Mountage offers a stable and straightforward framework for silkworm cocoon spinning, promoting natural silk thread formation by mimicking tree branches. Chandelier structures provide a multi-tiered design that maximizes space efficiency, allowing a higher density of silkworms to spin simultaneously. Choosing between mountage and chandelier setups depends on the scale of sericulture and the desired balance between ease of harvesting and space optimization.

Table of Comparison

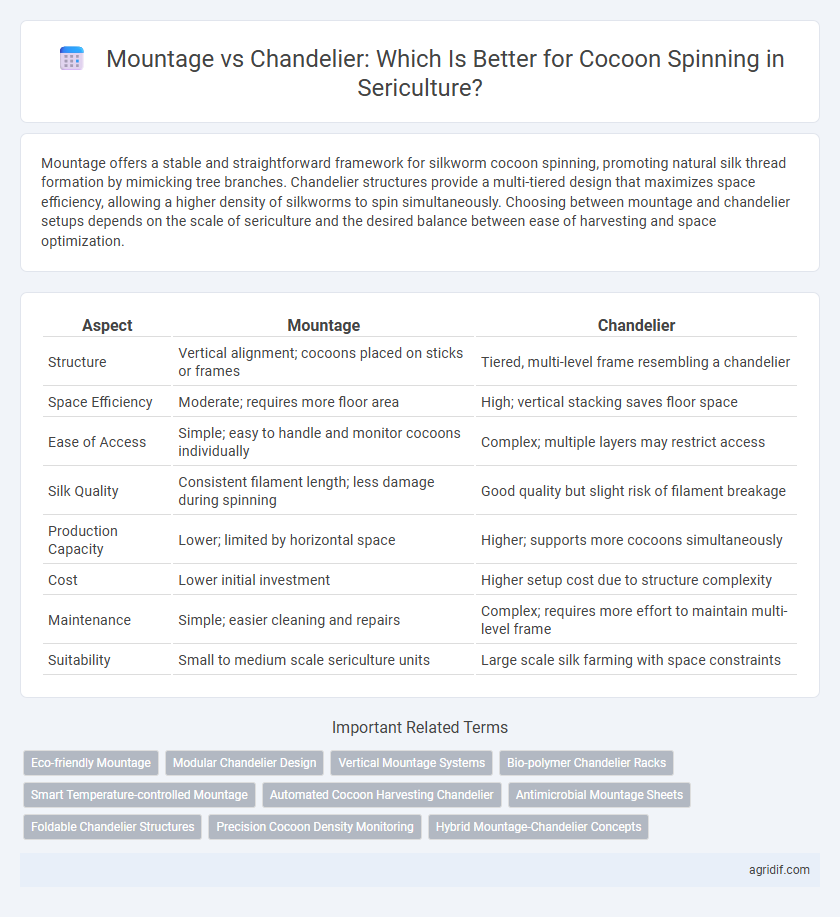

| Aspect | Mountage | Chandelier |

|---|---|---|

| Structure | Vertical alignment; cocoons placed on sticks or frames | Tiered, multi-level frame resembling a chandelier |

| Space Efficiency | Moderate; requires more floor area | High; vertical stacking saves floor space |

| Ease of Access | Simple; easy to handle and monitor cocoons individually | Complex; multiple layers may restrict access |

| Silk Quality | Consistent filament length; less damage during spinning | Good quality but slight risk of filament breakage |

| Production Capacity | Lower; limited by horizontal space | Higher; supports more cocoons simultaneously |

| Cost | Lower initial investment | Higher setup cost due to structure complexity |

| Maintenance | Simple; easier cleaning and repairs | Complex; requires more effort to maintain multi-level frame |

| Suitability | Small to medium scale sericulture units | Large scale silk farming with space constraints |

Introduction to Sericulture Cocoon Spinning Methods

Mountage cocoon spinning method involves training silkworms to spin cocoons on limited, structured frames, optimizing space and enhancing silk yield quality. Chandelier spinning utilizes hanging multi-branched frames allowing larger groups of silkworms to spin cocoons simultaneously, increasing production efficiency in sericulture farms. Both methods are fundamental for improved silk filament extraction, each suited to different scales and sericulture operational preferences.

Overview of Mountage and Chandelier Techniques

Mountage technique in sericulture involves arranging silkworm trays on multi-tiered racks, optimizing space and enhancing air circulation for uniform cocoon spinning. Chandelier technique uses hanging frames resembling chandeliers to suspend trays, allowing better light exposure and ease of handling during cocoon formation. Both methods aim to maximize cocoon quality and production efficiency by providing controlled environmental conditions tailored to silkworm behavior.

Structural Design: Mountage vs Chandelier

Mountage cocoon spinning structures feature a horizontal frame design that supports multiple silkworm trays, promoting uniform airflow and ease of maintenance. Chandelier systems employ a vertically suspended framework resembling a chandelier, optimizing space usage by allowing cocoons to hang in tiers, which enhances silk filament extraction. The structural design of mountage offers stability and scalability, while chandelier frameworks focus on maximizing vertical space efficiency and cocoon accessibility during the sericulture process.

Material Requirements and Setup

Mountage setups for cocoon spinning in sericulture demand minimal materials, primarily consisting of simple wooden frames or bamboo sticks, making them cost-effective and easy to assemble. In contrast, chandelier systems require more complex metal frameworks or plastic fixtures that support multiple spinning units simultaneously, increasing material costs and setup time. The choice between mountage and chandelier influences not only the scale of cocoon production but also the initial investment in infrastructure and maintenance.

Cocoon Quality: Effects of Spinning Devices

Mountage spinning devices provide a controlled environment that enhances cocoon quality by allowing uniform filament formation and reducing breakage during spinning. In contrast, chandelier systems often result in variable cocoon texture and increased filament damage due to less regulated spinning conditions. Optimizing device choice improves filament strength, cocoon uniformity, and overall silk yield in sericulture operations.

Space Utilization and Management

Mountage systems for cocoon spinning offer compact space utilization by arranging multiple frames vertically, maximizing production within limited areas typical of urban sericulture farms. Chandelier setups, while visually accessible for monitoring, spread horizontally and require larger floor space, potentially reducing overall density of cocoon production. Efficient management of mountage favors high-density output and streamlined maintenance, whereas chandelier configurations can facilitate easier individual frame inspection but at the cost of spatial efficiency.

Labor and Time Efficiency Comparison

Mountage systems for cocoon spinning demand higher initial labor input but significantly reduce total production time by enabling multiple silkworms to spin simultaneously in a controlled environment. Chandelier methods, while easier to set up and requiring less skilled labor, often lead to longer cocoon formation periods due to less optimal spacing and airflow. Evaluating labor hours per kilogram of silk produced reveals mountage offers superior time and labor efficiency, making it ideal for large-scale sericulture operations.

Cost Analysis: Initial and Maintenance Expenses

Mountage systems for cocoon spinning in sericulture typically incur lower initial costs due to simpler materials and construction compared to chandelier systems, which require more complex frameworks and higher-quality components. Maintenance expenses for mountage are also generally reduced, as its straightforward design minimizes repair needs and labor intensity, while chandeliers may demand regular upkeep to maintain structural integrity and functionality. Evaluating total cost of ownership reveals mountage as a cost-effective choice for small to medium-scale operations, whereas chandelier systems suit larger enterprises with higher budgets and scalability demands.

Common Challenges and Solutions

Mountage and chandelier systems both present challenges in maintaining consistent temperature and humidity crucial for optimal cocoon spinning in sericulture. Common issues include uneven airflow and space constraints, which can disrupt larval development and reduce cocoon quality. Solutions involve implementing controlled ventilation systems and adjustable frame spacing to ensure uniform environmental conditions and maximize silk yield.

Choosing the Right Method for Your Sericulture Farm

Mountage involves attaching cocoons onto frames, promoting uniform silk filament extraction and reducing filament breakage, while chandelier systems suspend cocoons individually, allowing better airflow and minimizing moisture accumulation. Selecting the appropriate method depends on farm size, labor availability, and climate conditions; mountage suits large-scale operations seeking efficiency, whereas chandeliers benefit small to medium farms aiming for quality and cocoon preservation. Understanding these differences optimizes silk yield and enhances sericulture farm profitability.

Related Important Terms

Eco-friendly Mountage

Eco-friendly Mountage techniques in sericulture offer a sustainable alternative to traditional Chandelier spinning methods by using biodegradable materials and reducing energy consumption, thereby minimizing environmental impact. This approach enhances cocoon quality and promotes eco-conscious silk production while supporting biodiversity and maintaining natural habitat integrity.

Modular Chandelier Design

Modular chandelier designs in sericulture offer flexible assembly and scalability for optimal cocoon spinning environments, enhancing airflow and space utilization compared to traditional mountage systems. Their adjustable configurations support uniform silk filament production by providing consistent support and ventilation, improving overall cocoon quality and yield.

Vertical Mountage Systems

Vertical Mountage Systems in sericulture offer a compact and efficient alternative to traditional chandelier setups by allowing cocoons to be arranged vertically, maximizing space utilization and improving airflow around the spinning cocoons. This configuration facilitates uniform silk filament extraction and reduces cocoon damage, enhancing overall silk yield and quality compared to the horizontally dispersed chandelier method.

Bio-polymer Chandelier Racks

Bio-polymer chandelier racks offer superior durability and eco-friendly benefits compared to traditional mountage systems in sericulture, enabling enhanced cocoon spinning efficiency by providing uniform spacing and optimal airflow. These racks reduce contamination risks and promote healthy silkworm development, improving overall silk yield and quality.

Smart Temperature-controlled Mountage

Smart temperature-controlled mountage systems enhance cocoon spinning efficiency by precisely regulating the microclimate, leading to optimized silk fiber quality and higher yield compared to traditional chandelier methods. This technology allows for consistent environmental stability, reducing larval stress and improving overall sericulture productivity.

Automated Cocoon Harvesting Chandelier

Automated cocoon harvesting chandeliers in sericulture enhance efficiency by allowing simultaneous spinning on multiple spinning frames, significantly increasing cocoon output compared to mountage, which involves manual, sequential cocoon spinning. The chandelier system integrates mechanized frame rotation and automated harvesting, optimizing silk filament quality while reducing labor intensity and time consumption in cocoon collection.

Antimicrobial Mountage Sheets

Antimicrobial mountage sheets provide superior hygiene control compared to chandelier systems by inhibiting microbial growth during cocoon spinning, significantly reducing contamination risks for silkworms. This innovative material enhances silk quality and increases yield by maintaining optimal cleanliness throughout the sericulture process.

Foldable Chandelier Structures

Foldable chandelier structures in sericulture offer enhanced flexibility and space efficiency for cocoon spinning compared to traditional mountage frames, enabling easier handling and optimized airflow around the cocoons. These designs contribute to improved silk fiber quality by providing uniform spinning environments and simplified maintenance during the silkworm development stages.

Precision Cocoon Density Monitoring

Mountage systems provide superior precision cocoon density monitoring through automated sensor integration, enabling real-time data collection and enhanced control over spinning parameters compared to traditional chandelier setups. This technological advancement leads to optimized cocoon uniformity and improved silk quality by maintaining consistent environmental conditions and minimizing human error.

Hybrid Mountage-Chandelier Concepts

Hybrid Mountage-Chandelier systems combine the structured framework of mountage with the vertical efficiency of chandelier designs to optimize cocoon spinning in sericulture. This integration enhances airflow, maximizes space utilization, and improves larval comfort, leading to higher silk yield and superior cocoon quality.

Mountage vs Chandelier for cocoon spinning Infographic

agridif.com

agridif.com