Direct sun drying of silkworm cocoons accelerates moisture removal but risks over-drying, which can degrade silk quality and weaken fibers. Shade drying offers a gentler approach, preserving the natural moisture balance and maintaining cocoon integrity crucial for high-quality silk production. Choosing the right drying method directly influences the durability and hue of the silk, impacting overall sericulture success.

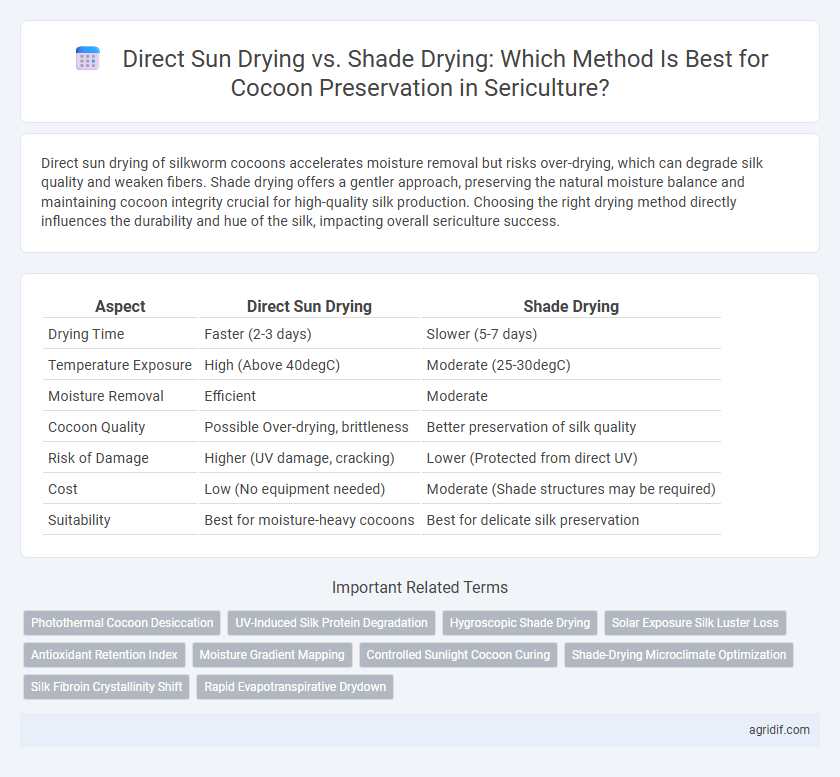

Table of Comparison

| Aspect | Direct Sun Drying | Shade Drying |

|---|---|---|

| Drying Time | Faster (2-3 days) | Slower (5-7 days) |

| Temperature Exposure | High (Above 40degC) | Moderate (25-30degC) |

| Moisture Removal | Efficient | Moderate |

| Cocoon Quality | Possible Over-drying, brittleness | Better preservation of silk quality |

| Risk of Damage | Higher (UV damage, cracking) | Lower (Protected from direct UV) |

| Cost | Low (No equipment needed) | Moderate (Shade structures may be required) |

| Suitability | Best for moisture-heavy cocoons | Best for delicate silk preservation |

Introduction to Cocoon Preservation in Sericulture

Cocoon preservation is crucial in sericulture to maintain the quality and viability of silk fibers before reeling. Direct sun drying rapidly reduces moisture content but can cause brittleness and color fading, negatively affecting silk quality. Shade drying offers a controlled environment that preserves cocoon integrity and prevents damage from excessive heat and UV exposure, ensuring higher silk yield.

Importance of Drying Methods in Cocoon Quality

Direct sun drying accelerates moisture removal from silkworm cocoons, reducing the risk of fungal growth and ensuring better preservation of silk fibroin integrity. Shade drying, while slower, maintains optimal temperature and humidity levels, preventing excessive brittleness and preserving cocoon elasticity essential for quality silk reeling. Selecting the appropriate drying method directly influences cocoon longevity, silk fiber strength, and overall silk production efficiency in sericulture.

Overview of Direct Sun Drying Techniques

Direct sun drying techniques for cocoon preservation involve spreading freshly harvested cocoons on clean, elevated platforms exposed to full sunlight, which accelerates moisture evaporation and prevents fungal growth. This method relies on natural solar radiation, utilizing intensity levels around 500-700 W/m2 during peak hours to achieve rapid drying within 3-5 hours, minimizing the risk of cocoon damage. Maintaining proper aeration and turning the cocoons periodically ensures uniform drying and preserves silk quality by reducing discoloration and filament breakage.

Shade Drying Methods for Silkworm Cocoons

Shade drying methods for silkworm cocoons involve drying in a controlled environment protected from direct sunlight, which preserves the cocoon's protein integrity and prevents brittleness. This technique maintains optimal moisture levels, reducing the risk of damage and ensuring better quality silk yield during reeling. Shade drying is especially effective in humid regions, as it prevents rapid dehydration and fungal growth, promoting healthier cocoon preservation.

Impact of Drying Methods on Cocoon Moisture Content

Direct sun drying significantly reduces cocoon moisture content more rapidly, enhancing preservation by minimizing fungal growth and decay risks. Shade drying maintains higher moisture levels, preserving delicate silk fibers but extending drying time and increasing susceptibility to microbial damage. Optimal moisture control through drying method selection directly influences cocoon quality and silk yield in sericulture.

Effects on Silk Filament Quality: Sun vs Shade

Direct sun drying of cocoons accelerates moisture removal but can cause protein denaturation in silk fibroin, leading to reduced filament strength and elasticity. Shade drying preserves the natural amino acid structure, maintaining superior silk filament tensile properties and luster. Optimal silk filament quality is typically achieved with controlled shade drying, minimizing exposure to UV radiation and excessive heat.

Time Efficiency: Comparing Drying Durations

Direct sun drying of cocoons typically takes 4 to 6 hours to reduce moisture content effectively, accelerating the processing time significantly compared to shade drying, which can require up to 24 hours. The faster drying duration in direct sunlight helps minimize the risk of fungal growth and preserves silk quality by preventing prolonged exposure to humidity. Time-efficient drying methods optimize the overall sericulture production cycle, enhancing productivity and silk yield.

Risk Factors: Pest, Mold, and Contamination

Direct sun drying of cocoons exposes them to higher risks of pest infestation and mold growth due to fluctuating moisture levels and intense heat, which can compromise cocoon quality. Shade drying offers a controlled environment that reduces contamination risks by maintaining consistent humidity and preventing direct exposure to pests and airborne pollutants. Effective drying methods directly influence cocoon preservation, impacting silk yield and fiber integrity in sericulture.

Economic Considerations in Drying Method Selection

Direct sun drying of cocoons reduces energy costs and accelerates the drying process, leading to increased daily throughput and faster market readiness. Shade drying, while less energy-intensive in terms of heat stress, often requires extended drying periods, raising labor costs and storage needs. Economic evaluation favors direct sun drying in regions with abundant sunlight, but shade drying may minimize quality loss, impacting long-term silk value and market price.

Recommendations for Optimal Cocoon Preservation

For optimal cocoon preservation in sericulture, shade drying is recommended over direct sun drying due to its ability to maintain the structural integrity and moisture content of silk cocoons, reducing brittleness and color degradation. Controlled shade drying environments help preserve the fibroin proteins, essential for high-quality silk fiber extraction, thereby enhancing yarn strength and luster. Implementing shade drying under well-ventilated conditions effectively minimizes fungal growth and insect infestation, ensuring superior cocoon quality for subsequent processing.

Related Important Terms

Photothermal Cocoon Desiccation

Photothermal cocoon desiccation through direct sun drying accelerates moisture removal by harnessing high solar radiation and elevated temperatures, enhancing cocoon preservation efficiency. In contrast, shade drying offers a controlled environment that reduces thermal stress and preserves silk quality by minimizing photodegradation and excessive heat exposure.

UV-Induced Silk Protein Degradation

UV-induced silk protein degradation significantly accelerates during direct sun drying of cocoons, compromising silk fiber strength and quality by breaking down fibroin. Shade drying reduces exposure to harmful UV rays, preserving the molecular integrity of silk proteins and enhancing cocoon preservation for superior silk production.

Hygroscopic Shade Drying

Hygroscopic shade drying for cocoon preservation regulates moisture absorption by maintaining consistent humidity levels, preventing damage caused by rapid dehydration or excessive moisture. This method enhances silk quality by preserving fibroin protein structure, reducing brittleness compared to direct sun drying, which often leads to uneven drying and weakened fibers.

Solar Exposure Silk Luster Loss

Direct sun drying causes significant solar exposure leading to silk luster loss due to ultraviolet radiation damaging the fibroin proteins in the cocoon. Shade drying minimizes UV impact, preserving the natural sheen and strength of silk fibers, thereby maintaining higher quality cocoon preservation.

Antioxidant Retention Index

Direct sun drying of silk cocoons significantly reduces the Antioxidant Retention Index due to increased exposure to ultraviolet radiation and higher temperatures, leading to accelerated degradation of antioxidant compounds. In contrast, shade drying preserves a higher Antioxidant Retention Index by maintaining moderate temperature and minimizing photodegradation, thereby enhancing the overall quality and longevity of the cocoons.

Moisture Gradient Mapping

Moisture gradient mapping reveals that direct sun drying of cocoons accelerates moisture loss, enhancing preservation by reducing fungal growth risk but may cause uneven drying and structural damage. Shade drying maintains a more uniform moisture gradient, preserving cocoon integrity but increasing drying time and potential for microbial contamination.

Controlled Sunlight Cocoon Curing

Controlled sunlight cocoon curing optimizes sericulture by balancing temperature and UV exposure, enhancing silk quality and preventing damage caused by direct sun drying. Shade drying maintains moisture and reduces discoloration but may extend drying time, making controlled sunlight curing the preferred method for efficient cocoon preservation.

Shade-Drying Microclimate Optimization

Shade drying of silkworm cocoons ensures optimal preservation by maintaining stable temperature and humidity levels, preventing discoloration and quality degradation caused by direct sunlight. Controlling microclimate factors such as airflow, shading intensity, and moisture retention enhances silk filament strength and overall cocoon viability compared to direct sun drying.

Silk Fibroin Crystallinity Shift

Direct sun drying accelerates the dehydration of silk cocoons but induces a significant shift in silk fibroin crystallinity, leading to decreased mechanical strength and reduced fiber quality. Shade drying preserves fibroin's natural crystalline structure, maintaining optimal molecular alignment essential for high-quality silk production.

Rapid Evapotranspirative Drydown

Direct sun drying accelerates rapid evapotranspirative drydown by maximizing heat and airflow exposure, which reduces cocoon moisture content efficiently but risks fiber damage due to excessive temperature. Shade drying offers a controlled environment that slows evapotranspiration, preserving cocoon integrity and quality by preventing thermal stress and uneven drying during the preservation process.

Direct Sun Drying vs Shade Drying for Cocoon Preservation Infographic

agridif.com

agridif.com