms to spread across larger horizontal surfaces, whereas shelf rearing maximizes vertical space through multi-tiered setups. Mobile rearing platforms enhance space optimization by enabling easy movement and reconfiguration of trays, increasing airflow and improving silkworm growth conditions within confined environments.

Airflow-Optimized Shelf Design

Shelf rearing in sericulture maximizes space efficiency by utilizing vertical airflow-optimized designs that enhance ventilation and temperature control, crucial for healthy silkworm development. Compared to floor rearing, this method reduces overcrowding and improves air circulation, minimizing disease risk and promoting consistent growth.

Density-Adjusted Larval Spacing

Floor rearing allows for higher Density-Adjusted Larval Spacing by providing a larger surface area for larvae to feed and grow, optimizing space utilization in sericulture. Shelf rearing, despite its vertical stacking advantage, often limits larval spacing due to confinement, potentially reducing overall larval density and growth efficiency.

Dynamic Floor-to-Shelf Conversion

Dynamic floor-to-shelf conversion in sericulture maximizes space utilization by allowing flexible adjustments between floor and shelf rearing systems based on larval growth stages and rearing density. This adaptability enhances feeding efficiency and environmental control while optimizing limited cultivation areas for increased silk production.

Floor rearing vs Shelf rearing for space optimization Infographic

agridif.com

agridif.com