Telemetry monitoring provides real-time data on machinery performance, enabling proactive maintenance and reducing downtime in precision agriculture. Manual equipment checks rely on scheduled inspections, which can miss early signs of wear and result in unexpected failures. Using telemetry enhances efficiency by delivering continuous insights that improve decision-making and machine longevity.

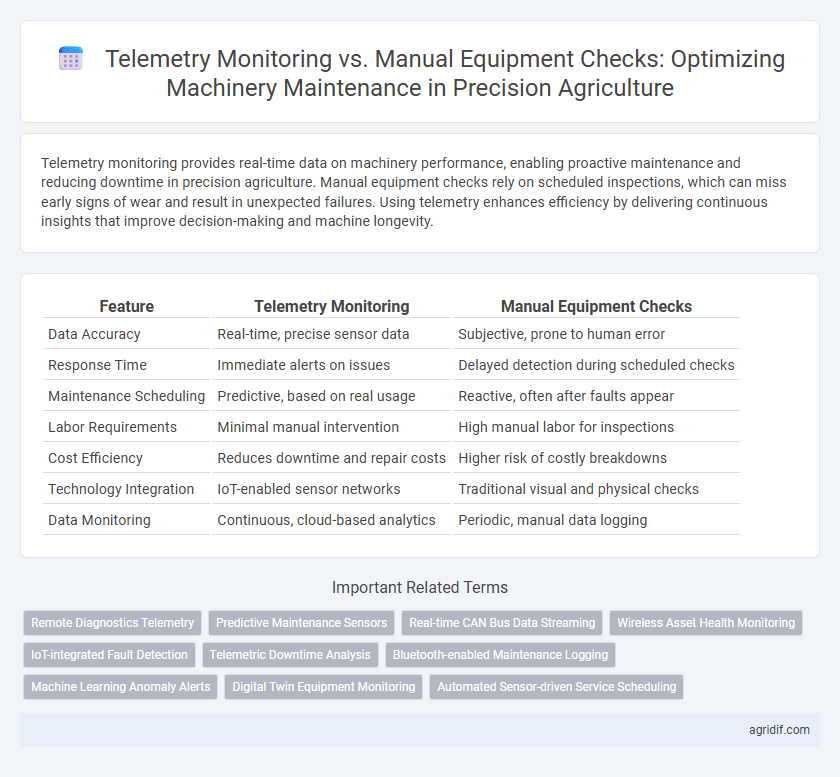

Table of Comparison

| Feature | Telemetry Monitoring | Manual Equipment Checks |

|---|---|---|

| Data Accuracy | Real-time, precise sensor data | Subjective, prone to human error |

| Response Time | Immediate alerts on issues | Delayed detection during scheduled checks |

| Maintenance Scheduling | Predictive, based on real usage | Reactive, often after faults appear |

| Labor Requirements | Minimal manual intervention | High manual labor for inspections |

| Cost Efficiency | Reduces downtime and repair costs | Higher risk of costly breakdowns |

| Technology Integration | IoT-enabled sensor networks | Traditional visual and physical checks |

| Data Monitoring | Continuous, cloud-based analytics | Periodic, manual data logging |

Introduction to Machinery Maintenance in Precision Agriculture

Telemetry monitoring in precision agriculture enables real-time data collection on machinery performance, reducing the risk of unexpected breakdowns and optimizing maintenance schedules. Manual equipment checks rely on scheduled physical inspections, which can miss subtle signs of wear or inefficiency. Integrating telemetry systems enhances predictive maintenance, improving machinery lifespan and operational efficiency in agricultural operations.

Understanding Telemetry Monitoring Systems

Telemetry monitoring systems in precision agriculture utilize real-time data transmission from sensors embedded in machinery to track performance metrics such as engine temperature, fuel levels, and operational hours. These advanced systems enable proactive maintenance by detecting anomalies early, reducing equipment downtime and extending machinery lifespan. Compared to manual equipment checks, telemetry monitoring increases accuracy and efficiency by continuously providing actionable insights without interrupting farm operations.

Manual Equipment Checks: Traditional Approaches

Manual equipment checks in precision agriculture involve technicians physically inspecting machinery components such as engines, hydraulics, and sensors to identify wear, leaks, or malfunctions. This traditional approach relies on scheduled maintenance routines and operator experience to detect issues before they cause breakdowns, ensuring machinery reliability. Despite being labor-intensive, manual inspections provide immediate tactile feedback and allow for on-the-spot adjustments that telemetry systems may not capture.

Benefits of Telemetry Monitoring for Agricultural Equipment

Telemetry monitoring for agricultural equipment enhances precision agriculture by providing real-time data on machinery performance, enabling proactive maintenance and reducing downtime. Sensors and GPS technology continuously track equipment health, fuel consumption, and operational efficiency, leading to improved decision-making and resource management. This technological approach minimizes manual labor, decreases maintenance costs, and extends the lifespan of machinery compared to traditional manual equipment checks.

Limitations of Manual Maintenance Practices

Manual equipment checks in precision agriculture often suffer from inconsistent inspection intervals and human error, leading to delayed identification of machinery faults. These limitations increase the risk of unexpected breakdowns, reducing operational efficiency and escalating repair costs. Without real-time data, manual maintenance lacks the predictive capabilities essential for proactive machinery management in modern agricultural practices.

Real-Time Data Insights vs. Periodic Assessments

Telemetry monitoring in precision agriculture provides real-time data insights on machinery performance, enabling immediate detection of faults and predictive maintenance to minimize downtime. Manual equipment checks rely on periodic assessments that may miss early signs of wear and lead to unexpected failures. Leveraging telemetry enhances operational efficiency by continuously tracking equipment health, reducing maintenance costs, and optimizing machinery lifespan.

Cost Efficiency: Telemetry Monitoring vs. Manual Checks

Telemetry monitoring significantly reduces labor costs by providing real-time data on equipment performance, enabling predictive maintenance that minimizes unexpected breakdowns and costly repairs. Manual equipment checks, while thorough, require substantial time and manpower, increasing operational expenses and the risk of delayed issue detection. Implementing telemetry systems enhances cost efficiency by optimizing maintenance schedules and extending machinery lifespan through continuous remote monitoring.

Impact on Equipment Lifespan and Downtime

Telemetry monitoring enables real-time data collection on machinery performance, significantly reducing unexpected breakdowns and extending equipment lifespan through predictive maintenance. Manual equipment checks, while essential, often detect issues later, leading to increased downtime and accelerated wear. Integrating telemetry systems with routine inspections optimizes maintenance schedules, maximizes operational efficiency, and minimizes costly downtime in precision agriculture.

Integrating Telemetry with Farm Management Systems

Integrating telemetry monitoring with farm management systems enables real-time data analysis for predictive maintenance, reducing machinery downtime and operational costs. Telemetry provides continuous machine performance metrics such as engine hours, fuel consumption, and hydraulic pressure, allowing for timely alerts and proactive interventions. Combining these insights with manual equipment checks enhances maintenance accuracy and supports data-driven decision-making in precision agriculture.

Future Trends: The Evolution of Machinery Maintenance in Precision Agriculture

Telemetry monitoring in precision agriculture leverages real-time data transmission from machinery sensors to enable predictive maintenance, reducing downtime and optimizing equipment performance. Future trends indicate increased integration of AI-driven analytics and IoT connectivity, facilitating automated diagnostics and remote troubleshooting. This evolution surpasses manual equipment checks by enhancing accuracy, efficiency, and proactive maintenance strategies in agricultural machinery management.

Related Important Terms

Remote Diagnostics Telemetry

Telemetry monitoring enables real-time remote diagnostics of agricultural machinery, significantly reducing downtime by promptly detecting equipment malfunctions and performance issues. This technology leverages sensor data and wireless communication to provide precise maintenance alerts, outperforming traditional manual equipment checks in accuracy and response speed.

Predictive Maintenance Sensors

Predictive maintenance sensors in telemetry monitoring enable real-time data collection on machinery conditions, reducing downtime by anticipating failures before they occur. Manual equipment checks lack the continuous insight provided by these sensors, leading to less efficient maintenance schedules and increased risk of unexpected breakdowns.

Real-time CAN Bus Data Streaming

Real-time CAN bus data streaming in telemetry monitoring provides continuous, precise insights into machinery performance, enabling proactive maintenance and reducing downtime. This contrasts with manual equipment checks, which rely on periodic inspections that can miss early warning signs and delay critical interventions.

Wireless Asset Health Monitoring

Wireless asset health monitoring enables real-time telemetry for precision agriculture machinery, providing continuous data on equipment performance and early detection of faults. This technology reduces downtime and maintenance costs compared to traditional manual equipment checks by delivering automated alerts and detailed diagnostics remotely.

IoT-integrated Fault Detection

IoT-integrated telemetry monitoring enables real-time fault detection in agricultural machinery, significantly reducing downtime and maintenance costs compared to manual equipment checks. Continuous data collection and predictive analytics improve equipment reliability by identifying performance anomalies before they lead to critical failures.

Telemetric Downtime Analysis

Telemetric downtime analysis enables real-time monitoring of agricultural machinery performance, allowing for immediate detection of faults and predictive maintenance that minimizes unplanned stoppages. This data-driven approach enhances equipment reliability and operational efficiency compared to traditional manual equipment checks, which rely on periodic inspections and often miss early warning signs of mechanical issues.

Bluetooth-enabled Maintenance Logging

Bluetooth-enabled maintenance logging in telemetry monitoring provides real-time data collection and automatic updates on machinery performance, reducing human error and downtime compared to manual equipment checks. This technology enhances precision agriculture by enabling timely maintenance through wireless connectivity, ensuring optimal machine efficiency and prolonging equipment lifespan.

Machine Learning Anomaly Alerts

Machine learning anomaly alerts in telemetry monitoring enable real-time detection of equipment malfunctions, reducing downtime and maintenance costs compared to manual checks. These alerts analyze sensor data continuously, providing predictive insights that optimize machinery performance and extend asset lifespan.

Digital Twin Equipment Monitoring

Digital Twin equipment monitoring leverages real-time telemetry data to provide continuous insights into machinery performance and predictive maintenance needs, significantly reducing downtime compared to manual equipment checks. This digital replication of physical assets enables precise fault detection, optimizes operational efficiency, and lowers maintenance costs in precision agriculture machinery management.

Automated Sensor-driven Service Scheduling

Automated sensor-driven service scheduling in telemetry monitoring enables real-time data collection on machinery performance, predicting maintenance needs with high accuracy to prevent breakdowns. This technology surpasses manual equipment checks by reducing downtime and optimizing repair intervals based on precise sensor analytics and usage patterns.

Telemetry Monitoring vs Manual Equipment Checks for Machinery Maintenance Infographic

agridif.com

agridif.com