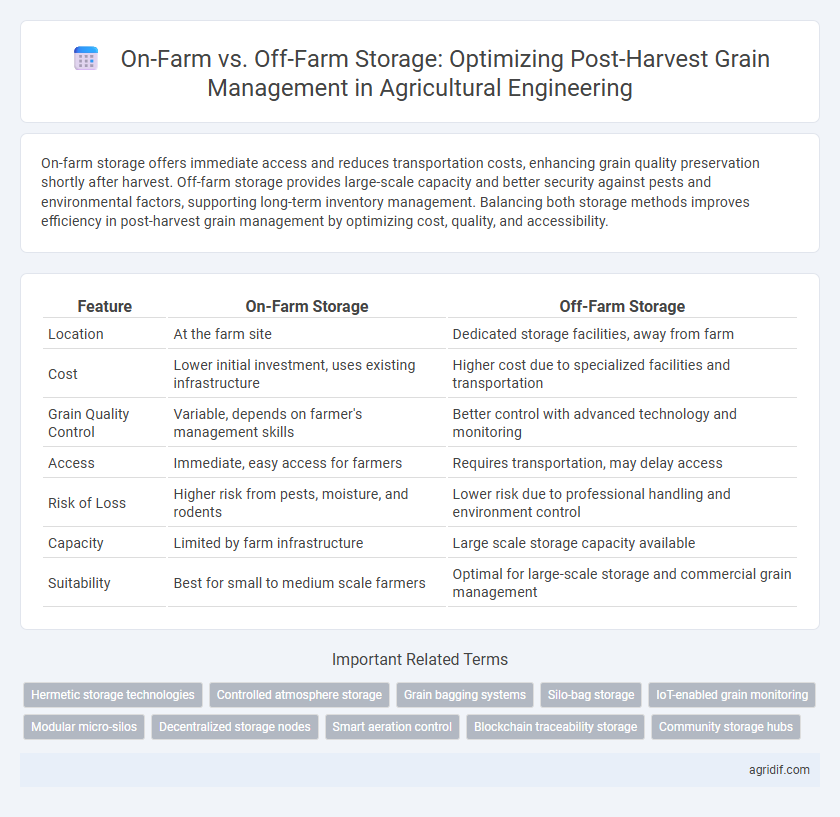

On-farm storage offers immediate access and reduces transportation costs, enhancing grain quality preservation shortly after harvest. Off-farm storage provides large-scale capacity and better security against pests and environmental factors, supporting long-term inventory management. Balancing both storage methods improves efficiency in post-harvest grain management by optimizing cost, quality, and accessibility.

Table of Comparison

| Feature | On-Farm Storage | Off-Farm Storage |

|---|---|---|

| Location | At the farm site | Dedicated storage facilities, away from farm |

| Cost | Lower initial investment, uses existing infrastructure | Higher cost due to specialized facilities and transportation |

| Grain Quality Control | Variable, depends on farmer's management skills | Better control with advanced technology and monitoring |

| Access | Immediate, easy access for farmers | Requires transportation, may delay access |

| Risk of Loss | Higher risk from pests, moisture, and rodents | Lower risk due to professional handling and environment control |

| Capacity | Limited by farm infrastructure | Large scale storage capacity available |

| Suitability | Best for small to medium scale farmers | Optimal for large-scale storage and commercial grain management |

Introduction to On-Farm and Off-Farm Grain Storage

On-farm grain storage enables farmers to maintain control over moisture levels and pest management immediately after harvest, reducing post-harvest losses and improving grain quality. Off-farm storage facilities typically offer large-scale capacity with advanced preservation technologies but may involve higher transportation costs and delayed market access. Strategic decisions between on-farm and off-farm storage impact overall grain supply chain efficiency, cost-effectiveness, and food security outcomes.

Key Differences Between On-Farm and Off-Farm Storage Systems

On-farm storage systems provide immediate accessibility and control over grains, enabling farmers to manage moisture levels and reduce post-harvest losses through timely interventions. Off-farm storage facilities typically offer larger capacity and advanced preservation technologies, such as controlled atmospheres and aeration systems, designed for long-term grain stability and quality maintenance. Cost implications, security measures, and logistical considerations also differ significantly between the two, influencing decisions based on farm size, crop type, and market access.

Cost Analysis: On-Farm vs Off-Farm Grain Storage

On-farm grain storage typically reduces transportation expenses and allows immediate access for farm use or sale, lowering overall handling costs. Off-farm storage often involves higher fees due to facility rental, third-party management, and additional logistics, which can increase post-harvest losses due to delayed marketing. Cost analysis reveals that on-farm storage investment in durable silos or bins can yield long-term savings and improved grain quality control compared to recurrent off-farm storage charges.

Grain Quality Preservation in Different Storage Options

On-farm storage systems, such as silos and storage bins, allow immediate control over grain moisture and aeration, reducing the risk of spoilage and pest infestation. Off-farm storage facilities often provide advanced climate control and professional pest management, enhancing long-term grain quality preservation. Selection between on-farm and off-farm storage depends on factors like storage duration, volume, and available technology to maintain optimal grain condition.

Infrastructure and Equipment Requirements

On-farm storage for post-harvest grain management requires investment in easily accessible silos, moisture control systems, and pest management equipment tailored to farm scale. Off-farm storage facilities demand more advanced infrastructure, including large-capacity grain elevators, aeration systems, and climate control technologies to ensure prolonged preservation and centralized handling. Choosing between on-farm and off-farm options involves evaluating equipment costs, maintenance requirements, and the need for scalable storage solutions aligned with grain production volumes.

Accessibility and Convenience for Farmers

On-farm storage offers farmers immediate accessibility to grain, enabling quicker response to market demands and timely quality checks, which enhances operational convenience. Off-farm storage, while often providing advanced preservation technology and larger capacity, may pose logistical challenges due to required transportation, potentially increasing time and costs. Farmers must weigh the trade-offs between on-site ease of access and the enhanced facilities of off-site storage to optimize post-harvest grain management.

Risk Management: Pests, Weather, and Security

On-farm storage systems enable farmers to closely monitor grain quality and quickly respond to pest infestations and weather-related risks, reducing spoilage and loss. Off-farm storage facilities typically offer advanced pest control measures, climate regulation, and enhanced security against theft, ensuring long-term preservation of grain stocks. Effective risk management balances timely access to grain with protection from environmental hazards and security threats.

Impact on Supply Chain and Market Timing

On-farm storage enables farmers to control the timing of grain sales, reducing dependence on immediate market conditions and enhancing supply chain flexibility by allowing delayed market entry during peak demand. Off-farm storage facilities, often larger and more centralized, improve aggregation and standardization, facilitating better logistics management and smoother supply chain coordination. Effective use of both storage types optimizes market timing, minimizes post-harvest losses, and stabilizes grain prices by balancing supply fluctuations.

Environmental Considerations of Storage Choices

On-farm storage minimizes transportation-related carbon emissions by reducing the need to move grain to distant facilities, thereby lowering overall environmental impact. Off-farm storage often involves large centralized facilities with advanced climate control technologies that can reduce post-harvest losses but may consume more energy. Sustainable post-harvest grain management requires balancing on-farm storage's lower emission benefits against off-farm options' efficiencies in moisture and pest control to optimize environmental outcomes.

Decision Factors for Choosing the Optimal Storage Solution

Key decision factors for choosing between on-farm and off-farm storage in post-harvest grain management include storage capacity, cost-effectiveness, grain quality preservation, and accessibility. On-farm storage offers immediate control and reduces transportation losses, while off-farm storage provides economies of scale and professional management but may increase handling risks. Evaluating climatic conditions, infrastructure availability, and market timing is essential to optimize grain storage solutions and ensure crop value retention.

Related Important Terms

Hermetic storage technologies

Hermetic storage technologies in on-farm storage prevent grain spoilage by creating airtight environments that inhibit oxygen and moisture exchange, preserving grain quality and reducing pest infestation. Off-farm storage facilities using hermetic systems ensure large-scale grain protection with controlled conditions, enhancing long-term preservation and minimizing post-harvest losses.

Controlled atmosphere storage

Controlled atmosphere storage enhances on-farm grain preservation by regulating oxygen, carbon dioxide, and humidity levels, significantly reducing pest infestation and spoilage compared to traditional off-farm storage methods. This technology ensures higher grain quality and extends shelf life, optimizing post-harvest management and reducing losses during storage periods.

Grain bagging systems

Grain bagging systems in on-farm storage offer flexible, cost-effective solutions that reduce the risks of contamination and pest infestation by minimizing handling and exposure, while off-farm storage typically involves large-scale facilities but incurs higher transportation and operational costs. Effective post-harvest grain management prioritizes on-farm grain bagging to maintain grain quality and moisture control, enhancing storage longevity and market value.

Silo-bag storage

Silo-bag storage offers a flexible and cost-effective on-farm solution for post-harvest grain management, reducing transportation risks and maintaining grain quality through controlled aeration and moisture levels. Compared to off-farm storage, silo-bags enable farmers to store grains close to the harvest site, minimizing losses and facilitating timely market access.

IoT-enabled grain monitoring

IoT-enabled grain monitoring in on-farm storage systems enhances real-time tracking of temperature, humidity, and pest activity, reducing spoilage and improving grain quality directly at the source. Off-farm storage facilities equipped with advanced IoT sensors provide centralized data analytics and remote management capabilities, offering scalable solutions for large-scale post-harvest grain preservation and supply chain optimization.

Modular micro-silos

Modular micro-silos offer on-farm storage solutions that enhance grain preservation by reducing transportation costs and minimizing post-harvest losses through controlled temperature and moisture conditions. Unlike off-farm storage facilities, these scalable units provide farmers with flexible capacity management and immediate access to stored grains, improving supply chain efficiency and market responsiveness.

Decentralized storage nodes

Decentralized on-farm storage nodes enhance post-harvest grain management by reducing transportation costs, minimizing grain spoilage through timely drying and aeration, and increasing farmers' control over inventory. Off-farm storage facilities often face challenges like overcrowding and delayed grain turnarounds, whereas on-farm decentralized storage supports localized supply chains and improves overall grain quality preservation.

Smart aeration control

Smart aeration control in on-farm storage optimizes grain temperature and moisture levels, reducing spoilage and maintaining quality directly at the harvest site. Off-farm storage benefits from advanced automation and remote monitoring systems, enabling precise airflow management to extend grain shelf life and minimize post-harvest losses during transportation and commercialization.

Blockchain traceability storage

On-farm storage allows immediate grain preservation with direct control and integration of blockchain traceability systems, ensuring transparent and tamper-proof post-harvest data management from harvest to consumption. Off-farm storage facilities, equipped with blockchain-enabled logistics and quality tracking, provide scalable, secure solutions for bulk grain storage while maintaining traceability for supply chain verification and market access.

Community storage hubs

Community storage hubs enhance post-harvest grain management by providing centralized on-farm storage solutions that reduce losses from pests and moisture while improving access to collective resources and market opportunities. These hubs foster collaborative grain preservation, optimize storage capacity utilization, and facilitate timely distribution compared to traditional off-farm storage systems.

On-farm storage vs off-farm storage for post-harvest grain management Infographic

agridif.com

agridif.com