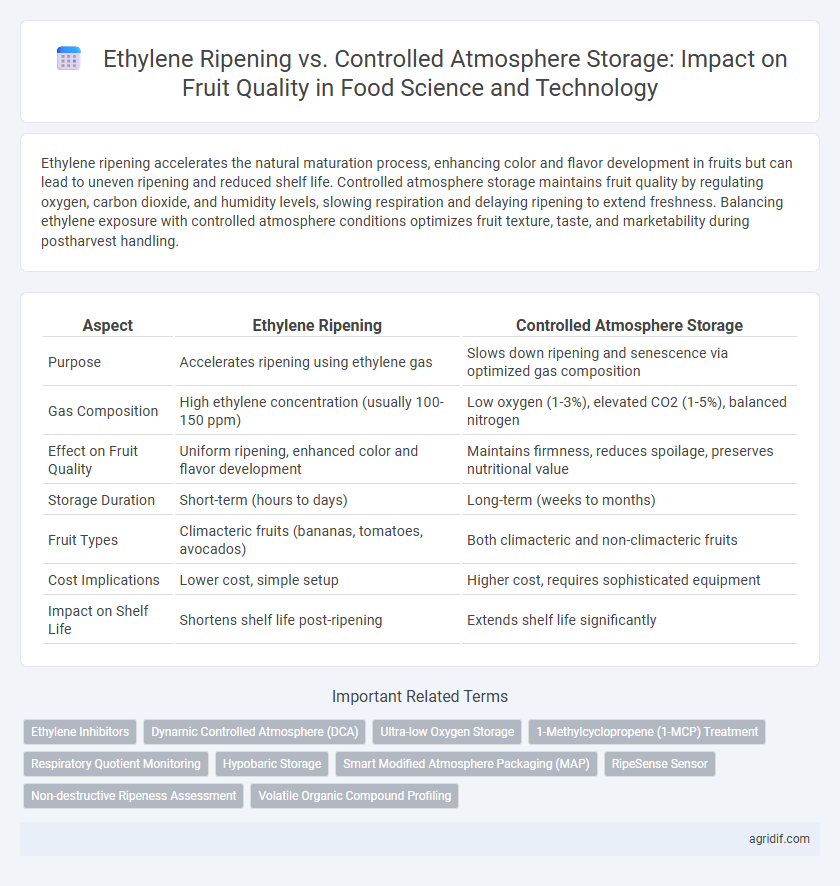

Ethylene ripening accelerates the natural maturation process, enhancing color and flavor development in fruits but can lead to uneven ripening and reduced shelf life. Controlled atmosphere storage maintains fruit quality by regulating oxygen, carbon dioxide, and humidity levels, slowing respiration and delaying ripening to extend freshness. Balancing ethylene exposure with controlled atmosphere conditions optimizes fruit texture, taste, and marketability during postharvest handling.

Table of Comparison

| Aspect | Ethylene Ripening | Controlled Atmosphere Storage |

|---|---|---|

| Purpose | Accelerates ripening using ethylene gas | Slows down ripening and senescence via optimized gas composition |

| Gas Composition | High ethylene concentration (usually 100-150 ppm) | Low oxygen (1-3%), elevated CO2 (1-5%), balanced nitrogen |

| Effect on Fruit Quality | Uniform ripening, enhanced color and flavor development | Maintains firmness, reduces spoilage, preserves nutritional value |

| Storage Duration | Short-term (hours to days) | Long-term (weeks to months) |

| Fruit Types | Climacteric fruits (bananas, tomatoes, avocados) | Both climacteric and non-climacteric fruits |

| Cost Implications | Lower cost, simple setup | Higher cost, requires sophisticated equipment |

| Impact on Shelf Life | Shortens shelf life post-ripening | Extends shelf life significantly |

Understanding Ethylene Ripening in Postharvest Fruit Management

Ethylene ripening accelerates enzymatic changes in postharvest fruit, enhancing color, texture, and flavor through targeted hormone application. Controlled atmosphere storage regulates oxygen, carbon dioxide, and humidity levels to slow respiration and delay ripening, maintaining firmness and extending shelf life. Understanding the balance between ethylene exposure and atmosphere control is essential for optimizing fruit quality and reducing postharvest losses.

Principles of Controlled Atmosphere Storage in Agriculture

Controlled atmosphere storage in agriculture involves regulating oxygen, carbon dioxide, and humidity levels to slow fruit metabolism and delay ripening, preserving texture and nutritional quality longer than ethylene ripening methods. By maintaining low oxygen concentrations (typically 1-3%) and elevated carbon dioxide levels (around 1-5%), respiration rates decrease, reducing ethylene production and limiting enzymatic degradation. This precise atmospheric manipulation extends shelf life, maintains firmness, and minimizes postharvest losses in fruits like apples, pears, and citrus compared to the accelerated ripening induced by exogenous ethylene exposure.

Comparative Effects on Fruit Shelf Life: Ethylene Ripening vs Controlled Atmosphere

Ethylene ripening accelerates fruit maturation by increasing respiration and ethylene production, which shortens shelf life through rapid softening and nutrient loss. Controlled atmosphere storage slows metabolic processes by reducing oxygen and increasing carbon dioxide levels, effectively extending shelf life and preserving firmness, color, and nutritional quality. Comparative studies demonstrate that controlled atmosphere storage maintains fruit quality for weeks longer than ethylene ripening, making it superior for long-term storage and transportation.

Impact on Nutritional Value: Ethylene Treatment and Atmosphere Control

Ethylene ripening accelerates fruit maturation by triggering enzymatic activities that enhance flavor but can degrade vitamin C and antioxidant levels faster than controlled atmosphere storage, which maintains low oxygen and elevated carbon dioxide to slow metabolism and preserve nutrients. Controlled atmosphere storage effectively retains key nutrients such as carotenoids, flavonoids, and phenolic compounds, extending shelf life without compromising nutritional integrity. Studies demonstrate that fruits stored under controlled atmospheres exhibit higher retention of ascorbic acid and reduced oxidative stress compared to those subjected to ethylene-induced ripening.

Flavor and Texture Changes under Different Ripening Methods

Ethylene ripening accelerates enzymatic activities, leading to rapid softening and intensified aroma compounds, which can enhance fruit flavor but may compromise texture uniformity. Controlled atmosphere storage slows metabolic processes by regulating oxygen and carbon dioxide levels, preserving firmness and maintaining balanced flavor profiles over extended periods. Flavor volatile retention and cell wall integrity under controlled atmospheres outperform ethylene ripening, ensuring superior texture consistency and longer shelf life in fruits like apples and bananas.

Influence on Fruit Color and Visual Quality

Ethylene ripening accelerates pigment biosynthesis, enhancing fruit color by increasing carotenoid and anthocyanin accumulation, but may lead to uneven coloration and over-ripening. Controlled atmosphere storage slows respiration and ethylene production, preserving chlorophyll and delaying color changes, thus maintaining consistent visual quality over extended periods. Optimizing gas composition and storage duration in controlled atmospheres effectively balances color retention with freshness, reducing postharvest losses.

Role in Reducing Postharvest Losses

Ethylene ripening accelerates fruit softening and color development, facilitating timely market readiness but may increase susceptibility to mechanical damage and spoilage. Controlled atmosphere storage reduces oxygen levels and increases carbon dioxide, slowing respiration and delaying ripening, effectively extending shelf life and minimizing postharvest losses. Combining ethylene treatment with controlled atmosphere conditions optimizes fruit quality by balancing accelerated ripening and preservation of texture and flavor.

Safety and Residue Considerations in Ripening Technologies

Ethylene ripening accelerates fruit maturation but raises concerns over residual gas exposure and workplace safety, necessitating stringent monitoring to prevent toxic accumulation. Controlled atmosphere storage maintains fruit quality by regulating oxygen, carbon dioxide, and humidity levels, minimizing microbial growth and chemical residues. Both technologies demand adherence to safety protocols and residue limits to ensure consumer health and compliance with food safety regulations.

Economic Aspects: Cost-Benefit Analysis for Producers

Ethylene ripening offers a lower initial investment and faster turnover for producers, making it cost-effective for short-term market demands. Controlled atmosphere storage requires higher capital costs and operational expenses but extends shelf life and reduces post-harvest losses, enhancing long-term profitability. Economic analyses show that controlled atmosphere storage maximizes returns in large-scale operations by preserving fruit quality and enabling flexible marketing strategies.

Future Trends in Fruit Quality Preservation Technologies

Ethylene ripening accelerates fruit maturation through ethylene gas exposure, enhancing flavor and texture but shortening shelf life, while controlled atmosphere (CA) storage extends freshness by regulating oxygen, carbon dioxide, and humidity levels to slow respiration and delay senescence. Emerging technologies combine CA storage with dynamic monitoring systems, such as real-time gas sensors and AI-driven atmosphere adjustments, to optimize fruit quality and reduce postharvest losses. Advances in nanotechnology and biopolymer coatings integrated with CA environments show promise for extending shelf life and maintaining nutritional content in diverse fruit varieties.

Related Important Terms

Ethylene Inhibitors

Ethylene inhibitors such as 1-Methylcyclopropene (1-MCP) extend fruit shelf life by blocking ethylene receptors, thereby delaying ripening and senescence more effectively than controlled atmosphere storage. These inhibitors preserve fruit firmness, color, and nutritional quality by mitigating ethylene-induced metabolic changes, offering a strategic advantage in postharvest handling over traditional storage methods.

Dynamic Controlled Atmosphere (DCA)

Dynamic Controlled Atmosphere (DCA) technology enhances fruit quality by continuously adjusting oxygen and carbon dioxide levels to slow respiration and delay ripening, outperforming traditional ethylene ripening methods that accelerate ripening through hormone application. DCA effectively maintains firmness, flavor, and nutritional value during storage, reducing spoilage and extending shelf life compared to static controlled atmosphere storage.

Ultra-low Oxygen Storage

Ultra-low oxygen storage maintains fruit firmness and delays senescence by reducing respiration rates more effectively than ethylene ripening, which accelerates ripening and softening through increased ethylene exposure. Controlled atmosphere storage optimizes oxygen and carbon dioxide levels, minimizing oxidative stress and preserving nutritional quality, whereas ethylene-based methods primarily target ripening acceleration without extending shelf life.

1-Methylcyclopropene (1-MCP) Treatment

1-Methylcyclopropene (1-MCP) treatment effectively inhibits ethylene receptors in fruit, delaying ripening and maintaining quality by reducing ethylene-induced softening, color changes, and spoilage. Compared to traditional ethylene ripening and controlled atmosphere storage, 1-MCP extends shelf life while preserving texture, flavor, and nutritional value, making it a critical technology in modern postharvest fruit management.

Respiratory Quotient Monitoring

Ethylene ripening accelerates fruit maturation by increasing respiration rates, often reflected in a higher Respiratory Quotient (RQ) indicating a shift towards carbohydrate metabolism. Controlled atmosphere storage maintains lower RQ values by reducing oxygen levels and increasing carbon dioxide, thereby slowing respiration and preserving fruit quality longer.

Hypobaric Storage

Hypobaric storage, a subset of controlled atmosphere techniques, significantly reduces ethylene production and respiration rates in fruits, thereby preserving texture, flavor, and nutritional content better than conventional ethylene ripening methods. This oxygen-limited environment delays senescence and microbial growth, extending shelf life while maintaining optimal fruit quality during postharvest storage.

Smart Modified Atmosphere Packaging (MAP)

Smart Modified Atmosphere Packaging (MAP) technology optimizes gas composition around fruit, significantly enhancing shelf life and maintaining nutritional quality compared to traditional ethylene ripening which accelerates softening and sensory degradation. By dynamically adjusting oxygen and carbon dioxide levels, Smart MAP slows respiration and delays ripening, preserving firmness, color, and flavor integrity in postharvest fruit storage.

RipeSense Sensor

Ethylene ripening accelerates fruit softening and color development but can lead to uneven ripening and reduced shelf life, whereas controlled atmosphere storage maintains fruit firmness and delays senescence by regulating oxygen and carbon dioxide levels. The RipeSense Sensor provides precise, non-destructive monitoring of fruit ripeness by detecting ethylene concentration, enabling optimized timing for ethylene treatment or controlled atmosphere adjustments to enhance fruit quality and reduce postharvest losses.

Non-destructive Ripeness Assessment

Ethylene ripening accelerates fruit maturation by increasing respiration rates and ethylene production, enabling rapid non-destructive ripeness assessment through technologies like near-infrared spectroscopy and electronic noses. Controlled atmosphere storage maintains optimal oxygen and carbon dioxide levels to slow metabolism, allowing consistent monitoring of fruit quality parameters such as firmness and chlorophyll fluorescence without damaging the fruit.

Volatile Organic Compound Profiling

Ethylene ripening accelerates fruit maturation by triggering specific Volatile Organic Compound (VOC) profiles associated with aroma and flavor development, whereas controlled atmosphere storage modulates VOC emissions through low oxygen and elevated CO2 levels to delay ripening and maintain quality. Comparative VOC profiling reveals that ethylene treatment enhances ester production linked to fruity notes, while controlled atmosphere storage suppresses aldehyde and alcohol derivatives, contributing to prolonged shelf life without compromising sensory attributes.

Ethylene ripening vs controlled atmosphere storage for fruit quality Infographic

agridif.com

agridif.com