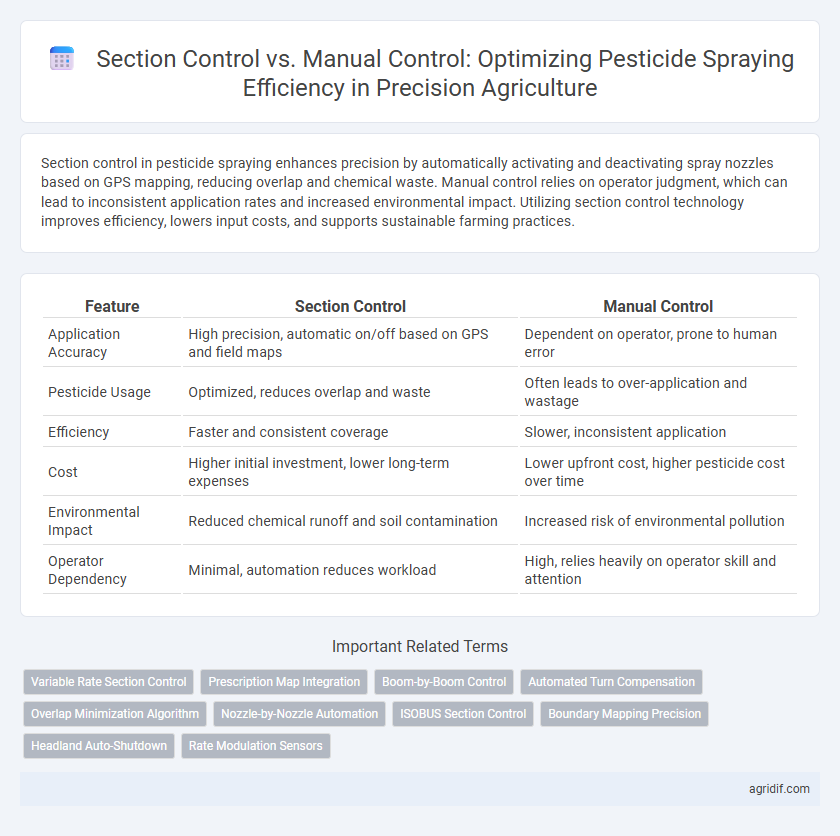

Section control in pesticide spraying enhances precision by automatically activating and deactivating spray nozzles based on GPS mapping, reducing overlap and chemical waste. Manual control relies on operator judgment, which can lead to inconsistent application rates and increased environmental impact. Utilizing section control technology improves efficiency, lowers input costs, and supports sustainable farming practices.

Table of Comparison

| Feature | Section Control | Manual Control |

|---|---|---|

| Application Accuracy | High precision, automatic on/off based on GPS and field maps | Dependent on operator, prone to human error |

| Pesticide Usage | Optimized, reduces overlap and waste | Often leads to over-application and wastage |

| Efficiency | Faster and consistent coverage | Slower, inconsistent application |

| Cost | Higher initial investment, lower long-term expenses | Lower upfront cost, higher pesticide cost over time |

| Environmental Impact | Reduced chemical runoff and soil contamination | Increased risk of environmental pollution |

| Operator Dependency | Minimal, automation reduces workload | High, relies heavily on operator skill and attention |

Introduction to Pesticide Spraying Methods

Section control in pesticide spraying utilizes GPS and sensor technology to automatically regulate spray application, minimizing overlap and reducing chemical usage. Manual control relies on operator judgment and timing, often leading to inconsistent coverage and increased risk of over-application. Precision agriculture increasingly favors section control methods to enhance efficiency, environmental safety, and crop health management.

What is Section Control?

Section control is an advanced technology in precision agriculture that automatically manages pesticide application by activating or deactivating spray nozzles based on GPS data and field maps. This system reduces chemical overlap and minimizes environmental impact by precisely targeting only treated areas, improving efficiency and cost-effectiveness. Manual control requires operator input for nozzle activation, often leading to uneven coverage and increased pesticide use.

Manual Control Overview in Pesticide Application

Manual control in pesticide spraying involves operators directly managing spray patterns and coverage without automated guidance systems, relying heavily on experience and visual assessment. This method can lead to inconsistent application rates and increased chemical usage, potentially affecting crop health and environmental sustainability. Despite advancements in technology, manual control remains prevalent in regions lacking access to precision agriculture tools or for small-scale farmers prioritizing low-cost solutions.

Key Differences Between Section Control and Manual Control

Section control in pesticide spraying uses GPS and sensor technology to automatically activate or deactivate spray nozzles in specific field zones, minimizing overlap and reducing chemical waste. Manual control relies on the operator's visual judgment to turn spray sections on or off, increasing the risk of over-application and inconsistent coverage. Section control enhances precision by targeting only designated areas, improving efficiency and environmental sustainability compared to manual control methods.

Efficiency and Accuracy: Comparing Results

Section control technology in pesticide spraying significantly improves efficiency by automatically activating and deactivating spray nozzles based on GPS field mapping, reducing overlap and missed areas. Manual control relies heavily on operator skill, often leading to inconsistent application rates and increased chemical waste. Studies show section control systems can increase spraying accuracy by up to 20%, optimizing pesticide use and minimizing environmental impact.

Impact on Pesticide Usage

Section control technology in pesticide spraying significantly reduces chemical usage by automatically activating or deactivating spray nozzles based on GPS-defined field boundaries and crop maps. Manual control often leads to overlapping spray passes and missed areas, increasing pesticide waste and environmental impact. Studies show section control can decrease pesticide consumption by up to 15-20%, enhancing cost efficiency and sustainability in precision agriculture.

Cost Implications and ROI

Section control in pesticide spraying significantly reduces chemical usage by targeting only specific areas, lowering overall operational costs compared to manual control. This precision minimizes waste and environmental impact, enhancing return on investment (ROI) through increased efficiency and reduced input expenses. Farms adopting section control report up to 20% cost savings and faster ROI periods, making it a financially advantageous technology over traditional manual spraying methods.

Environmental Sustainability Considerations

Section control in pesticide spraying significantly reduces chemical over-application by targeting only the required areas, minimizing environmental contamination and preserving soil health. Manual control often results in overlap and excessive pesticide use, increasing the risk of runoff and pollution of nearby water bodies. Precision agriculture technologies integrated with GPS and sensors enhance section control efficiency, promoting sustainable farming practices and reducing the ecological footprint.

Technology Integration and Farmer Adoption

Section control technology in pesticide spraying optimizes chemical application by using GPS and sensor data to activate or deactivate sprayer sections, reducing overlap and minimizing environmental impact compared to manual control methods. Farmers adopting section control report increased efficiency and cost savings due to precise spray targeting and reduced chemical use, enhancing sustainability in crop management. Integration of automated systems with digital farm management platforms facilitates seamless data analysis and decision-making, accelerating widespread adoption in precision agriculture.

Future Trends in Pesticide Application Control

Section control technology significantly reduces pesticide overlap and minimizes environmental impact by automatically activating and deactivating sprayer nozzles based on GPS-guided field boundaries, improving application accuracy compared to manual control. Future trends indicate integration with AI-driven analytics and real-time sensor data to further optimize pesticide usage, enhancing precision and sustainability. Advances in drone-based spraying and autonomous vehicles will also support adaptive section control, promoting efficient resource management and reduced chemical exposure.

Related Important Terms

Variable Rate Section Control

Variable Rate Section Control enhances pesticide application efficiency by automatically adjusting spray sections based on real-time field data, minimizing overlap and reducing chemical waste compared to Manual Control, which relies on operator judgment and uniform application rates. This technology not only optimizes input usage but also mitigates environmental impact by precisely targeting affected areas within diverse crop zones.

Prescription Map Integration

Section control in precision agriculture utilizes GPS-guided prescription map integration to automatically activate or deactivate pesticide spray sections, enhancing accuracy and reducing chemical waste. Manual control lacks this integration, making it less efficient by relying on operator judgment rather than data-driven, site-specific application patterns.

Boom-by-Boom Control

Boom-by-boom section control in pesticide spraying significantly reduces chemical overlap and environmental impact by precisely activating and deactivating individual boom sections based on GPS and crop mapping data. This targeted approach enhances application accuracy compared to manual control, leading to cost savings, minimized pesticide drift, and improved crop health.

Automated Turn Compensation

Section Control enhances pesticide spraying accuracy by automatically shutting off spray sections at field boundaries to prevent overlap and reduce chemical waste. Automated Turn Compensation adjusts spray rates during vehicle turns, maintaining consistent application and minimizing crop damage compared to manual control methods.

Overlap Minimization Algorithm

Section Control in pesticide spraying uses GPS-based Overlap Minimization Algorithms to precisely activate and deactivate spray nozzles, reducing chemical waste and environmental impact by eliminating redundant coverage. Compared to manual control, this technology enhances efficiency by maintaining accurate application rates and minimizing human error during field operations.

Nozzle-by-Nozzle Automation

Nozzle-by-nozzle automation in section control for pesticide spraying enhances precision by individually activating nozzles only where needed, reducing chemical waste and environmental impact. This technology outperforms manual control by enabling real-time adjustments based on crop variability and field conditions, improving both efficiency and sustainability in precision agriculture.

ISOBUS Section Control

ISOBUS Section Control technology enhances pesticide spraying by automatically activating and deactivating specific sections of the sprayer, reducing overlap and minimizing chemical waste, which manual control methods cannot achieve accurately. This precise application improves crop health and lowers input costs while supporting sustainable farming practices through efficient resource management.

Boundary Mapping Precision

Section control enhances pesticide spraying accuracy by using GPS-guided boundary mapping to activate and deactivate spray sections precisely within field zones, minimizing overlap and chemical waste. Manual control relies on operator judgment, which often leads to inconsistent coverage and increased risk of boundary overspray.

Headland Auto-Shutdown

Section Control technology in precision agriculture enables automatic pesticide spray shutdown at field headlands, reducing overlap and minimizing chemical waste compared to manual control methods. Headland Auto-Shutdown enhances operational efficiency by precisely stopping spray nozzles at field boundaries, lowering environmental impact and input costs.

Rate Modulation Sensors

Rate modulation sensors in section control systems optimize pesticide application by precisely adjusting spray rates based on real-time field variability, significantly reducing chemical waste and environmental impact compared to manual control methods. These sensors enhance efficiency by ensuring uniform coverage and preventing overlap, leading to cost savings and improved crop health in precision agriculture.

Section Control vs Manual Control for Pesticide Spraying Infographic

agridif.com

agridif.com