Section control technology in precision agriculture enhances pesticide application by targeting only specific areas that require treatment, reducing chemical use and minimizing environmental impact. Traditional spraying methods apply pesticides uniformly across entire fields, often leading to overspray and increased costs. Utilizing section control improves efficiency by conserving resources and promoting sustainable farming practices.

Table of Comparison

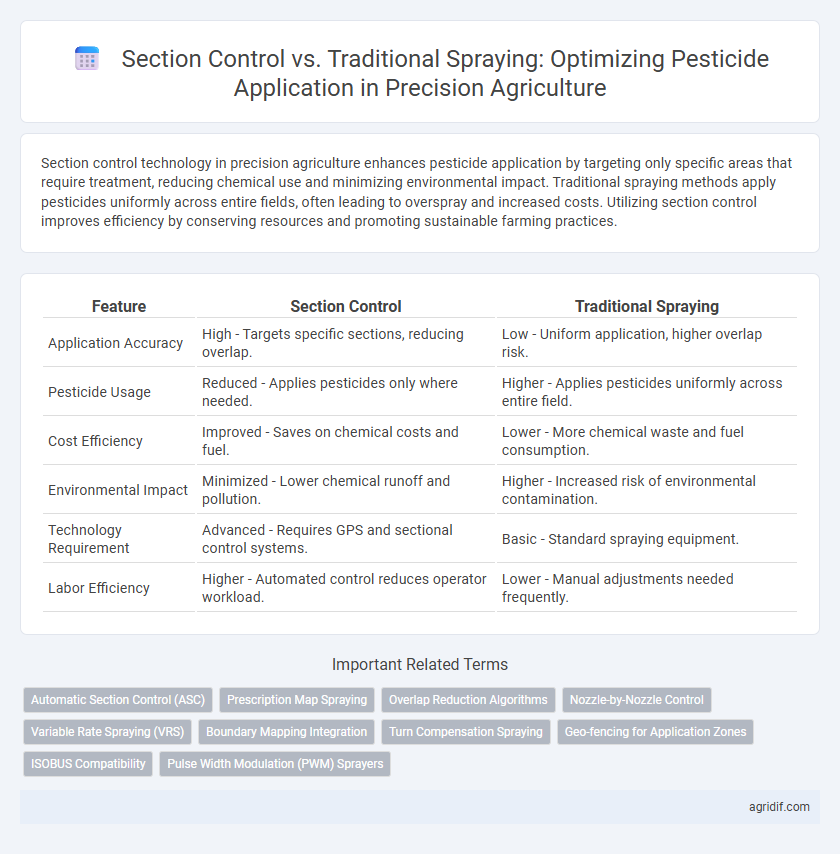

| Feature | Section Control | Traditional Spraying |

|---|---|---|

| Application Accuracy | High - Targets specific sections, reducing overlap. | Low - Uniform application, higher overlap risk. |

| Pesticide Usage | Reduced - Applies pesticides only where needed. | Higher - Applies pesticides uniformly across entire field. |

| Cost Efficiency | Improved - Saves on chemical costs and fuel. | Lower - More chemical waste and fuel consumption. |

| Environmental Impact | Minimized - Lower chemical runoff and pollution. | Higher - Increased risk of environmental contamination. |

| Technology Requirement | Advanced - Requires GPS and sectional control systems. | Basic - Standard spraying equipment. |

| Labor Efficiency | Higher - Automated control reduces operator workload. | Lower - Manual adjustments needed frequently. |

Introduction to Pesticide Application Methods

Section control technology in pesticide application significantly reduces chemical usage by targeting specific field zones, contrasting with traditional spraying methods that apply pesticides uniformly across entire fields. This precision approach minimizes environmental impact and lowers costs while maintaining crop protection efficacy. Traditional spraying often leads to over-application and increased pesticide drift, highlighting the advantages of adopting section control systems for sustainable agriculture.

Overview of Traditional Spraying Techniques

Traditional spraying techniques in pesticide application typically involve uniform coverage across entire fields, often leading to over-application on non-target areas and increased chemical waste. These methods rely on manual or mechanical boom sprayers that do not adjust for variations in crop density or pest presence, reducing efficiency and potentially causing environmental harm. Conventional spraying lacks real-time data integration, resulting in higher input costs and less precise pest management compared to advanced section control technologies.

What is Section Control in Precision Agriculture?

Section control in precision agriculture refers to the technology that automatically turns pesticide spraying sections on and off based on GPS positioning and field maps, reducing overlap and minimizing chemical usage. Unlike traditional spraying, which applies pesticides uniformly across entire fields regardless of crop variability, section control targets specific zones requiring treatment, enhancing efficiency and cost-effectiveness. This precision reduces environmental impact by limiting pesticide runoff and promoting sustainable farming practices.

Technology Behind Section Control Systems

Section control systems for pesticide application utilize GPS and real-time sensor technology to automatically activate and deactivate spray nozzles, preventing overlap and reducing chemical waste. These systems integrate with mapping software to create precise application zones based on field variability, enhancing efficiency compared to traditional spraying methods. Advanced algorithms process data from soil sensors and crop health monitors to optimize pesticide distribution, improving environmental sustainability and crop yield.

Accuracy Comparison: Section Control vs Traditional Spraying

Section control technology in pesticide application significantly enhances accuracy by targeting specific field zones, reducing overlap and minimizing pesticide waste compared to traditional spraying methods. Traditional spraying often results in over-application or under-application due to uniform coverage regardless of crop variability, leading to increased costs and environmental impact. Precision in section control is driven by GPS and sensor integration, enabling real-time adjustments that optimize pesticide usage and improve crop protection efficiency.

Impact on Chemical Usage and Cost Savings

Section control technology in precision agriculture significantly reduces chemical usage by targeting pesticide application only to affected zones, minimizing overlap and waste typical in traditional spraying methods. This targeted approach leads to substantial cost savings on pesticides and lowers environmental impact due to decreased chemical runoff. Studies show section control can reduce pesticide input by up to 25%, optimizing resources and enhancing overall farm profitability.

Environmental Benefits and Reduced Drift

Section control technology in pesticide application significantly reduces chemical drift by precisely targeting only treated areas, minimizing off-target exposure and contamination. Traditional spraying methods often result in substantial pesticide overuse and environmental pollution due to overlap and random application. By using GPS-guided section control, farmers achieve lower pesticide runoff and enhanced ecosystem protection, promoting sustainable agriculture practices.

Crop Health and Yield Outcomes

Section control technology in pesticide application significantly enhances crop health by targeting only affected areas, reducing chemical exposure to healthy plants and minimizing environmental impact. Compared to traditional spraying methods, section control improves yield outcomes by maintaining optimal plant health and preventing over-application or under-application of pesticides. Studies show fields using section control experience higher productivity and lower input costs, aligning with sustainable agriculture goals.

Operator Efficiency and Ease of Use

Section control technology in precision agriculture significantly enhances operator efficiency by automatically activating and deactivating spray sections based on GPS mapping data, reducing overlap and minimizing pesticide waste compared to traditional spraying methods. This technology simplifies the application process, allowing operators to maintain consistent coverage without manual adjustments, thus lowering fatigue and the risk of human error. Operators experience improved ease of use as section control systems integrate seamlessly with existing equipment, providing real-time feedback and automated control that streamlines workflow and optimizes pesticide application accuracy.

Future Trends in Pesticide Application Technologies

Section control technology enhances pesticide application by reducing over-spraying and minimizing environmental impact compared to traditional spraying methods. Future trends emphasize integration with AI-driven sensors and GPS precision to optimize pesticide distribution in real time, improving crop health and reducing chemical usage. Autonomous drones and variable-rate application systems are expected to revolutionize pesticide delivery, offering higher accuracy and sustainable farming practices.

Related Important Terms

Automatic Section Control (ASC)

Automatic Section Control (ASC) enhances pesticide application precision by using GPS and sensor technology to activate and deactivate sprayer nozzles in real-time, reducing overlap and chemical waste compared to traditional spraying methods. This technology increases efficiency by minimizing environmental impact and lowering operational costs through targeted pesticide use across varying field conditions.

Prescription Map Spraying

Prescription map spraying in precision agriculture enhances pesticide application efficiency by targeting specific field zones based on soil variability and pest pressure, reducing overlap and chemical waste compared to traditional uniform spraying. Section control technology further optimizes this process by automatically halting pesticide release in already treated or non-target areas, minimizing environmental impact and lowering input costs.

Overlap Reduction Algorithms

Overlap reduction algorithms in Section Control technology optimize pesticide application by minimizing redundant spraying, enhancing chemical use efficiency compared to traditional methods. These algorithms leverage GPS data and machine learning models to dynamically adjust spray zones, significantly reducing overlap and environmental impact.

Nozzle-by-Nozzle Control

Nozzle-by-nozzle control in section control systems enables precise pesticide application by activating individual nozzles only where needed, reducing chemical waste and minimizing environmental impact compared to traditional spraying methods. This technology enhances crop protection efficiency and promotes sustainable farming by targeting specific areas with variable rates of pesticide, optimizing resource use and crop health.

Variable Rate Spraying (VRS)

Variable Rate Spraying (VRS) enhances pesticide application efficiency by precisely adjusting chemical dosages based on real-time field variability, reducing waste and environmental impact compared to traditional uniform section control methods. This technology optimizes input use, improves crop health, and increases yield by targeting specific areas with the appropriate amount of pesticide.

Boundary Mapping Integration

Section control technology in precision agriculture enhances pesticide application efficiency by integrating boundary mapping to precisely target field edges, minimizing overlap and chemical waste. This integration reduces environmental impact and improves crop health compared to traditional spraying methods that lack spatial accuracy.

Turn Compensation Spraying

Section control technology in precision agriculture enables turn compensation spraying by automatically adjusting spray patterns to avoid overlap and gaps during tractor turns, significantly reducing pesticide waste and environmental impact compared to traditional constant-rate spraying methods. This targeted application enhances crop protection efficiency and lowers input costs by delivering pesticides precisely where needed, improving overall sustainability in pest management.

Geo-fencing for Application Zones

Section control technology in precision agriculture leverages geo-fencing to define exact application zones, reducing pesticide overlap and minimizing chemical use compared to traditional spraying methods. This targeted approach enhances environmental sustainability and cost-efficiency by applying pesticides only where needed based on GPS-defined boundaries.

ISOBUS Compatibility

Section control technology in pesticide application leverages ISOBUS compatibility to enable precise, automated control of spray sections, reducing overlap and minimizing chemical waste compared to traditional spraying methods. This integration enhances operational efficiency by allowing seamless communication between machinery and implements, optimizing pesticide use while supporting sustainable agricultural practices.

Pulse Width Modulation (PWM) Sprayers

Section control enhances pesticide application by using GPS and sensors to activate sprayer sections only when needed, reducing overlap and chemical waste; PWM sprayers further optimize this process by precisely regulating nozzle pressure and flow rate, ensuring uniform droplet size and improved coverage efficiency compared to traditional constant-flow spraying methods. PWM technology enables real-time adjustments for variable application rates, increasing input savings and minimizing environmental impact while maintaining effective pest control.

Section Control vs Traditional Spraying for Pesticide Application Infographic

agridif.com

agridif.com