Grainage seed, sourced directly from specialized seed production farms, ensures higher purity and superior genetic quality for silkworm egg production compared to commercial seed. Commercial seed, often mass-produced and distributed widely, may contain mixed breeds resulting in inconsistent hatching rates and lower silk yield. Selecting grainage seed improves silk quality and enhances the overall productivity of sericulture operations.

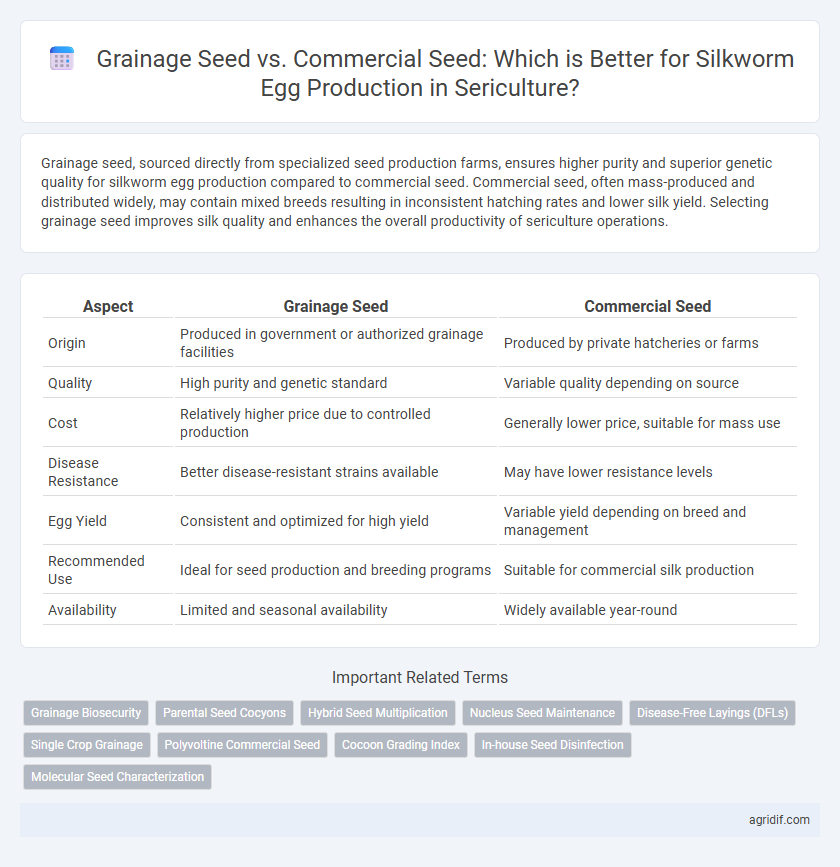

Table of Comparison

| Aspect | Grainage Seed | Commercial Seed |

|---|---|---|

| Origin | Produced in government or authorized grainage facilities | Produced by private hatcheries or farms |

| Quality | High purity and genetic standard | Variable quality depending on source |

| Cost | Relatively higher price due to controlled production | Generally lower price, suitable for mass use |

| Disease Resistance | Better disease-resistant strains available | May have lower resistance levels |

| Egg Yield | Consistent and optimized for high yield | Variable yield depending on breed and management |

| Recommended Use | Ideal for seed production and breeding programs | Suitable for commercial silk production |

| Availability | Limited and seasonal availability | Widely available year-round |

Introduction to Silkworm Seed Production

Silkworm seed production involves two primary types of seeds: grainage seed and commercial seed, each serving distinct purposes in sericulture. Grainage seed is produced under controlled conditions at specialized facilities to ensure high fertility, disease resistance, and genetic purity, making it ideal for sustaining silkworm rearing operations. Commercial seed, derived from grainage seed through farmers or sericulture farms, is distributed for large-scale silkworm cultivation to maximize cocoon yield and silk quality.

Understanding Grainage Seed in Sericulture

Grainage seed in sericulture refers to silkworm eggs produced through controlled breeding within specialized rearing units called grainages, ensuring superior genetic quality, hatchability, and disease resistance compared to commercial seed. These seeds enable consistent cocoon yield and enhance filament quality due to their genetic purity and optimized production conditions. Understanding the advantages of grainage seed over commercial seed is crucial for sustainable sericulture, maximizing silk productivity and economic returns.

What Are Commercial Seeds in Silkworm Rearing?

Commercial seeds in silkworm rearing refer to silkworm eggs produced under controlled conditions to ensure high fertility, disease resistance, and uniform larval growth. These eggs are typically sourced from certified grainage units with superior genetic stock, enabling consistent cocoon yield and quality. Commercial seeds significantly enhance productivity compared to local or unimproved varieties, supporting sustainable sericulture practices.

Genetic Purity: Grainage Seed vs Commercial Seed

Grainage seed maintains higher genetic purity due to controlled breeding and selection processes within dedicated seed production farms, ensuring consistency in silkworm egg quality and performance. Commercial seed often undergoes less rigorous genetic screening, potentially leading to heterogeneity and reduced hatchability rates. Superior genetic purity in grainage seed directly influences traits such as silk yield, disease resistance, and larval vigor in silkworm rearing.

Disease Resistance and Seed Source Selection

Grainage seed, produced under controlled hygienic conditions, exhibits superior disease resistance compared to commercial seed, making it ideal for high-quality silkworm egg production. Selecting seed from certified grainages ensures genetic purity and minimizes the risk of viral and bacterial infections such as grasserie and flacherie disease. In contrast, commercial seed, often sourced from multiple unverified suppliers, poses higher risks of contamination and inconsistent disease resistance, impacting overall sericulture productivity.

Yield Potential: Comparing Grainage and Commercial Seeds

Grainage seed exhibits a higher yield potential in silkworm egg production due to its controlled breeding and superior genetic quality, which enhances larval vitality and cocoon output. Commercial seeds, while more readily available and cost-effective, often show variable yield performance influenced by environmental factors and less rigorous genetic selection. Optimal sericulture practices recommend using grainage seed to maximize cocoon yield and silk quality, especially in large-scale or high-value production systems.

Cost Considerations in Seed Procurement

Grainage seed, produced under controlled hygienic conditions, often incurs higher initial costs due to quality assurance and disease management, ensuring superior egg viability and hatchability for silkworm production. Commercial seed, sourced from local farmers or small-scale breeders, tends to be more affordable but may pose risks of lower productivity and increased disease susceptibility, potentially leading to greater long-term expenses. Evaluating cost considerations in seed procurement involves balancing upfront investment in Grainage seed against the potential operational savings and yield consistency it offers over cheaper Commercial seed options.

Impact on Cocoon Quality and Productivity

Grainage seed, which is centrally produced under controlled hygienic conditions, ensures high genetic purity and disease resistance, directly enhancing cocoon quality and overall productivity in sericulture. In contrast, commercial seed often lacks uniformity and disease management, leading to variable cocoon traits and reduced silk yield. Using grainage seed consistently results in improved filament length, fiber strength, and cocoon weight, making it the preferred choice for optimizing silkworm egg production outcomes.

Suitability for Small and Large-Scale Farmers

Grainage seed, produced through controlled grainage methods, offers higher genetic purity and vigor, making it ideal for small-scale farmers aiming for quality improvement and consistency in silkworm egg production. Commercial seed, often mass-produced with less stringent selection, suits large-scale farmers who prioritize quantity and cost-efficiency over genetic uniformity. Choosing the appropriate seed type depends on the scale of operation, with grainage seeds enhancing yield reliability for boutique producers and commercial seeds facilitating large-volume silkworm rearing.

Best Practices for Seed Selection in Sericulture

Grainage seed, produced under controlled conditions in specialized seed-producing units, offers higher egg fertility and disease resistance compared to commercial seed, making it ideal for ensuring quality silkworm egg production. Selecting grainage seed enhances uniformity and hatchability rates, which are critical for maximizing cocoon yield and silk quality. Best practices involve sourcing grainage seed from certified centers while ensuring proper storage and timely incubation for optimal silkworm rearing outcomes.

Related Important Terms

Grainage Biosecurity

Grainage seed, produced under controlled, pathogen-free environments, ensures higher biosecurity levels by minimizing disease risks in silkworm egg production compared to commercial seed, which may carry latent infections due to less stringent quality controls. Enhanced biosecurity in grainage seed production directly improves larval viability and cocoon quality, crucial for sustainable sericulture outcomes.

Parental Seed Cocyons

Parental seed cocoons in grainage seed production ensure high genetic purity and disease resistance, leading to robust silkworm eggs with consistent quality. Commercial seed cocoons often prioritize quantity over pedigree, which can result in variable egg viability and reduced uniformity in silkworm rearing outcomes.

Hybrid Seed Multiplication

Grainage seed in hybrid seed multiplication ensures genetic purity and consistency crucial for high-yield silkworm egg production, while commercial seed, often derived from grainage stock, is tailored for mass rearing but may exhibit slight genetic variability. Utilizing grainage seed optimizes the hybrid vigor and silk quality by maintaining controlled breeding conditions essential for sericulture efficiency.

Nucleus Seed Maintenance

Grainage seed, maintained through rigorous selection and controlled breeding in nucleus seed programs, ensures high genetic purity and superior cocoon quality for silkworm egg production. This contrasts with commercial seed, which is mass-produced with less stringent quality controls, often leading to variability in silkworm performance and reduced overall yield.

Disease-Free Layings (DFLs)

Grainage seeds, produced under controlled conditions with strict disease monitoring, typically ensure a higher percentage of Disease-Free Layings (DFLs) compared to commercial seeds, which may carry a greater risk of silkworm diseases due to less rigorous screening. Using grainage seeds enhances silkworm egg production's quality and yield by minimizing disease-related losses and promoting healthier larvae development.

Single Crop Grainage

Single Crop Grainage prioritizes Grainage Seed for silkworm egg production due to its high hatchability and genetic purity, ensuring optimal larval vigor and cocoon yield; in contrast, Commercial Seed often shows reduced hatch rates and heterogeneity, leading to inconsistent crop performance. Utilizing Grainage Seed enhances sericulture productivity by maximizing uniformity and silk quality in a single cropping cycle.

Polyvoltine Commercial Seed

Polyvoltine commercial seed offers higher yield and disease resistance compared to traditional grainage seed, making it ideal for continuous silkworm egg production in tropical climates. Its genetic stability and optimized hatchability significantly enhance cocoon quality and overall sericulture profitability.

Cocoon Grading Index

Grainage seed, derived from controlled sericultural farms, typically exhibits a higher Cocoon Grading Index due to superior genetic purity and uniformity compared to commercial seed, which often includes mixed genetic lines leading to variable cocoon quality. The elevated Cocoon Grading Index in grainage seed directly enhances silk yield and filament length, making it preferable for optimized silkworm egg production and superior silk quality.

In-house Seed Disinfection

In-house seed disinfection enhances grainage seed quality by reducing pathogen load, ensuring higher hatchability and vigorous larval development compared to commercial seed. Effective sterilization protocols in grainage operations minimize microbial contamination, promoting improved silkworm egg productivity and overall sericulture sustainability.

Molecular Seed Characterization

Molecular seed characterization in sericulture distinguishes Grainage seed from commercial seed by analyzing genetic markers to ensure purity and vigor in silkworm egg production. This advanced technique enables precise identification of high-quality Grainage seed, enhancing disease resistance and silk yield compared to conventional commercial seed varieties.

Grainage Seed vs Commercial Seed for Silkworm Egg Production Infographic

agridif.com

agridif.com