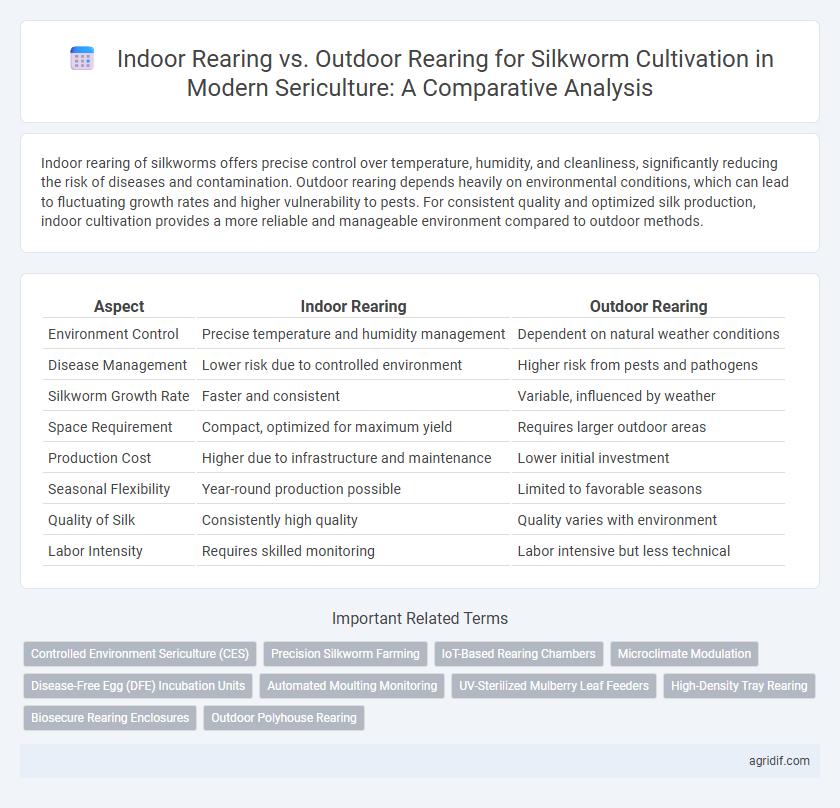

Indoor rearing of silkworms offers precise control over temperature, humidity, and cleanliness, significantly reducing the risk of diseases and contamination. Outdoor rearing depends heavily on environmental conditions, which can lead to fluctuating growth rates and higher vulnerability to pests. For consistent quality and optimized silk production, indoor cultivation provides a more reliable and manageable environment compared to outdoor methods.

Table of Comparison

| Aspect | Indoor Rearing | Outdoor Rearing |

|---|---|---|

| Environment Control | Precise temperature and humidity management | Dependent on natural weather conditions |

| Disease Management | Lower risk due to controlled environment | Higher risk from pests and pathogens |

| Silkworm Growth Rate | Faster and consistent | Variable, influenced by weather |

| Space Requirement | Compact, optimized for maximum yield | Requires larger outdoor areas |

| Production Cost | Higher due to infrastructure and maintenance | Lower initial investment |

| Seasonal Flexibility | Year-round production possible | Limited to favorable seasons |

| Quality of Silk | Consistently high quality | Quality varies with environment |

| Labor Intensity | Requires skilled monitoring | Labor intensive but less technical |

Introduction to Silkworm Rearing Methods

Indoor rearing of silkworms offers a controlled environment with regulated temperature, humidity, and cleanliness, enhancing larval growth and reducing disease incidence. Outdoor rearing relies on natural conditions and is cost-effective but exposes larvae to variable weather, predators, and microbial threats, affecting yield consistency. Selection of rearing methods depends on available resources, scale of production, and desired quality of silk output in sericulture.

Key Differences: Indoor vs Outdoor Rearing

Indoor rearing of silkworms offers controlled temperature, humidity, and light conditions, ensuring higher survival rates and consistent silk quality compared to outdoor rearing. Outdoor rearing depends heavily on environmental factors, making silkworms more vulnerable to pests, diseases, and climatic fluctuations. Controlled indoor environments facilitate optimized feeding schedules and reduce exposure to pollutants, enhancing overall cocoon yield and silk fiber uniformity.

Environmental Control in Silkworm Cultivation

Indoor rearing of silkworms allows precise environmental control, maintaining optimal temperature, humidity, and light conditions to enhance cocoon quality and reduce disease risk. Outdoor rearing relies on natural climatic conditions, which can introduce variability and stress, affecting silkworm growth and silk yield. Controlled indoor environments support consistent brood management and improve overall productivity in sericulture operations.

Disease Management: Indoor and Outdoor Comparisons

Indoor rearing of silkworms offers superior disease management by providing controlled environmental conditions that limit pathogen exposure and facilitate timely sanitation practices. Outdoor rearing exposes silkworms to variable weather and higher risk of infection from fungal, bacterial, and viral agents due to uncontrollable humidity and temperature fluctuations. Implementing strict hygiene protocols indoors significantly reduces disease outbreaks, enhancing cocoon yield and quality compared to outdoor cultivation.

Impact on Cocoon Quality and Yield

Indoor rearing of silkworms provides controlled temperature, humidity, and light, resulting in higher cocoon quality with uniform size and reduced contamination. Outdoor rearing exposes silkworms to fluctuating environmental conditions, leading to variable cocoon yields and increased risk of diseases and predation. Consistent indoor environments enhance silk filament length and tensile strength, directly improving both yield and commercial value.

Labor and Resource Requirements

Indoor rearing of silkworms demands higher labor intensity and increased energy resources for controlled temperature, humidity, and cleanliness, ensuring optimal growth conditions. Outdoor rearing relies more on natural environmental factors, reducing energy consumption but often requiring more frequent manual monitoring to manage delays or pest threats. Resource allocation in indoor systems is heavier due to artificial climate control, while outdoor cultivation depends significantly on seasonal weather patterns and natural vegetation as feed.

Cost Analysis: Indoor vs Outdoor Rearing

Indoor rearing of silkworms involves higher initial investments due to controlled environment infrastructure, including temperature and humidity regulation systems, leading to increased operational costs compared to outdoor rearing. Outdoor rearing reduces overhead by utilizing natural climate conditions but exposes silkworms to environmental fluctuations, affecting yield consistency and potentially increasing loss rates. Cost analysis reveals indoor rearing offers higher productivity and quality control at greater expense, while outdoor rearing provides cost savings with variable output and risk factors.

Sustainability and Eco-Friendliness

Indoor rearing of silkworms ensures controlled environmental conditions, reducing the risk of disease and pesticide exposure, which enhances sustainability and minimizes ecological impact. Outdoor rearing leverages natural sunlight and airflow, promoting eco-friendliness through reduced energy consumption and fostering biodiversity in mulberry plantations. Integrating organic mulberry cultivation with these rearing methods further supports sustainable sericulture practices by preserving soil health and reducing chemical inputs.

Challenges and Solutions in Each Method

Indoor rearing of silkworms faces challenges such as maintaining optimal temperature, humidity, and sanitation to prevent diseases, which can be addressed through controlled environment systems and regular monitoring protocols. Outdoor rearing encounters difficulties like fluctuating weather conditions, pest attacks, and natural predators; solutions include using protective netting, integrated pest management, and selecting resilient silkworm hybrids. Both methods require tailored management practices to maximize cocoon yield and quality under their specific environmental constraints.

Choosing the Best Rearing Technique for Optimal Output

Indoor rearing for silkworm cultivation offers controlled environmental conditions that boost larval health and cocoon quality, minimizing risks from predators and weather fluctuations. Outdoor rearing exposes silkworms to natural climatic variations and mulberry leaf availability, which may enhance robustness but can lead to inconsistent yields. Selecting the best technique depends on balancing resource availability, environmental control, and production goals to maximize silk output and quality.

Related Important Terms

Controlled Environment Sericulture (CES)

Indoor rearing in Controlled Environment Sericulture (CES) optimizes silkworm cultivation by regulating temperature, humidity, and light, resulting in higher cocoon yield and improved silk quality compared to outdoor rearing. CES minimizes exposure to pests, diseases, and environmental fluctuations, enhancing larval survival rates and ensuring consistent silk production.

Precision Silkworm Farming

Indoor rearing for silkworm cultivation enhances precision silkworm farming by providing controlled temperature, humidity, and light conditions that optimize larval development and cocoon quality. Outdoor rearing, while cost-effective, exposes silkworms to environmental fluctuations and pests, limiting the ability to maintain consistent production standards.

IoT-Based Rearing Chambers

IoT-based rearing chambers enhance indoor sericulture by providing precise control over temperature, humidity, and light, optimizing silkworm growth and cocoon quality while reducing environmental risks compared to traditional outdoor rearing. These smart chambers enable real-time monitoring and automated adjustments, leading to increased yield, disease management, and resource efficiency in silkworm cultivation.

Microclimate Modulation

Indoor rearing of silkworms allows precise microclimate modulation by controlling temperature, humidity, and ventilation, which enhances larval growth and silk quality. Outdoor rearing depends on natural environmental conditions that fluctuate, often leading to variable microclimates and inconsistent silk production.

Disease-Free Egg (DFE) Incubation Units

Disease-Free Egg (DFE) Incubation Units in indoor rearing environments provide controlled temperature, humidity, and sanitation that significantly reduce silkworm disease outbreaks compared to outdoor rearing. This sterile, monitored setup enhances silk yield quality and consistency by ensuring higher egg hatch rates free from pathogens.

Automated Moulting Monitoring

Automated moulting monitoring in indoor rearing of silkworms enhances precise environmental control and real-time data collection, boosting cocoon quality and reducing mortality rates compared to outdoor methods. Indoor systems leverage sensors and AI algorithms to track larval development stages, enabling optimized feeding schedules and seamless intervention during critical moulting phases.

UV-Sterilized Mulberry Leaf Feeders

UV-sterilized mulberry leaf feeders enhance indoor rearing of silkworms by significantly reducing microbial contamination, leading to higher larval survival rates and improved silk yield. In comparison, outdoor rearing exposes silkworms to environmental pathogens and inconsistent leaf quality, which can hinder growth and lower productivity.

High-Density Tray Rearing

High-density tray rearing for silkworm cultivation indoors enables controlled environmental conditions, resulting in higher yield and consistent larval development compared to outdoor rearing, which is susceptible to weather fluctuations and pests. Indoor systems enhance disease management and optimize space utilization, making them more efficient for large-scale sericulture operations.

Biosecure Rearing Enclosures

Biosecure rearing enclosures in indoor silkworm cultivation significantly reduce contamination risks by controlling temperature, humidity, and exposure to pathogens, enhancing larval survival and silk quality. Outdoor rearing lacks such stringent biosecurity measures, making silkworms more vulnerable to pests, diseases, and environmental fluctuations, which often result in lower yields and inconsistent silk production.

Outdoor Polyhouse Rearing

Outdoor polyhouse rearing for silkworm cultivation provides a controlled environment that optimizes temperature, humidity, and ventilation, enhancing larval growth and cocoon quality. This method reduces exposure to pests and diseases compared to traditional open-field outdoor rearing, resulting in higher productivity and consistent silk yield.

Indoor rearing vs Outdoor rearing for silkworm cultivation Infographic

agridif.com

agridif.com