Denier and Tex are both units used to measure silk filament thickness in sericulture, with Denier representing the weight in grams of 9,000 meters of silk fiber and Tex indicating the weight in grams of 1,000 meters. Denier is commonly preferred in the textile industry for finer gradations, while Tex provides a straightforward metric measurement ideal for comparing fiber thicknesses globally. Understanding the difference between Denier and Tex helps silk farmers and manufacturers accurately assess filament quality and uniformity for pet silk products.

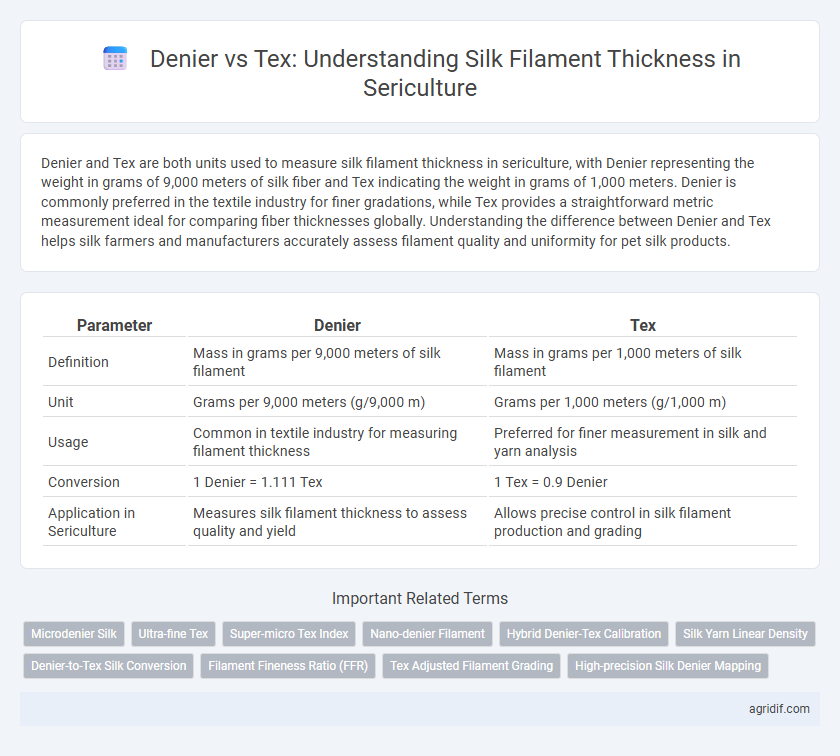

Table of Comparison

| Parameter | Denier | Tex |

|---|---|---|

| Definition | Mass in grams per 9,000 meters of silk filament | Mass in grams per 1,000 meters of silk filament |

| Unit | Grams per 9,000 meters (g/9,000 m) | Grams per 1,000 meters (g/1,000 m) |

| Usage | Common in textile industry for measuring filament thickness | Preferred for finer measurement in silk and yarn analysis |

| Conversion | 1 Denier = 1.111 Tex | 1 Tex = 0.9 Denier |

| Application in Sericulture | Measures silk filament thickness to assess quality and yield | Allows precise control in silk filament production and grading |

Understanding Silk Filament Thickness: Denier vs Tex

Silk filament thickness is commonly measured using Denier and Tex, two units that quantify fiber fineness for sericulture applications. Denier represents the weight in grams of 9,000 meters of fiber, making it ideal for comparing silk filaments' thickness at finer scales, while Tex measures the weight per 1,000 meters, providing a broader gauge suitable for industrial silk processing. Understanding the differences between Denier and Tex is crucial for optimizing silk filament quality, influencing fabric texture, strength, and end-use performance in textile manufacturing.

Key Differences Between Denier and Tex in Sericulture

Denier measures the mass in grams of 9,000 meters of silk filament, emphasizing fiber fineness, while Tex quantifies the mass in grams of 1,000 meters, providing a more precise measurement for thicker strands. In sericulture, Denier is commonly used to classify silk filament thickness for textiles, whereas Tex is preferred in industrial applications requiring exact yarn weight control. Understanding these differences aids in selecting the appropriate silk filament standard for quality and performance optimization in silk production.

Why Filament Thickness Matters in Silk Quality

Filament thickness, measured in denier or tex, directly influences silk quality by determining the fabric's strength, texture, and luster. Denier quantifies the mass in grams per 9,000 meters, while tex measures grams per 1,000 meters, with finer filaments yielding smoother, more lustrous silk ideal for luxury textiles. Consistent filament thickness ensures uniformity in silk fabric, affecting durability and the overall aesthetic appeal crucial for high-end sericulture products.

Denier Explained: Definition and Calculation for Silk

Denier is a unit of measurement that defines the thickness of silk filament by quantifying the mass in grams of 9,000 meters of fiber, with lower denier values indicating finer, more delicate silk threads. Calculating denier involves weighing a specified length of silk filament and applying the formula: Denier = (mass in grams / length in meters) x 9,000, facilitating standardization across sericulture products. Compared to Tex, which measures fiber mass per 1,000 meters, denier offers a more precise scale tailored for fine silk filament classification and quality assessment in textile manufacturing.

Tex: The Metric Alternative to Denier in Silk Measurement

Tex is a metric unit measuring the linear mass density of silk filaments, defined as grams per 1000 meters, providing a precise alternative to Denier, which is based on grams per 9000 meters. Unlike Denier, Tex enables standardized silk thickness comparison across international sericulture markets, facilitating consistent quality control and product specification. Utilizing Tex supports scientific research and industrial applications by aligning silk filament measurements with global textile metrics.

Comparing Denier and Tex: Which Is Better for Silk Assessment?

Denier and Tex are both units measuring the thickness of silk filaments, with Denier representing the weight in grams of 9,000 meters of silk and Tex indicating grams per 1,000 meters. Denier is widely used in the textile industry for finer filaments, providing precise control over lightweight silk products, while Tex offers a more absolute measure suitable for heavier, coarser silk yarns. For silk assessment, Denier is generally preferred due to its sensitivity to fine filament variations, critical for evaluating high-quality silk softness and delicacy.

Standard Ranges of Denier and Tex in Commercial Silk

Standard commercial silk filament thickness typically ranges from 10 to 30 denier, reflecting finer threads used in high-quality silk textiles. In Tex units, this corresponds approximately to 11 to 33, illustrating the direct relationship where Tex equals grams per 1,000 meters of fiber. These standardized ranges ensure consistent fabric strength and smoothness essential for luxury silk production and precise industrial applications.

Impact of Denier and Tex on Silk Fabric Properties

Denier and Tex are key units measuring silk filament thickness, directly influencing fabric texture and durability in sericulture. Higher Denier and Tex values correlate with thicker, stronger silk fibers, resulting in heavier, more robust fabrics suitable for upholstery or outerwear. Conversely, lower Denier and Tex produce finer, softer silk ideal for delicate garments like scarves or lingerie, affecting drape and sheen.

Choosing the Right Measurement: Denier vs Tex in Silk Production

Denier and Tex are both units used to measure silk filament thickness, critical for determining fabric weight and feel in sericulture. Denier measures the mass in grams per 9,000 meters of filament, making it ideal for finer silk threads, while Tex measures grams per 1,000 meters, often preferred for coarser filaments or industrial silk applications. Selecting the appropriate measurement depends on the silk's end use, as Denier offers finer granularity for delicate textiles whereas Tex provides easier calculations for larger scale production and quality control.

Future Trends: Evolving Standards in Silk Filament Thickness

Future trends in sericulture emphasize the shift from traditional denier measurements to the adoption of tex units for silk filament thickness, driven by global industry standardization and precision demands. Tex offers a more direct indication of linear density, aligning with advancements in silk processing technology and quality control. This evolution supports enhanced consistency in filament production, catering to high-performance textile applications and innovative silk blends.

Related Important Terms

Microdenier Silk

Microdenier silk filaments, characterized by their extremely fine diameter, are often measured using denier and tex units, where denier indicates the weight in grams per 9,000 meters and tex represents grams per 1,000 meters. Compared to standard silk fibers, microdenier silk exhibits superior softness and lightweight properties due to its lower denier values, making it ideal for high-end textile applications requiring delicate and smooth fabrics.

Ultra-fine Tex

Ultra-fine Tex measures silk filament thickness by grams per 1,000 meters, providing precise control in sericulture for producing fine, lightweight silk fibers. Compared to Denier, which counts grams per 9,000 meters, Ultra-fine Tex offers greater sensitivity in assessing filament fineness, essential for high-quality silk production.

Super-micro Tex Index

The Super-micro Tex Index measures silk filament thickness by quantifying the weight in grams per 1,000 meters of fiber, offering higher precision than Denier, which is based on grams per 9,000 meters. This finer metric enables sericulturists to optimize silk quality and production by accurately assessing the ultra-fine microstructure of silk threads crucial for luxury textiles.

Nano-denier Filament

Nano-denier filaments in sericulture represent a breakthrough in silk filament thickness measurement, where denier quantifies the mass in grams per 9,000 meters of filament, offering a finer scale compared to tex, which measures grams per 1,000 meters. The ultra-fine nano-denier filaments, significantly thinner than conventional silk strands, enhance fabric softness, strength, and lightweight properties, elevating luxury textile manufacturing standards.

Hybrid Denier-Tex Calibration

Hybrid Denier-Tex Calibration combines the advantages of denier and tex units to measure silk filament thickness, providing precise control over silk quality by accurately correlating fiber fineness with weight per unit length. This method enhances consistency in sericulture by optimizing filament uniformity, critical for superior silk fabric production and textile performance.

Silk Yarn Linear Density

Silk yarn linear density is commonly measured using denier and tex units, where denier represents the mass in grams per 9,000 meters of filament and tex indicates grams per 1,000 meters, making tex a larger scale than denier for assessing silk filament thickness. Accurate understanding of these measurements allows sericulture professionals to standardize silk quality, optimize weaving processes, and ensure consistent fabric performance.

Denier-to-Tex Silk Conversion

Denier and Tex are both units used to measure silk filament thickness, with Denier representing the mass in grams per 9,000 meters and Tex representing the mass in grams per 1,000 meters of fiber. The Denier-to-Tex conversion is calculated by dividing the Denier value by 9, or multiplying Tex by 9, providing an essential metric for comparing silk filament fineness in sericulture quality assessments.

Filament Fineness Ratio (FFR)

Denier and Tex are units measuring silk filament thickness, with Denier representing grams per 9,000 meters and Tex indicating grams per 1,000 meters, both crucial for determining filament fineness ratio (FFR). Filament Fineness Ratio (FFR) is the quotient of filament linear density and filament diameter, influencing silk's texture and strength by correlating filament fineness with its physical properties.

Tex Adjusted Filament Grading

Tex Adjusted Filament Grading offers a more precise evaluation of silk filament thickness by measuring mass per 1,000 meters, unlike Denier which measures mass per 9,000 meters, allowing finer differentiation in silk quality and texture. This method enhances consistency in lightweight silk classification and improves grading accuracy for sericulture production standards.

High-precision Silk Denier Mapping

Silk filament thickness is measured in denier and tex, with denier representing the mass in grams per 9,000 meters and tex indicating grams per 1,000 meters, both crucial for high-precision silk denier mapping used in quality control and material specification. Advanced imaging and analytical techniques enable detailed denier mapping, allowing for consistent silk filament thickness assessment which enhances fabric uniformity and performance in sericulture applications.

Denier vs Tex for silk filament thickness Infographic

agridif.com

agridif.com