Earthen ponds provide a natural habitat with cost-effective construction and better water retention for catfish farming, promoting organic nutrient cycling essential for fish growth. Lined ponds offer enhanced control over water quality, reduced seepage, and easier maintenance, leading to higher productivity and disease management. Choosing between earthen and lined ponds depends on factors like budget, soil permeability, and desired production scale in catfish aquaculture.

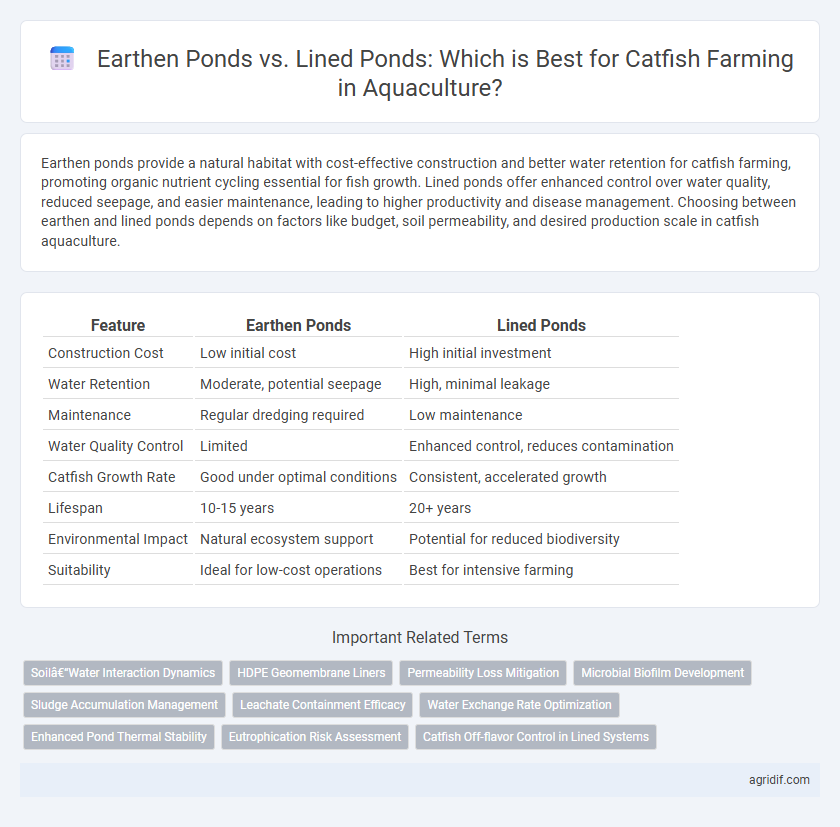

Table of Comparison

| Feature | Earthen Ponds | Lined Ponds |

|---|---|---|

| Construction Cost | Low initial cost | High initial investment |

| Water Retention | Moderate, potential seepage | High, minimal leakage |

| Maintenance | Regular dredging required | Low maintenance |

| Water Quality Control | Limited | Enhanced control, reduces contamination |

| Catfish Growth Rate | Good under optimal conditions | Consistent, accelerated growth |

| Lifespan | 10-15 years | 20+ years |

| Environmental Impact | Natural ecosystem support | Potential for reduced biodiversity |

| Suitability | Ideal for low-cost operations | Best for intensive farming |

Introduction to Catfish Farming: Earthen vs Lined Ponds

Earthen ponds, commonly used in catfish farming, offer natural water retention and promote beneficial microbial activity, supporting fish health and growth. Lined ponds, constructed with impermeable materials like HDPE, minimize water loss, reduce contamination risks, and enable precise control over water quality parameters. Choosing between earthen and lined ponds depends on factors such as soil permeability, water availability, budget constraints, and desired production intensity in catfish aquaculture.

Construction and Initial Investment: Earthen Ponds vs Lined Ponds

Earthen ponds for catfish farming require lower initial investment due to the use of natural soil, reducing construction costs but needing careful site selection and soil testing. Lined ponds involve higher upfront expenses because of synthetic liner materials like HDPE or PVC, which provide impermeability and durability, minimizing water loss and improving biosecurity. Construction time for lined ponds is typically longer, with added labor for installation and material handling compared to earthen pond excavation and shaping.

Water Quality Management in Earthen and Lined Ponds

Water quality management in catfish farming varies significantly between earthen and lined ponds due to differences in permeability and nutrient retention; earthen ponds often require more frequent monitoring of dissolved oxygen levels, ammonia, and pH to mitigate sediment interactions and prevent water quality degradation. Lined ponds, typically constructed with impermeable materials like HDPE, provide greater control over water parameters by minimizing seepage and sediment contamination, facilitating more stable environments for catfish growth. Proper aeration and regular water exchange protocols remain critical in both pond types to sustain optimal water quality and ensure high survival rates.

Soil Interaction and Nutrient Dynamics

Earthen ponds for catfish farming allow natural soil-water interactions that enhance nutrient recycling through microbial activity, promoting organic matter breakdown and nutrient availability. Lined ponds, often using impermeable materials like HDPE, minimize soil contact, reducing nutrient exchange and potential contamination but requiring external nutrient supplementation to maintain water quality and fish health. Soil composition in earthen ponds directly influences nutrient dynamics, affecting ammonia and phosphorus levels critical to catfish growth rates and pond productivity.

Fish Growth Performance in Different Pond Types

Earthen ponds provide a natural environment that supports beneficial microbial activity, enhancing nutrient availability and promoting catfish growth rates between 15-20% higher than lined ponds under similar conditions. Lined ponds, typically constructed with impermeable materials like HDPE or concrete, offer improved water quality control and reduced seepage but may result in slightly slower growth performance due to limited natural nutrient cycles and reduced microbial diversity. Optimizing pond type selection for catfish farming involves balancing growth rate advantages in earthen ponds with the operational advantages of lined ponds, depending on site-specific water availability and management goals.

Disease Control and Biosecurity Considerations

Earthen ponds for catfish farming offer natural microbial balance but pose higher risks for disease transmission due to limited biosecurity and water infiltration from surrounding soil and wildlife. Lined ponds provide a controlled environment with impermeable barriers, significantly reducing pathogen entry and enabling effective sanitation and quarantine measures. Optimal disease control in lined ponds relies on rigorous biosecurity protocols, including regular disinfection and restricted water exchange to prevent contamination.

Maintenance Requirements and Long-Term Durability

Earthen ponds require regular maintenance involving sediment management and bank repairs to prevent erosion and maintain water quality in catfish farming. Lined ponds, constructed with high-density polyethylene (HDPE) or clay liners, offer enhanced durability by minimizing seepage and reducing workload associated with frequent dredging and patching. Farms using lined ponds benefit from lower long-term operational costs and improved structural integrity, ensuring stable production over extended periods.

Environmental Impact: Sustainability and Land Use

Earthen ponds in catfish farming offer natural water filtration and promote local biodiversity, enhancing ecosystem sustainability but may require significant land alteration, affecting soil and nearby water bodies. Lined ponds prevent seepage and reduce groundwater contamination, resulting in more efficient water usage and minimal land disruption, yet involve synthetic materials that pose disposal and long-term environmental challenges. Balancing sustainability and land use efficiency depends on site conditions and farm management practices, with earthen ponds favoring ecological integration and lined ponds prioritizing resource containment.

Cost-Benefit Analysis: Profitability in Catfish Farming

Earthen ponds have lower initial construction costs but may incur higher maintenance expenses due to seepage and water quality management, affecting overall profitability in catfish farming. Lined ponds require significant upfront investment for materials like HDPE or PVC liners but offer improved water retention, reduced labor for pond maintenance, and higher survival rates of catfish, potentially increasing long-term profit margins. Cost-benefit analysis shows lined ponds deliver greater economic returns in intensive farming systems despite higher initial costs, while earthen ponds remain viable for low-input, extensive operations due to minimal capital requirements.

Choosing the Right Pond System for Your Catfish Farm

Selecting the optimal pond system for catfish farming depends on factors like soil permeability, cost, and water retention. Earthen ponds offer natural habitat benefits and lower initial costs but may require frequent maintenance due to seepage and erosion. Lined ponds, typically using HDPE or PVC liners, provide superior water control and biosecurity, making them ideal for intensive catfish production and minimizing disease risks.

Related Important Terms

Soil–Water Interaction Dynamics

Earthen ponds for catfish farming enable natural soil-water interactions that enhance nutrient recycling and support microbial activity, promoting healthy fish growth. Lined ponds minimize seepage and contaminant exchange but limit beneficial soil nutrient contributions, requiring precise water quality management to maintain optimal catfish production.

HDPE Geomembrane Liners

HDPE geomembrane liners in catfish aquaculture provide superior durability, impermeability, and resistance to UV radiation compared to traditional earthen ponds, significantly reducing water seepage and contamination risks. These liners enhance water quality management and fish health by creating a controlled environment, ultimately improving yield and operational efficiency in commercial catfish farming.

Permeability Loss Mitigation

Earthen ponds for catfish farming inherently face higher permeability loss due to soil porosity, necessitating frequent water replenishment and increased maintenance costs. Lined ponds utilize impermeable materials such as HDPE liners or clay composites to significantly reduce water seepage, enhancing water retention efficiency and promoting stable growth conditions.

Microbial Biofilm Development

Earthen ponds promote more diverse microbial biofilm development due to their natural soil substrates, which enhance nutrient cycling and improve water quality for catfish farming. Lined ponds, although easier to clean and maintain, often exhibit reduced microbial biofilm complexity, potentially limiting beneficial microbial interactions essential for healthy catfish growth.

Sludge Accumulation Management

Earthen ponds in catfish farming typically experience higher rates of sludge accumulation due to natural soil deposition and organic waste buildup, necessitating regular draining and mechanical dredging to maintain water quality and fish health. Lined ponds, with impermeable barriers such as polyethylene liners, significantly reduce sludge buildup by preventing soil infiltration, enabling easier sludge management and more consistent water quality control critical for optimal catfish growth.

Leachate Containment Efficacy

Lined ponds for catfish farming demonstrate superior leachate containment efficacy by preventing nutrient-rich water seepage into surrounding soil and groundwater, thereby reducing environmental pollution risks compared to earthen ponds. Earthen ponds often experience higher leachate infiltration due to soil permeability, leading to potential contamination and decreased water quality essential for sustainable aquaculture operations.

Water Exchange Rate Optimization

Earthen ponds provide natural filtration and microbial activity that help maintain water quality but often require lower water exchange rates to prevent erosion and turbidity, whereas lined ponds allow for higher and more controlled water exchange rates, improving oxygen levels and waste removal efficiency. Optimizing water exchange in lined ponds enhances catfish growth and reduces disease risk by maintaining stable physicochemical conditions, making them more suitable for intensive catfish farming operations.

Enhanced Pond Thermal Stability

Earthen ponds offer superior thermal stability for catfish farming due to their natural insulation properties, which help maintain consistent water temperatures critical for fish growth and health. In contrast, lined ponds often experience rapid temperature fluctuations that can stress catfish, potentially reducing growth rates and increasing susceptibility to disease.

Eutrophication Risk Assessment

Earthen ponds for catfish farming are more prone to eutrophication due to nutrient runoff and organic matter accumulation, which can lead to harmful algal blooms and oxygen depletion. Lined ponds offer better control over water quality and nutrient management, significantly reducing the risk of eutrophication and improving sustainable aquaculture practices.

Catfish Off-flavor Control in Lined Systems

Lined ponds offer superior control of catfish off-flavor by minimizing organic matter accumulation and reducing blue-green algae growth, key contributors to undesirable taste in catfish flesh. Compared to earthen ponds, lined systems enhance water quality management, leading to improved flavor profiles and higher market value in catfish farming.

Earthen Ponds vs Lined Ponds for Catfish Farming Infographic

agridif.com

agridif.com