Texture analyzers provide objective, precise measurements of food texture by quantifying parameters such as firmness, chewiness, and cohesiveness, offering consistent and reproducible data. Sensory panels, on the other hand, capture subjective human perceptions of texture, incorporating nuanced sensory experiences like mouthfeel and overall acceptability that instruments cannot fully replicate. Combining both methods enhances accuracy in food texture evaluation by integrating quantitative analysis with human sensory insight.

Table of Comparison

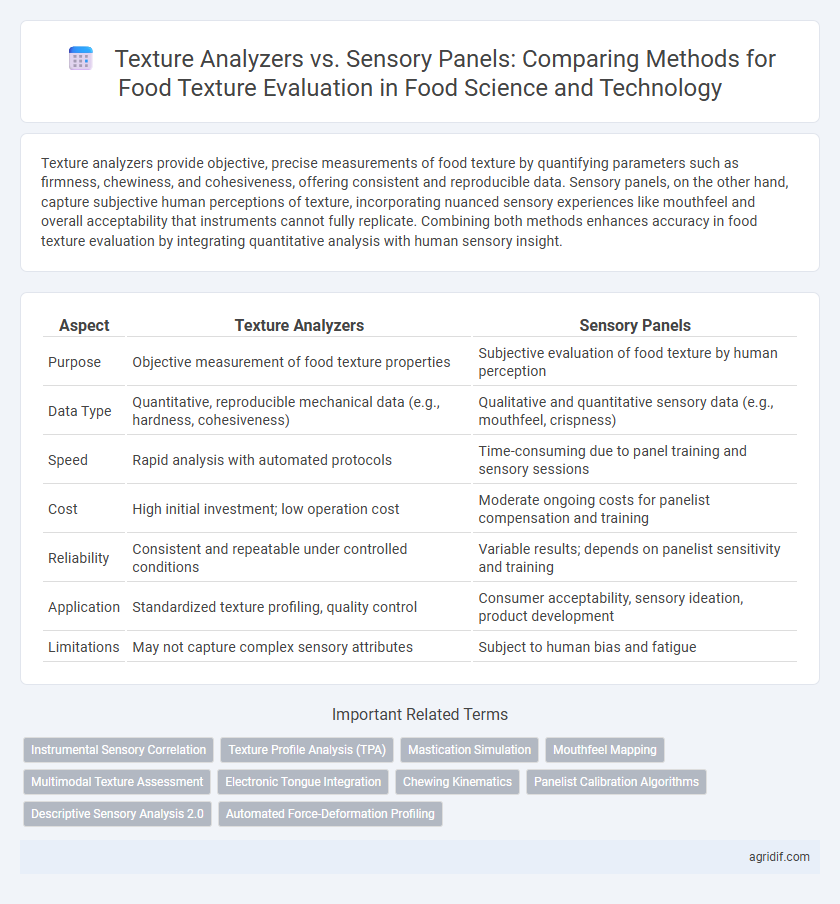

| Aspect | Texture Analyzers | Sensory Panels |

|---|---|---|

| Purpose | Objective measurement of food texture properties | Subjective evaluation of food texture by human perception |

| Data Type | Quantitative, reproducible mechanical data (e.g., hardness, cohesiveness) | Qualitative and quantitative sensory data (e.g., mouthfeel, crispness) |

| Speed | Rapid analysis with automated protocols | Time-consuming due to panel training and sensory sessions |

| Cost | High initial investment; low operation cost | Moderate ongoing costs for panelist compensation and training |

| Reliability | Consistent and repeatable under controlled conditions | Variable results; depends on panelist sensitivity and training |

| Application | Standardized texture profiling, quality control | Consumer acceptability, sensory ideation, product development |

| Limitations | May not capture complex sensory attributes | Subject to human bias and fatigue |

Introduction to Food Texture Evaluation Methods

Texture analyzers provide objective, quantitative measurements of food texture attributes such as hardness, cohesiveness, and adhesiveness through instrumental testing. Sensory panels rely on trained human assessors to evaluate texture based on perception, capturing nuances like mouthfeel and consistency that instruments may miss. Combining both methods enhances accuracy in food texture evaluation by integrating precise data with human sensory experience.

Understanding Texture Analyzers: Principles and Applications

Texture analyzers quantitatively measure food texture attributes such as hardness, cohesiveness, and springiness by applying controlled forces and recording deformation responses. These instruments utilize standardized test methods like compression, penetration, and tensile tests, ensuring objective and reproducible data for product development and quality control. Compared to sensory panels, texture analyzers offer precise instrumental insights into mechanical properties that correlate with consumer perception but do not fully capture complex mouthfeel and emotional responses.

The Role of Sensory Panels in Texture Assessment

Sensory panels provide critical insights into food texture by capturing human perceptions that texture analyzers cannot quantify, such as mouthfeel and emotional response. Trained panelists evaluate attributes like hardness, cohesiveness, and springiness, enabling nuanced understanding of consumer acceptance and preference. This human-centric approach complements instrumental data, ensuring comprehensive texture assessment in food product development.

Comparative Accuracy: Instrumental vs Sensory Texture Analysis

Texture analyzers provide precise, quantifiable measurements of food texture attributes such as firmness, cohesiveness, and elasticity using standardized mechanical tests, ensuring consistent and repeatable results. Sensory panels, while subjective, capture the complex human perception of texture, integrating factors like mouthfeel and tactile sensations that instruments may not fully replicate. Combining instrumental texture analysis with sensory evaluation offers a comprehensive understanding of food texture, balancing objective data with consumer experience for product development and quality control.

Key Advantages of Texture Analyzers in Food Science

Texture analyzers provide objective, reproducible measurements of food texture properties such as hardness, cohesiveness, and chewiness, which are critical for standardizing product quality in food science. These instruments allow for precise control over testing conditions, enabling detailed analysis of mechanical properties that sensory panels may not quantify consistently. Compared to sensory evaluation, texture analyzers reduce variability caused by human subjectivity and fatigue, ensuring reliable data for product development and quality control.

Limitations of Sensory Panels in Texture Evaluation

Sensory panels face inherent limitations in food texture evaluation due to subjective variability among panelists influenced by individual perception, fatigue, and environmental factors. The inability to provide quantifiable and reproducible data restricts the consistency and accuracy of sensory panel assessments. These challenges necessitate the complementary use of texture analyzers for objective, precise, and standardized measurements in food texture analysis.

Integration of Texture Analyzer Data with Sensory Panel Feedback

Texture analyzers provide precise, quantitative measurements of food texture attributes such as hardness, chewiness, and cohesiveness, enabling objective data collection. Sensory panels offer subjective, qualitative insights into how consumers perceive texture, capturing nuances beyond instrumental detection. Integrating texture analyzer data with sensory panel feedback enhances the accuracy of texture evaluation by correlating instrumental parameters with human sensory responses, improving product development and quality control in food science.

Cost and Efficiency Considerations for Texture Analysis Methods

Texture analyzers offer cost-effective and rapid quantitative measurements of food texture, reducing labor expenses and minimizing variability associated with human sensory panels. Sensory panels require greater investment in trained personnel and time for data collection and analysis, impacting overall efficiency and scalability. Automated texture analyzers enable high-throughput testing, providing consistent reproducibility critical for industrial applications in food texture evaluation.

Case Studies: Texture Analyzer and Sensory Panel Comparisons

Case studies comparing texture analyzers and sensory panels reveal distinct advantages in food texture evaluation, highlighting texture analyzers' precision in measuring objective parameters such as hardness, cohesiveness, and chewiness. Sensory panels provide valuable insights into consumer perception, capturing nuances like mouthfeel and aftertaste that instruments cannot quantify. Integrating data from texture analyzers with sensory panel feedback enhances the accuracy and relevance of texture assessments in product development and quality control.

Future Trends in Food Texture Evaluation Technologies

Emerging advancements in food texture evaluation prioritize integrating texture analyzers equipped with artificial intelligence and machine learning to enhance precision and predictive capabilities. Sensory panels increasingly incorporate virtual reality and biometric feedback systems to capture comprehensive consumer responses in real-time, bridging subjective perceptions with objective data. Future trends emphasize hybrid approaches combining instrumental analysis with digital sensory methodologies to revolutionize texture profiling and product development in Food Science and Technology.

Related Important Terms

Instrumental Sensory Correlation

Texture analyzers provide objective, quantifiable data on food texture parameters such as hardness, cohesiveness, and elasticity, which often correlate strongly with sensory panel evaluations. Establishing robust Instrumental Sensory Correlation enables food scientists to predict consumer perception more accurately, optimizing product formulation and quality control in food science and technology.

Texture Profile Analysis (TPA)

Texture analyzers provide objective, quantifiable data on food texture through Texture Profile Analysis (TPA), measuring parameters like hardness, cohesiveness, and springiness with high reproducibility. Sensory panels, while subjective, capture human perception and preferences, essential for correlating instrumental TPA data with consumer experience and refining product development.

Mastication Simulation

Texture analyzers provide objective, quantifiable data on food texture by simulating mastication forces and measuring mechanical properties such as hardness, cohesiveness, and chewiness with precision and reproducibility. Sensory panels capture subjective human perceptions of texture, including nuances of mastication experience like mouthfeel and particle breakdown, which are critical for understanding consumer acceptance but lack the consistency and quantifiable metrics offered by texture analyzers.

Mouthfeel Mapping

Texture analyzers provide precise, quantifiable data on food mechanical properties such as hardness, cohesiveness, and adhesiveness, enabling objective assessment of mouthfeel attributes. Sensory panels complement this by capturing nuanced human perception and emotional responses, essential for mouthfeel mapping in product development and quality control.

Multimodal Texture Assessment

Texture analyzers provide quantitative, reproducible measurements of food texture parameters such as hardness, cohesiveness, and chewiness through instrumental methods, enabling objective multimodal texture assessment. Sensory panels offer critical insights into consumer perception by evaluating complex texture attributes like mouthfeel and aftertaste, capturing nuances that instruments alone may not detect.

Electronic Tongue Integration

Texture analyzers provide objective, quantifiable measurements of food texture attributes such as hardness and cohesiveness, enabling standardized evaluation with high reproducibility. Integrating electronic tongue technology enhances sensory analysis by capturing complex flavor and texture interactions, complementing sensory panels with precise chemical and tactile data for comprehensive food texture profiling.

Chewing Kinematics

Texture analyzers provide objective, quantifiable data on food firmness, cohesiveness, and elasticity by simulating chewing forces, while sensory panels capture human perception of texture through chewing kinematics, including mastication rate and bite force variations. Integrating mechanical measurements from texture analyzers with dynamic sensory feedback enhances the accuracy of texture profiling critical for product development and quality control in Food Science and Technology.

Panelist Calibration Algorithms

Panelist calibration algorithms refine sensory panel data by minimizing individual biases and enhancing reproducibility in food texture evaluation, bridging subjective perceptions with objective measurements. Texture analyzers provide precise mechanical data, while calibrated panels capture nuanced sensory attributes, enabling comprehensive characterization through integrative analysis.

Descriptive Sensory Analysis 2.0

Texture analyzers provide objective, quantifiable measurements of food texture properties such as hardness, cohesiveness, and chewiness, enabling precise and reproducible data collection. Descriptive Sensory Analysis 2.0 integrates advanced data analytics and digital sensory technologies with traditional sensory panels, enhancing the depth and accuracy of human perception insights beyond instrument-based assessments.

Automated Force-Deformation Profiling

Texture analyzers provide precise, reproducible measurements through automated force-deformation profiling, capturing quantifiable data such as hardness, cohesiveness, and elasticity in food products. Sensory panels offer subjective, nuanced perception-based evaluations that incorporate human tactile and oral feedback, complementing instrumental data for comprehensive food texture analysis.

Texture analyzers vs Sensory panels for food texture evaluation Infographic

agridif.com

agridif.com