Field-based rearing of silkworms offers natural environmental conditions that promote healthier growth and can enhance silk quality, though it exposes larvae to weather fluctuations and predators. Indoor rearing provides controlled temperature, humidity, and hygiene, reducing risks of disease and allowing consistent production but may require higher initial investments and energy use. Selecting the optimal method depends on balancing environmental control with cost-efficiency and the desired silk yield in sericulture pet practices.

Table of Comparison

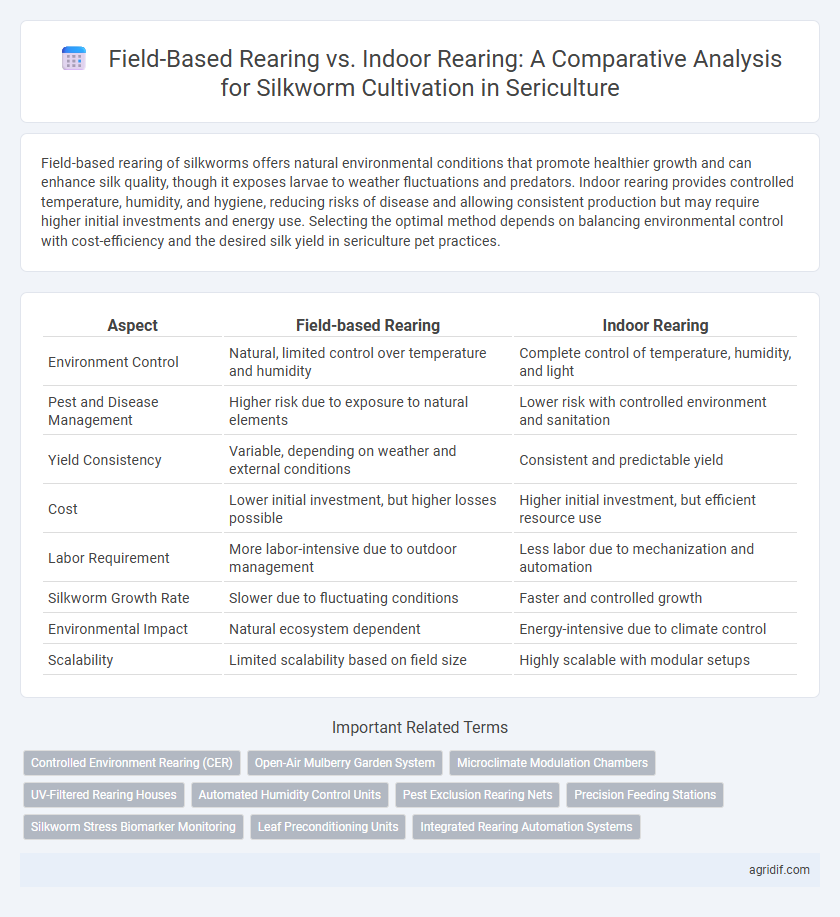

| Aspect | Field-based Rearing | Indoor Rearing |

|---|---|---|

| Environment Control | Natural, limited control over temperature and humidity | Complete control of temperature, humidity, and light |

| Pest and Disease Management | Higher risk due to exposure to natural elements | Lower risk with controlled environment and sanitation |

| Yield Consistency | Variable, depending on weather and external conditions | Consistent and predictable yield |

| Cost | Lower initial investment, but higher losses possible | Higher initial investment, but efficient resource use |

| Labor Requirement | More labor-intensive due to outdoor management | Less labor due to mechanization and automation |

| Silkworm Growth Rate | Slower due to fluctuating conditions | Faster and controlled growth |

| Environmental Impact | Natural ecosystem dependent | Energy-intensive due to climate control |

| Scalability | Limited scalability based on field size | Highly scalable with modular setups |

Introduction to Sericulture: Field-based vs Indoor Rearing

Field-based rearing of silkworms relies on natural environmental conditions, promoting cost-effective cultivation but exposing larvae to pests and weather fluctuations. Indoor rearing offers controlled temperature, humidity, and hygiene, ensuring higher survival rates and consistent silk quality, although it demands higher initial investment and infrastructure. Choosing between field-based and indoor rearing depends on regional climate, resource availability, and desired production scale in sericulture operations.

Environmental Requirements for Silkworm Rearing

Field-based rearing of silkworms demands specific environmental conditions such as moderate temperature (23-28degC), high humidity (70-85%), and ample fresh air circulation to ensure optimal larval growth and cocoon quality. Indoor rearing allows precise control over temperature, humidity, and light, reducing risks from pests and diseases while maintaining a sterile environment that promotes consistent silkworm development. Carefully managed environmental parameters in both methods are crucial for maximizing silk yield and quality in sericulture.

Space Utilization: Field-based vs Indoor Systems

Field-based sericulture requires extensive outdoor areas for mulberry cultivation and silkworm rearing, often constrained by environmental factors and seasonal variations. Indoor rearing systems optimize space utilization by enabling vertical stacking of trays and controlled density settings, maximizing production within limited areas. This spatial efficiency in indoor setups reduces land dependency and enhances year-round silkworm cultivation capacity.

Disease Management in Field and Indoor Rearing

Field-based sericulture exposes silkworms to natural environmental conditions, increasing vulnerability to pathogens like grasserie, flacherie, and muscardine diseases due to fluctuating humidity and temperature. Indoor rearing provides controlled environments that significantly reduce disease incidence by maintaining optimal temperature, humidity, and sanitation, facilitating early detection and treatment of infections. Implementing rigorous hygiene protocols and selective breeding in indoor settings enhances disease resistance and boosts overall silk productivity.

Labor and Cost Implications for Both Methods

Field-based rearing of silkworms generally involves lower initial infrastructure costs but demands higher and more variable labor inputs due to environmental monitoring and pest control. Indoor rearing, while capital-intensive with higher upfront expenses for controlled environments, reduces labor costs by enabling automation and streamlined management. Cost-effectiveness depends on scale and local labor rates, with indoor methods offering long-term savings through consistent production and minimized environmental risks.

Silkworm Growth Rates: Field vs Indoor Environments

Silkworm growth rates differ significantly between field-based and indoor rearing environments, with indoor conditions offering controlled temperature, humidity, and light that optimize larval development and reduce mortality. Field rearing exposes silkworms to fluctuating climatic conditions and natural predators, often resulting in slower growth and increased vulnerability to diseases. Studies indicate that indoor rearing can accelerate silkworm growth by up to 20%, enhancing cocoon quality and overall silk yield in sericulture operations.

Quality and Quantity of Silk Yield Comparison

Field-based rearing of silkworms often results in higher quantity of silk yield due to natural environmental conditions that promote robust larval growth, but it can also expose worms to pests and diseases that reduce quality. Indoor rearing provides controlled temperature, humidity, and hygiene, significantly enhancing the quality and uniformity of silk fibers by minimizing contamination and stress on silkworms. Comparatively, indoor rearing optimizes silk quality with consistent yield, while field-based methods may yield larger volumes at the risk of variable quality and higher loss rates.

Sustainability and Eco-Impact of Rearing Methods

Field-based rearing of silkworms relies on natural mulberry leaves and traditional open-air conditions, promoting biodiversity and minimizing energy consumption, which enhances sustainability. Indoor rearing offers controlled environments that reduce disease risk and resource wastage but often require artificial lighting and climate control, increasing energy use and ecological footprint. Evaluating eco-impact, field-based rearing supports ecosystem balance, while indoor methods necessitate sustainable energy solutions to mitigate environmental costs.

Technological Integration in Indoor and Field Rearing

Field-based rearing of silkworms relies on natural environmental conditions, making it susceptible to weather fluctuations and pests, whereas indoor rearing enables precise control of temperature, humidity, and light through advanced climate control systems. Integration of IoT sensors and automated feeding mechanisms in indoor rearing optimizes growth rates and disease management, significantly boosting cocoon yield and quality. Conversely, hybrid models incorporating remote monitoring technologies in field conditions enhance real-time data collection, improving pest control and environmental adaptation.

Future Trends and Recommendations in Silkworm Cultivation

Future trends in silkworm cultivation emphasize integrating advanced sensor technology and climate control systems to optimize indoor rearing conditions, enhancing larval growth rates and silk quality. Field-based rearing remains valuable for genetic diversity preservation, but scalable indoor facilities reduce disease outbreaks and environmental variability, ensuring consistent silk production. Recommendations include adopting hybrid models combining controlled indoor environments with field exposure to balance productivity and biodiversity in sustainable sericulture.

Related Important Terms

Controlled Environment Rearing (CER)

Controlled Environment Rearing (CER) offers precise regulation of temperature, humidity, and light, significantly enhancing silkworm growth and cocoon quality compared to traditional field-based methods. Indoor rearing under CER minimizes environmental fluctuations and pest exposure, leading to higher yield consistency and improved sericulture productivity.

Open-Air Mulberry Garden System

Field-based rearing of silkworms in open-air mulberry garden systems leverages natural environmental conditions, promoting healthier silkworm growth and higher cocoon yields through optimal temperature and humidity regulation. Unlike indoor rearing, this method reduces infrastructure costs and enhances mulberry leaf quality by allowing direct exposure to sunlight and natural air circulation, crucial for sericulture productivity.

Microclimate Modulation Chambers

Microclimate Modulation Chambers in silkworm cultivation provide precise control over temperature, humidity, and ventilation compared to traditional field-based rearing, significantly enhancing larval survival and silk quality. Indoor rearing using these chambers facilitates consistent microenvironmental conditions, reducing disease incidence and improving cocoon yield by up to 30% relative to outdoor methods influenced by variable weather.

UV-Filtered Rearing Houses

Field-based rearing exposes silkworms to natural environmental fluctuations, which can increase disease susceptibility and mortality rates, whereas indoor UV-filtered rearing houses provide controlled conditions that reduce ultraviolet radiation exposure, minimizing stress and promoting higher cocoon quality and yield. UV-filtered environments enhance larval growth by maintaining optimal temperature and humidity levels while preventing microbial growth, leading to more consistent silk production in sericulture.

Automated Humidity Control Units

Automated Humidity Control Units enhance indoor rearing of silkworms by maintaining optimal moisture levels, reducing disease risk and improving cocoon quality compared to unpredictable field-based conditions. Precise humidity regulation in controlled environments increases yield efficiency and ensures consistent silk fiber production critical for sericulture industry advancements.

Pest Exclusion Rearing Nets

Field-based rearing of silkworms exposes larvae to higher risks of pest infestation and environmental fluctuations, reducing cocoon quality and yield. Indoor rearing with pest exclusion rearing nets effectively minimizes pest access, ensures controlled microclimates, and enhances silkworm health and silk production efficiency.

Precision Feeding Stations

Precision feeding stations in silkworm cultivation enhance nutrient delivery accuracy, significantly improving growth rates and cocoon quality compared to traditional field-based rearing. Indoor rearing environments equipped with these stations optimize temperature, humidity, and feed consistency, reducing mortality while maximizing silk yield efficiency.

Silkworm Stress Biomarker Monitoring

Field-based rearing exposes silkworms to variable environmental factors such as fluctuating temperature and humidity, leading to elevated stress biomarker levels like heat shock proteins and antioxidant enzymes. Indoor rearing offers controlled conditions that minimize oxidative stress and physiological strain, enabling more precise monitoring of stress biomarkers for improved silkworm health and silk yield.

Leaf Preconditioning Units

Leaf Preconditioning Units optimize mulberry leaf freshness and nutrient content, enhancing silkworm growth in both field-based and indoor rearing systems. These units regulate temperature and humidity to maintain leaf quality, directly influencing larval development and cocoon yield in sericulture.

Integrated Rearing Automation Systems

Integrated Rearing Automation Systems optimize silkworm cultivation by combining field-based rearing's natural environmental benefits with controlled indoor rearing conditions, enhancing productivity and disease management. This hybrid approach uses sensors, climate control, and automated feeding mechanisms to maintain ideal temperature, humidity, and nutrition levels, resulting in higher silk yield and improved larval health.

Field-based rearing vs Indoor rearing for silkworm cultivation Infographic

agridif.com

agridif.com