HTST (High-Temperature Short-Time) processing applies moderate heat for a brief period, preserving more nutrients and maintaining a fresher taste in liquid foods compared to UHT (Ultra-High Temperature) treatment. UHT processing uses higher temperatures for a few seconds, enabling longer shelf life without refrigeration but can cause subtle changes in flavor and nutrient degradation. Choosing between HTST and UHT depends on the desired balance between shelf stability, nutritional retention, and taste quality in liquid food products.

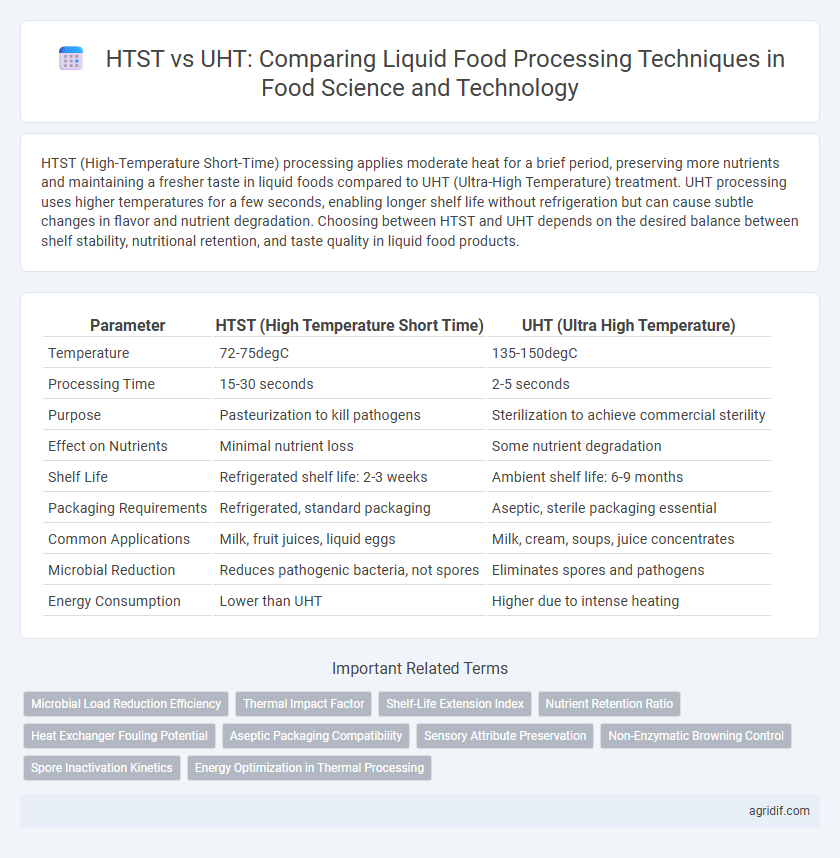

Table of Comparison

| Parameter | HTST (High Temperature Short Time) | UHT (Ultra High Temperature) |

|---|---|---|

| Temperature | 72-75degC | 135-150degC |

| Processing Time | 15-30 seconds | 2-5 seconds |

| Purpose | Pasteurization to kill pathogens | Sterilization to achieve commercial sterility |

| Effect on Nutrients | Minimal nutrient loss | Some nutrient degradation |

| Shelf Life | Refrigerated shelf life: 2-3 weeks | Ambient shelf life: 6-9 months |

| Packaging Requirements | Refrigerated, standard packaging | Aseptic, sterile packaging essential |

| Common Applications | Milk, fruit juices, liquid eggs | Milk, cream, soups, juice concentrates |

| Microbial Reduction | Reduces pathogenic bacteria, not spores | Eliminates spores and pathogens |

| Energy Consumption | Lower than UHT | Higher due to intense heating |

Introduction to Liquid Food Processing Technologies

High-Temperature Short-Time (HTST) and Ultra-High Temperature (UHT) processing are critical thermal techniques used in liquid food processing to ensure safety and extend shelf life. HTST involves heating liquid foods to 72degC for at least 15 seconds, effectively reducing microbial load while maintaining sensory quality. UHT processing heats products above 135degC for a few seconds, enabling aseptic packaging and long-term room temperature storage without preservatives.

Overview of HTST (High-Temperature Short-Time) Processing

HTST (High-Temperature Short-Time) processing heats liquid foods to temperatures typically between 72degC and 75degC for 15 to 30 seconds, effectively reducing pathogenic microorganisms while preserving sensory and nutritional qualities. This method is commonly applied in pasteurization of milk and fruit juices to ensure safety without significant alteration of flavor or texture. HTST balances microbial safety with retention of vitamins and enzymes better than higher temperature processes like UHT, making it suitable for products requiring refrigeration and shorter shelf life.

Understanding UHT (Ultra-High Temperature) Processing

UHT (Ultra-High Temperature) processing involves heating liquid foods to temperatures of 135-150degC for 2-5 seconds, effectively sterilizing the product by destroying all microorganisms and spores. This method extends shelf life significantly, allowing liquid foods to remain stable at room temperature for several months without refrigeration. UHT preserves nutritional quality and taste better than traditional High Temperature Short Time (HTST) pasteurization, making it ideal for milk, juice, and other beverages requiring long-term storage.

Key Differences Between HTST and UHT Methods

HTST (High-Temperature Short-Time) processing involves heating liquid foods to 72-75degC for 15-30 seconds, preserving more natural flavor and nutrients while achieving pasteurization. UHT (Ultra-High Temperature) processing heats liquids to 135-150degC for 2-5 seconds, extending shelf life up to six months without refrigeration but may cause slight changes in taste and nutrient profile. Key differences include processing temperature, time, shelf life, flavor retention, and packaging requirements, impacting the selection based on product type and distribution needs.

Impact on Nutritional Quality: HTST vs UHT

HTST (High-Temperature Short-Time) processing preserves more heat-sensitive nutrients like vitamin C and certain B vitamins in liquid foods compared to UHT (Ultra-High Temperature) processing, which subject liquids to higher temperatures for longer durations. UHT treatment extends shelf life significantly by sterilizing products but can cause greater degradation of proteins and loss of bioactive compounds. Nutritional quality in HTST-processed liquids remains closer to fresh products, making it preferable for preserving nutritional value in beverages like milk and fruit juices.

Microbial Safety and Shelf Life Comparison

HTST (High-Temperature Short-Time) processing exposes liquid foods to temperatures of 72degC for 15 seconds, effectively reducing pathogenic microorganisms while preserving nutrients and flavor, resulting in a refrigerated shelf life of 10-21 days. UHT (Ultra-High Temperature) processing heats products to 135-150degC for 2-5 seconds, achieving commercial sterility by inactivating spores and heat-resistant bacteria, which extends shelf life to 6-9 months at ambient temperature without refrigeration. Microbial safety in UHT-treated liquids is higher due to complete sterilization, whereas HTST ensures microbial reduction but requires cold storage to prevent spoilage.

Effects on Sensory Properties of Liquid Foods

High Temperature Short Time (HTST) processing preserves the natural flavor and aroma of liquid foods better than Ultra High Temperature (UHT) treatment, which can cause a cooked or caramelized taste due to higher heat exposure. HTST maintains a fresher sensory profile by minimizing nutrient degradation and preserving volatile compounds responsible for taste and smell. UHT extends shelf life significantly but often alters texture and color, leading to less desirable sensory qualities compared to HTST-treated liquids.

Energy Consumption and Environmental Considerations

HTST (High-Temperature Short Time) processing for liquid foods consumes less energy compared to UHT (Ultra-High Temperature) due to shorter heating periods and lower peak temperatures, reducing overall energy demand. UHT processing, while energy-intensive, extends shelf life significantly, lowering transportation and storage emissions by minimizing refrigeration needs. From an environmental perspective, HTST favors reduced immediate energy consumption, whereas UHT supports sustainability through decreased food waste and prolonged product stability.

Industrial Applications of HTST and UHT in the Food Sector

HTST (High-Temperature Short-Time) processing is widely used in the dairy industry for pasteurizing milk, preserving nutritional quality while extending shelf life through rapid heating at 72degC for 15 seconds. UHT (Ultra-High Temperature) processing applies sterilization at temperatures above 135degC for 2-5 seconds, enabling aseptic packaging and room-temperature storage of liquid foods like milk and fruit juices for several months. Industrial applications leverage HTST for products requiring refrigeration and UHT for those demanding long shelf stability without preservatives, optimizing processing efficiency and reducing microbial risks.

Future Trends and Innovations in Thermal Food Processing

Future trends in thermal food processing emphasize combining HTST (High-Temperature Short Time) and UHT (Ultra-High Temperature) technologies with emerging techniques like microwave-assisted heating and pulse electric fields to enhance energy efficiency and nutrient retention. Innovations include the development of advanced sensors and AI-driven process control systems for real-time monitoring and precise thermal treatment, reducing microbial load while preserving sensory qualities. Integration of sustainable practices such as waste heat recovery and eco-friendly packaging materials is poised to redefine thermal processing standards for liquid foods.

Related Important Terms

Microbial Load Reduction Efficiency

High-Temperature Short-Time (HTST) processing achieves microbial load reduction by rapidly heating liquid foods to 72degC for 15 seconds, effectively targeting vegetative pathogens while preserving sensory qualities. Ultra-High Temperature (UHT) processing heats liquids to 135-150degC for 2-5 seconds, enabling sterilization that eliminates both microbial spores and vegetative cells, resulting in extended shelf life without refrigeration.

Thermal Impact Factor

HTST (High Temperature Short Time) processing applies heat at 72-75degC for 15-30 seconds, preserving more nutrients and flavor compounds in liquid foods compared to UHT (Ultra-High Temperature) processing, which heats at 135-150degC for 2-5 seconds but may cause Maillard reactions and nutrient degradation. The thermal impact factor for HTST is lower, resulting in better retention of sensory attributes and bioactive components, while UHT offers longer shelf life through more intense thermal sterilization.

Shelf-Life Extension Index

High-Temperature Short-Time (HTST) processing extends the shelf life of liquid foods by 10 to 20 days under refrigerated conditions, leveraging rapid heat treatment to reduce microbial load while preserving sensory qualities. Ultra-High Temperature (UHT) processing achieves shelf life extension up to 6 months or more at ambient temperature by sterilizing liquid foods through brief exposure to temperatures above 135degC, enabling long-term storage without refrigeration.

Nutrient Retention Ratio

High-Temperature Short-Time (HTST) processing preserves higher nutrient retention ratios in liquid foods by applying moderate heat for a brief duration, effectively minimizing vitamin and enzyme degradation. Ultra-High Temperature (UHT) processing, while extending shelf life through sterilization at temperatures above 135degC, often results in greater loss of heat-sensitive nutrients like vitamin C and certain B vitamins due to intensified thermal exposure.

Heat Exchanger Fouling Potential

HTST (High-Temperature Short-Time) processing generally results in lower heat exchanger fouling potential compared to UHT (Ultra-High Temperature) due to shorter exposure times and moderate temperatures that reduce protein denaturation and mineral deposition on heat exchanger surfaces. UHT processing involves higher temperatures and longer heat exposure, which accelerate the aggregation of proteins and formation of mineral scales, thereby increasing fouling rates and requiring more frequent cleaning cycles in liquid food processing.

Aseptic Packaging Compatibility

HTST (High Temperature Short Time) processing maintains liquid food quality by applying moderate heat for a brief period, ensuring compatibility with conventional non-aseptic packaging but requiring refrigeration. UHT (Ultra High Temperature) processing sterilizes liquid food through rapid exposure to extremely high temperatures, enabling aseptic packaging that extends shelf life without refrigeration and preserves nutritional and sensory attributes.

Sensory Attribute Preservation

HTST (High-Temperature Short-Time) processing better preserves the sensory attributes of liquid foods by minimizing thermal exposure, which maintains flavor, color, and texture integrity compared to UHT (Ultra-High Temperature) treatment. UHT processing extends shelf life through higher temperatures but often causes cooked flavors and slight changes in sensory quality due to more intense heat exposure.

Non-Enzymatic Browning Control

High-Temperature Short-Time (HTST) processing effectively minimizes non-enzymatic browning in liquid foods by rapidly reducing microbial load at temperatures around 72degC for 15 seconds, preserving color and flavor. Ultra-High Temperature (UHT) processing, involving heating above 135degC for a few seconds, provides longer shelf life but can accelerate Maillard reactions, leading to increased browning and altered sensory qualities.

Spore Inactivation Kinetics

High-Temperature Short-Time (HTST) processing achieves partial spore inactivation through brief exposure at 72-75degC for 15-30 seconds, preserving nutritional quality but requiring refrigeration due to potential spore survival. Ultra-High Temperature (UHT) processing utilizes temperatures above 135degC for 2-5 seconds, ensuring complete inactivation of spores and extended shelf life at ambient conditions, albeit with greater heat-induced alterations in sensory and nutritional properties.

Energy Optimization in Thermal Processing

High-Temperature Short-Time (HTST) processing consumes less energy than Ultra-High Temperature (UHT) processing due to shorter heating durations and lower peak temperatures, optimizing thermal input for energy efficiency. HTST is ideal for liquid foods requiring mild thermal treatments to preserve nutrients while reducing energy costs, whereas UHT achieves longer shelf life but demands more intensive energy use.

HTST vs UHT for Liquid Food Processing Infographic

agridif.com

agridif.com