Section control in pesticide spraying enhances precision agriculture by targeting only specific areas that require treatment, reducing chemical waste and environmental impact. Whole boom application sprays uniformly across the entire field, which can lead to over-application and increased input costs. Implementing section control technology optimizes pesticide use, improves crop health, and supports sustainable farming practices.

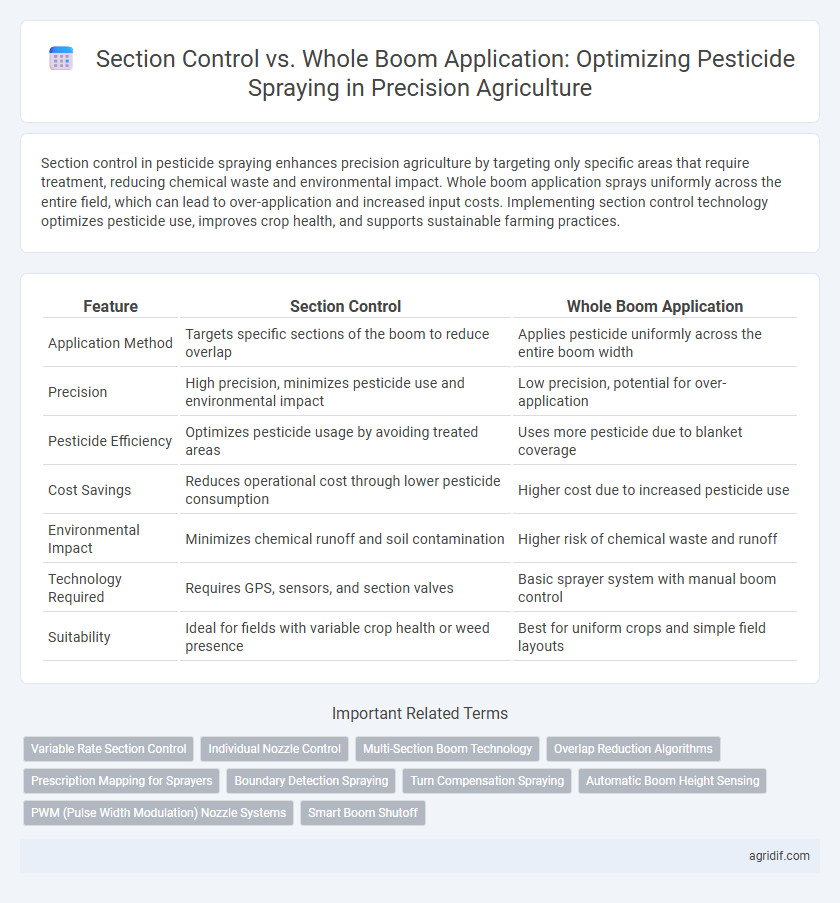

Table of Comparison

| Feature | Section Control | Whole Boom Application |

|---|---|---|

| Application Method | Targets specific sections of the boom to reduce overlap | Applies pesticide uniformly across the entire boom width |

| Precision | High precision, minimizes pesticide use and environmental impact | Low precision, potential for over-application |

| Pesticide Efficiency | Optimizes pesticide usage by avoiding treated areas | Uses more pesticide due to blanket coverage |

| Cost Savings | Reduces operational cost through lower pesticide consumption | Higher cost due to increased pesticide use |

| Environmental Impact | Minimizes chemical runoff and soil contamination | Higher risk of chemical waste and runoff |

| Technology Required | Requires GPS, sensors, and section valves | Basic sprayer system with manual boom control |

| Suitability | Ideal for fields with variable crop health or weed presence | Best for uniform crops and simple field layouts |

Introduction to Precision Agriculture in Pesticide Spraying

Section control technology in precision agriculture allows for targeted pesticide application by activating and deactivating individual boom sections, minimizing overlap and reducing chemical use. Whole boom application sprays continuously across the entire boom width, often leading to excess pesticide use and increased environmental impact. Implementing section control enhances efficiency, lowers costs, and supports sustainable farming practices by precisely matching pesticide delivery to crop needs.

Understanding Section Control Technology

Section control technology in precision agriculture enhances pesticide spraying efficiency by activating or deactivating spray nozzles based on GPS-detected field zones, reducing overlap and chemical waste. This technology enables targeted application only on needed sections, optimizing input use and minimizing environmental impact compared to whole boom application, which sprays continuously across the entire width. Implementing section control improves cost-effectiveness and supports sustainable farming practices by precisely managing pesticide distribution.

Overview of Whole Boom Application

Whole Boom Application distributes pesticides uniformly across the entire width of the boom without segmenting control, ensuring consistent coverage over the target area. This method simplifies equipment operation and reduces downtime caused by frequent switching but may lead to higher chemical usage and increased environmental impact due to lack of precise targeting. Despite its straightforward design, Whole Boom Application is less efficient than Section Control in minimizing overlap and optimizing input costs.

Key Differences Between Section Control and Whole Boom Application

Section control in pesticide spraying targets individual boom sections to reduce overlap and minimize chemical waste, enhancing application efficiency and environmental protection. Whole boom application sprays pesticides uniformly across the entire boom width, often leading to over-application in certain areas and increased input costs. Precision agriculture leverages section control technology to optimize spray patterns based on field variability, improving crop health and reducing runoff risk compared to whole boom methods.

Impact on Pesticide Usage Efficiency

Section control technology in pesticide spraying significantly enhances pesticide usage efficiency by targeting specific field zones, reducing overlap, and minimizing waste compared to whole boom application methods. By activating only necessary spray sections based on real-time GPS data, section control decreases pesticide consumption by up to 30%, promoting cost savings and environmental sustainability. Whole boom application, while simpler, often leads to excessive pesticide use due to uniform coverage regardless of crop variability, resulting in higher operational expenses and increased chemical runoff risks.

Economic Benefits of Section Control vs Whole Boom

Section control technology in pesticide spraying significantly reduces input costs by minimizing overlap and preventing over-application on treated areas, leading to substantial savings on chemicals. Whole boom application typically results in unnecessary pesticide use, increasing operational expenses and environmental impact. Implementing section control enhances cost-efficiency and promotes sustainable farming practices by optimizing resource utilization.

Environmental Implications and Sustainability

Section control in pesticide spraying minimizes chemical usage by targeting only specific crop areas, reducing environmental contamination and runoff compared to whole boom application, which sprays uniformly across the entire field regardless of need. This precision reduces pesticide drift, lowers the risk of harming non-target organisms, and limits soil and water pollution, promoting overall ecosystem health. Sustainable pest management benefits from section control technology as it enhances resource efficiency, decreases chemical inputs, and aligns with integrated pest management (IPM) principles for long-term agricultural resilience.

Technology Requirements for Implementation

Section control technology for pesticide spraying requires advanced GPS guidance systems, sensors, and automated valve control to precisely manage spray sections, reducing overlap and chemical waste. Whole boom application systems operate with uniform spray output along the entire boom but demand less sophisticated technology, primarily relying on manual or basic automated controls. Implementing section control necessitates integrating real-time data processing, communication modules, and precision actuators to enable dynamic on/off section management during field operations.

Real-World Case Studies and Results

Section control technology in pesticide spraying reduces chemical waste by targeting only infested areas, demonstrated in a 2023 Iowa cornfield study which recorded a 25% reduction in pesticide use compared to whole boom application. Real-world case studies from Brazil's soybean fields reveal that section control increases application accuracy, resulting in a 30% decrease in crop damage and a 15% boost in yield. These findings underscore precision agriculture's economic and environmental benefits by optimizing pesticide distribution based on field variability.

Future Trends in Precision Pesticide Application

Section control technology enhances precision pesticide application by targeting specific field zones, significantly reducing chemical usage and environmental impact compared to whole boom application. Future trends include integration of AI-driven sensors and GPS mapping, enabling real-time adjustments and variable rate spraying tailored to crop health and pest distribution. Advancements in drone and autonomous vehicle spray systems will further optimize efficiency and accuracy, promoting sustainable agriculture practices.

Related Important Terms

Variable Rate Section Control

Variable Rate Section Control (VRSC) in precision agriculture enhances pesticide efficiency by selectively activating spray sections based on real-time field variability, reducing chemical overlap and minimizing environmental impact. Compared to whole boom application, VRSC significantly lowers input costs and optimizes crop health by precisely targeting areas needing treatment rather than uniformly spraying the entire field.

Individual Nozzle Control

Individual nozzle control in precision agriculture enhances pesticide spraying accuracy by targeting specific sections of the field, reducing chemical waste and environmental impact compared to whole boom application. This technology optimizes spray patterns, minimizes overlap, and maximizes efficacy through real-time adjustments based on field conditions and crop variability.

Multi-Section Boom Technology

Multi-Section Boom Technology enhances pesticide application accuracy by enabling section control that targets specific field zones, reducing overlap and chemical waste compared to whole boom application. This precision increases environmental sustainability and lowers input costs while maintaining optimal crop protection.

Overlap Reduction Algorithms

Section control technology in pesticide spraying reduces overlap by activating and deactivating spray nozzles based on GPS and field boundary data, enhancing efficiency and minimizing chemical waste. Overlap reduction algorithms optimize boom sections in real-time, ensuring accurate, uniform application while preventing excessive pesticide use and environmental impact.

Prescription Mapping for Sprayers

Section control in pesticide spraying uses prescription mapping to target specific field zones, reducing chemical overlap and minimizing environmental impact. Whole boom application applies pesticides uniformly across the entire field, often leading to higher input costs and increased risk of over-application without the benefits of tailored prescription data integration.

Boundary Detection Spraying

Section control technology in precision agriculture significantly reduces pesticide overlap and drift by activating sprayer nozzles only over detected field boundaries, enhancing efficiency and minimizing chemical waste. Whole boom application lacks this targeted approach, often resulting in excessive pesticide use outside crop zones and increased environmental impact.

Turn Compensation Spraying

Turn Compensation Spraying within Section Control technology minimizes pesticide overlap on curved field sections by automatically shutting off outer nozzles, enhancing chemical use efficiency and reducing environmental impact compared to Whole Boom Application, which lacks targeted nozzle control. This precise adjustment optimizes spray distribution during turns, resulting in cost savings and improved crop protection.

Automatic Boom Height Sensing

Automatic boom height sensing enhances section control by precisely adjusting spray nozzles in real-time to maintain optimal distance from the crop canopy, reducing chemical waste and minimizing drift. Whole boom application lacks this dynamic adjustment, often leading to uneven coverage and increased pesticide usage.

PWM (Pulse Width Modulation) Nozzle Systems

PWM nozzle systems enable precise section control in pesticide spraying by modulating flow rates through rapid on/off pulsing, reducing chemical waste and over-application compared to whole boom application. This technology enhances spray accuracy and uniformity, improving crop protection efficiency while minimizing environmental impact.

Smart Boom Shutoff

Smart Boom Shutoff technology enhances Section Control by automatically deactivating specific sprayer boom sections when overlapping previously treated areas, reducing pesticide waste and minimizing environmental impact. This precision approach contrasts with Whole Boom Application, which often leads to uniform spraying regardless of crop variability, resulting in higher chemical use and lower efficiency.

Section Control vs Whole Boom Application for pesticide spraying Infographic

agridif.com

agridif.com