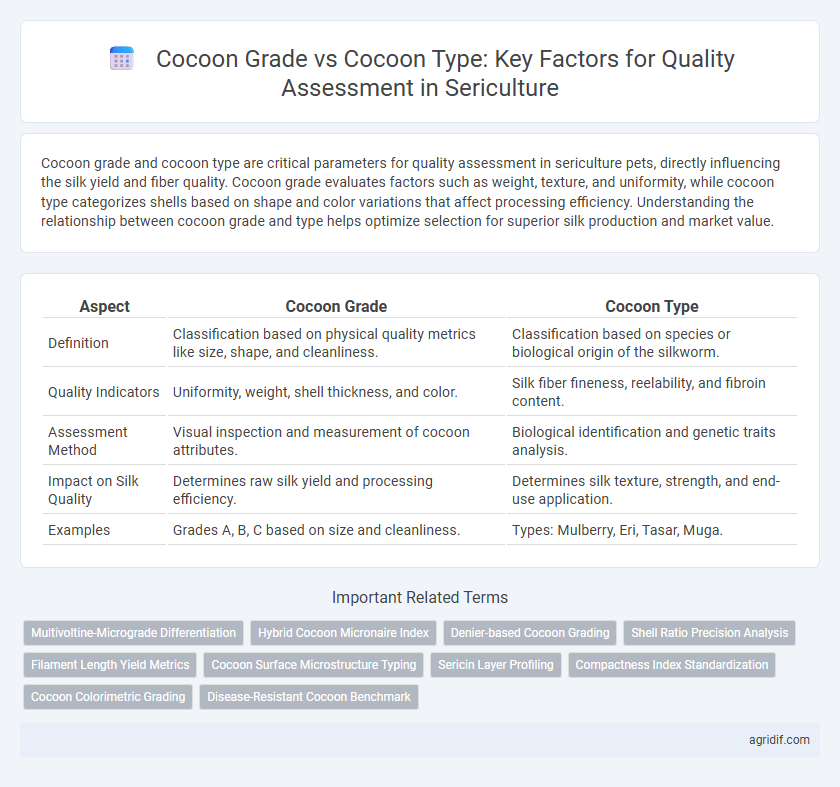

Cocoon grade and cocoon type are critical parameters for quality assessment in sericulture pets, directly influencing the silk yield and fiber quality. Cocoon grade evaluates factors such as weight, texture, and uniformity, while cocoon type categorizes shells based on shape and color variations that affect processing efficiency. Understanding the relationship between cocoon grade and type helps optimize selection for superior silk production and market value.

Table of Comparison

| Aspect | Cocoon Grade | Cocoon Type |

|---|---|---|

| Definition | Classification based on physical quality metrics like size, shape, and cleanliness. | Classification based on species or biological origin of the silkworm. |

| Quality Indicators | Uniformity, weight, shell thickness, and color. | Silk fiber fineness, reelability, and fibroin content. |

| Assessment Method | Visual inspection and measurement of cocoon attributes. | Biological identification and genetic traits analysis. |

| Impact on Silk Quality | Determines raw silk yield and processing efficiency. | Determines silk texture, strength, and end-use application. |

| Examples | Grades A, B, C based on size and cleanliness. | Types: Mulberry, Eri, Tasar, Muga. |

Understanding Cocoon Grades in Sericulture

Cocoon grade in sericulture is a critical quality assessment parameter based on parameters like cocoon weight, filament length, and reeling performance, which directly influence silk yield and quality. Cocoon types classify varieties according to shape, color, and texture, but cocoon grades provide a standardized metric essential for evaluating economic value and sericulture efficiency. Understanding cocoon grades helps farmers and silk producers optimize raw material selection, improve reeling outcomes, and enhance overall silk quality.

Defining Cocoon Types: Classification and Characteristics

Cocoon types in sericulture are classified primarily based on shape, size, and filament quality, with common categories including oval, round, and dumbbell-shaped cocoons. Each cocoon type exhibits distinct characteristics influencing silk yield and fiber texture, directly impacting the overall quality and market value of the silk produced. Accurate classification of cocoon types aids in selecting ideal breeding stock and optimizing silk reeling processes for superior quality assessment.

Key Differences Between Cocoon Grade and Cocoon Type

Cocoon grade primarily evaluates the quality based on parameters like size, weight, and shell percentage, reflecting the raw material's suitability for silk production. Cocoon type categorizes cocoons according to the species or variety of silkworm, which directly influences fiber characteristics such as texture and color. Understanding these distinctions is crucial for optimizing silk yield and ensuring consistent fabric quality in sericulture operations.

Criteria for Cocoon Grading: Quality Parameters

Cocoon grading in sericulture relies on specific quality parameters including shell weight, shell ratio, fiber length, and filament strength, which collectively determine the economic value of the cocoon. Cocoon grade assesses overall quality by integrating factors such as moisture content, color uniformity, and filament fineness, while cocoon type categorizes based on shape and texture variations relevant to silkworm species and rearing conditions. Accurate evaluation of these parameters ensures optimized silk yield and consistent production quality within sericulture operations.

Influencing Factors for Cocoon Type Selection

Cocoon grade and cocoon type are critical parameters in sericulture quality assessment, with cocoon type selection influenced by factors such as environmental conditions, silkworm breed, and rearing practices. Temperature, humidity, and leaf quality significantly affect the silk filament length and texture, thereby determining the suitable cocoon type for production. Selecting the optimal cocoon type ensures consistency in silk quality and enhances overall yield efficiency.

Impact of Grade vs Type on Silk Yield and Quality

Cocoon grade plays a critical role in determining silk yield, as higher-grade cocoons exhibit superior shell weight and filament length, directly enhancing silk productivity. Cocoon type influences fiber quality by affecting tensile strength and fiber elasticity, crucial parameters for fabric durability and texture. Optimal silk production requires balancing both cocoon grade and type, since grade predominantly impacts yield while type governs silk quality characteristics.

Methods for Assessing Cocoon Quality

Cocoon grade is determined by evaluating parameters such as filament length, weight, and color uniformity, while cocoon type categorizes the variations based on genetic and environmental factors influencing silk yield and texture. Methods for assessing cocoon quality include physical inspection, filament reeling tests, and microscopic analysis to measure fiber strength and elasticity. Advanced techniques like infrared spectroscopy and digital imaging enhance accuracy in differentiating between cocoon grades and types, optimizing sericulture production.

Role of Genetics and Rearing in Cocoon Grade and Type

Cocoon grade and cocoon type serve as crucial indicators for assessing the quality of silk production, deeply influenced by genetics and rearing practices in sericulture. Genetic factors determine the inherent traits of the silkworm strain, directly impacting cocoon uniformity, size, and filament quality, which define the cocoon grade. Meanwhile, optimized rearing conditions such as temperature, humidity, and nutrition modulate cocoon development, affecting cocoon type characteristics like shape and shell thickness, thereby collectively guiding the overall quality evaluation.

Market Implications: Pricing Based on Grade and Type

Cocoon grade significantly influences market pricing, with higher-grade cocoons fetching premium rates due to superior filament quality and uniformity, directly impacting silk fabric value. Cocoon type, categorized by factors like shape and color, affects buyer preference and specialized demand, thereby shaping niche market pricing strategies. Understanding the interplay between cocoon grade and type enables sericulture stakeholders to optimize revenue by targeting specific market segments and quality-conscious consumers.

Best Practices for Quality Assessment in Sericulture

Cocoon grade classification primarily evaluates physical and biochemical properties such as weight, silk filament length, and moisture content, which directly impact the silk yield and quality. Cocoon type categorization focuses on morphological characteristics including shape, color, and texture to determine suitability for specific silk varieties and end-use applications. Integrating both cocoon grade and type assessments ensures a comprehensive evaluation, enabling producers to maintain high-quality standards and maximize silk production efficiency.

Related Important Terms

Multivoltine-Micrograde Differentiation

Multivoltine cocoon quality assessment relies heavily on distinguishing between cocoon grade and cocoon type, with micrograde differentiation playing a crucial role in this process. Accurate classification of micrograde within multivoltine cocoons enhances silk yield predictions and directly impacts the efficiency of sericulture practices.

Hybrid Cocoon Micronaire Index

Cocoon grade classification evaluates physical traits such as size, weight, and shape, while cocoon type categorizes based on silk filament properties, both critical for assessing silk quality in sericulture. The Hybrid Cocoon Micronaire Index specifically measures fiber fineness and maturity, providing a precise indicator of silk quality that complements traditional grading and typing methods.

Denier-based Cocoon Grading

Cocoon grade, determined primarily by denier measurement, provides a precise quantification of silk filament thickness crucial for quality assessment in sericulture, whereas cocoon type categorizes cocoons based on morphological and species-specific traits. Denier-based cocoon grading offers standardized evaluation of silk yield and fiber consistency, directly impacting the commercial value and processing efficiency of raw silk.

Shell Ratio Precision Analysis

Cocoon grade directly influences shell ratio precision analysis by categorizing cocoons based on uniformity, cleanliness, and filament continuity, which are critical for accurate quality assessment in sericulture. Cocoon type, defined by species and rearing conditions, affects the physical and chemical properties of the silk but requires precise shell ratio metrics to differentiate quality levels within the graded categories.

Filament Length Yield Metrics

Cocoon grade directly influences filament length yield metrics by categorizing cocoons based on uniformity, size, and color, which correlate with filament quality and length consistency. Cocoon type, defined by species and morphological traits, affects yield variability and silk filament elasticity, crucial for optimizing sericulture productivity and end-product value.

Cocoon Surface Microstructure Typing

Cocoon surface microstructure typing provides precise differentiation between cocoon types by analyzing fiber arrangement, thickness, and surface texture, which directly influences silk quality and processing efficiency. Comparing cocoon grade versus cocoon type based on microstructural features enables more accurate quality assessment for sericulture, facilitating selection of superior raw material for high-grade silk production.

Sericin Layer Profiling

Cocoon grade classification emphasizes the overall physical quality and uniformity of the cocoon shell, while cocoon type categorizes based on genetic and morphological characteristics affecting silk yield and texture. Sericin layer profiling serves as a critical biochemical marker that enhances quality assessment by correlating sericin thickness and composition with cocoon grade, thereby improving selection accuracy for optimal sericulture production.

Compactness Index Standardization

Cocoon grade and cocoon type are critical parameters in sericulture quality assessment, with the Compactness Index serving as a standardized metric to evaluate fiber density and uniformity. Standardizing the Compactness Index enables precise differentiation between grades and types, ensuring consistent quality control and optimizing silk yield.

Cocoon Colorimetric Grading

Cocoon grade in sericulture refers to the classification based on filament length, twisting properties, and reelability, while cocoon type categorizes the physical characteristics, including shape and size. Cocoon colorimetric grading assesses quality by analyzing color parameters such as brightness, hue, and saturation, enabling precise evaluation of silk yield and dyeing potential.

Disease-Resistant Cocoon Benchmark

Cocoon grade classification based on factors such as size, weight, and shell ratio directly correlates with silk quality, whereas cocoon type categorizes morphological traits essential for identifying disease-resistant strains in sericulture. The Disease-Resistant Cocoon Benchmark prioritizes cocoon types exhibiting enhanced resistance to viral and bacterial infections, ensuring sustainable silk production through robust cocoon quality standards.

Cocoon grade vs Cocoon type for quality assessment Infographic

agridif.com

agridif.com