Hand spinning in sericulture allows for greater control over fiber thickness and quality, producing unique, artisanal silk threads prized for their texture and craftsmanship. Machine reeling offers faster, more efficient silk extraction with consistent fiber length and strength, suitable for large-scale production and commercial use. Choosing between hand spinning and machine reeling depends on the desired silk quality, production volume, and the balance between traditional techniques and industrial efficiency.

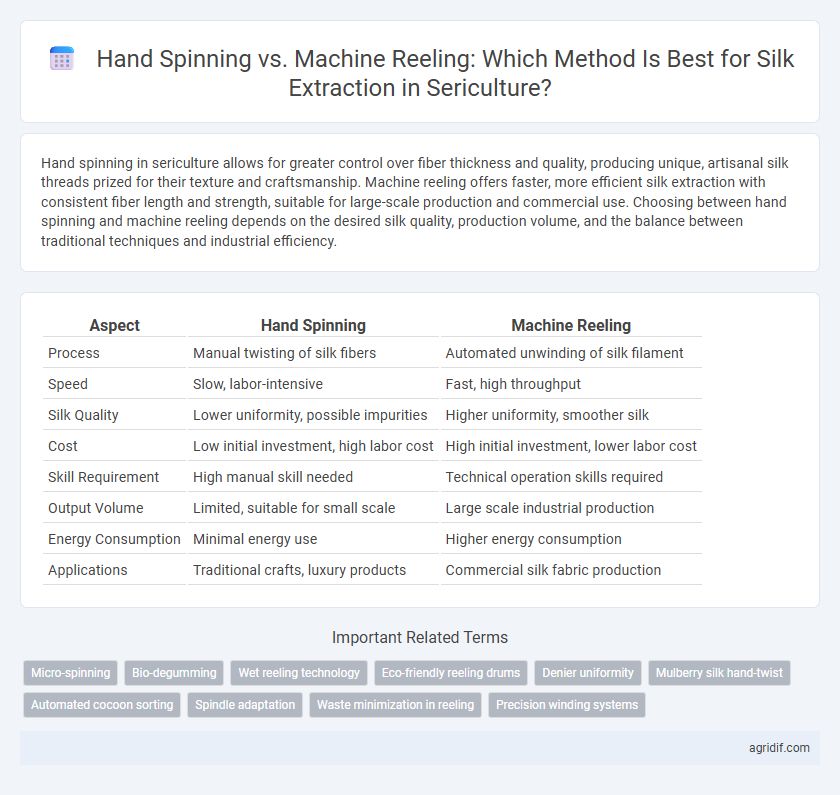

Table of Comparison

| Aspect | Hand Spinning | Machine Reeling |

|---|---|---|

| Process | Manual twisting of silk fibers | Automated unwinding of silk filament |

| Speed | Slow, labor-intensive | Fast, high throughput |

| Silk Quality | Lower uniformity, possible impurities | Higher uniformity, smoother silk |

| Cost | Low initial investment, high labor cost | High initial investment, lower labor cost |

| Skill Requirement | High manual skill needed | Technical operation skills required |

| Output Volume | Limited, suitable for small scale | Large scale industrial production |

| Energy Consumption | Minimal energy use | Higher energy consumption |

| Applications | Traditional crafts, luxury products | Commercial silk fabric production |

Introduction to Silk Extraction Methods

Hand spinning involves manually twisting silk fibers extracted from cocoons, preserving fiber length but limiting production speed and consistency. Machine reeling automates the unwinding of silk filaments from cocoons, enhancing efficiency, uniformity, and large-scale output. Both methods play crucial roles in sericulture, balancing traditional craftsmanship with industrial demands.

Overview of Hand Spinning in Sericulture

Hand spinning in sericulture involves manually twisting silk filaments drawn from cocoons into yarn, preserving the natural texture and strength of raw silk fibers. This traditional method allows artisans to maintain greater control over thread thickness and quality, often resulting in unique, high-value silk products with artisan appeal. Despite slower production rates compared to machine reeling, hand spinning supports sustainable practices and retains cultural heritage in silk fabric creation.

Machine Reeling: Principles and Process

Machine reeling in sericulture involves the mechanical extraction of silk fibers from silk cocoons, utilizing precision-driven reels to unwind continuous silk filaments. This process relies on controlled temperature and moisture to soften sericin, facilitating smooth filament separation and minimizing breakage. Advanced reeling machines enhance efficiency and consistency, producing high-quality silk threads essential for textile manufacturing.

Quality of Silk: Hand Spun vs Machine Reeled

Hand spinning preserves the natural texture and strength of silk fibers, resulting in a high-quality, lustrous silk prized for its softness and durability. Machine reeling, while faster, can sometimes cause fiber breakage and reduce the overall quality due to mechanical tension and heat exposure. Quality assessments often favor hand-spun silk for luxury textiles, highlighting its superior sheen and elasticity compared to machine-reeled silk.

Efficiency and Productivity Comparison

Hand spinning in sericulture yields lower silk output due to slower fiber extraction and greater manual labor, limiting overall efficiency. Machine reeling significantly enhances productivity by automating silk thread extraction, producing consistent, high-quality filaments at faster rates. Industrial-scale operations favor machine reeling for superior efficiency, reduced waste, and the ability to meet large market demands.

Labor and Skill Requirements

Hand spinning silk requires highly skilled artisans who meticulously twist raw silk fibers by hand, demanding intensive labor and precision to maintain fiber quality. In contrast, machine reeling automates the extraction process, significantly reducing manual labor and allowing for higher consistency with less specialized skill. While hand spinning preserves traditional craftsmanship and produces unique silk textures, machine reeling enhances efficiency and scalability in sericulture production.

Impact on Sericulture Farmers’ Livelihoods

Hand spinning in sericulture allows farmers to maintain traditional skills and secure higher profit margins by producing artisanal silk, though it is labor-intensive and less efficient. Machine reeling increases silk extraction efficiency and output, enabling scalability but often leads to reduced employment opportunities for small-scale farmers. The balance between these methods significantly influences farmers' income stability and the socio-economic dynamics within sericulture communities.

Environmental Considerations of Each Method

Hand spinning in sericulture produces minimal waste and consumes significantly less energy than machine reeling, making it an environmentally sustainable choice. Machine reeling, although efficient and capable of higher silk extraction rates, often relies on electric power and may generate more waste due to processing speed and technological complexity. The ecological footprint of hand spinning is considerably lower, contributing less to pollution and resource depletion compared to industrial reeling processes.

Economic Analysis: Costs and Profits

Hand spinning silk involves lower initial investment but results in higher labor costs and lower output compared to machine reeling, which requires significant capital expenditure on equipment but enhances efficiency and yields higher quality silk. Machine reeling reduces extraction time and labor dependency, increasing silk filament length and tensile strength, which commands better market prices and greater profit margins. An economic analysis reveals that while hand spinning remains viable for small-scale or artisanal producers, mechanized reeling offers superior long-term profitability and scalability in commercial sericulture operations.

Innovations and Future Trends in Silk Extraction

Innovations in silk extraction have focused on enhancing efficiency and quality through machine reeling, which offers higher speed and consistent thread thickness compared to traditional hand spinning. Advances in automated reeling technology integrate robotics and sensor systems to minimize silk waste and improve filament integrity, enabling large-scale production to meet growing demand. Future trends emphasize eco-friendly processes, incorporating bio-based lubricants and AI-driven monitoring to optimize silk yield while reducing environmental impact in sericulture.

Related Important Terms

Micro-spinning

Hand spinning in sericulture preserves the delicate quality of silk fibers, enabling precise control over thread thickness and texture, which enhances the final fabric's softness and durability. Micro-spinning technology streamlines silk extraction by mechanically reeling cocoons at a controlled pace, boosting efficiency and consistency while maintaining the silk's natural luster and strength.

Bio-degumming

Hand spinning in sericulture allows for delicate handling of silk fibers, preserving natural sericin content that facilitates bio-degumming through enzymatic treatments, resulting in eco-friendly silk extraction. Machine reeling offers higher efficiency and uniformity but often requires chemical degumming to remove sericin, which can reduce the bio-degradability of silk and increase environmental impact.

Wet reeling technology

Wet reeling technology enhances silk extraction by preserving fibroin integrity and increasing filament length, resulting in higher-quality silk compared to traditional hand spinning. Machine reeling offers consistency and efficiency, producing uniform silk threads with reduced labor and waste.

Eco-friendly reeling drums

Eco-friendly reeling drums in hand spinning minimize energy consumption and reduce environmental impact compared to conventional machine reeling, promoting sustainable silk extraction with lower carbon emissions. These innovative drums support artisanal silk production by preserving fiber quality while enhancing recyclability and biodegradability in sericulture practices.

Denier uniformity

Hand spinning in sericulture often results in variable denier uniformity due to manual tension control, causing inconsistencies in silk thread thickness. Machine reeling provides superior denier uniformity by maintaining consistent tension and speed, ensuring a more homogeneous silk filament ideal for high-quality textile production.

Mulberry silk hand-twist

Hand spinning Mulberry silk, known as hand-twist, preserves the fiber's natural sheen and strength by allowing meticulous control over tension and twist, resulting in a finer, more durable thread ideal for luxury textiles. Machine reeling speeds up extraction but often compromises the silk's delicate filament integrity, making hand spinning preferable for high-quality Mulberry silk production.

Automated cocoon sorting

Automated cocoon sorting enhances efficiency in machine reeling by precisely categorizing cocoons based on quality and size, reducing human error compared to hand spinning methods. This technology streamlines silk extraction, resulting in consistent fiber yield and superior silk quality for industrial production.

Spindle adaptation

Hand spinning in sericulture allows spindles to adapt flexibly to variable fiber thickness and length, ensuring delicate handling and preservation of silk quality. Machine reeling, however, relies on standardized spindle mechanisms optimized for speed and uniform tension, potentially compromising the natural variability essential for premium silk texture.

Waste minimization in reeling

Hand spinning of silk typically results in higher waste due to the manual extraction process that often breaks or shortens silk fibers, reducing yield efficiency. Machine reeling significantly minimizes waste by providing consistent, controlled tension and speed, enabling smooth extraction of long, continuous silk filaments that maximize raw silk recovery.

Precision winding systems

Precision winding systems in hand spinning offer meticulous control over silk thread tension and quality, enhancing the uniformity of the final product. Machine reeling, equipped with advanced precision winding technology, enables higher efficiency and consistent silk extraction, minimizing thread breakage and optimizing fiber alignment for superior fabric strength.

Hand spinning vs Machine reeling for silk extraction Infographic

agridif.com

agridif.com