Disinfection in sericulture rearing rooms is crucial for preventing diseases and promoting healthy silkworm growth, with bleaching powder and formalin being common agents used. Bleaching powder offers strong oxidizing properties, effectively eliminating pathogens and organic matter, while formalin provides a potent antimicrobial effect but requires careful handling due to its toxicity. Bleaching powder is generally favored for its cost-effectiveness and ease of use, whereas formalin's use is limited to controlled environments where safety protocols are strictly observed.

Table of Comparison

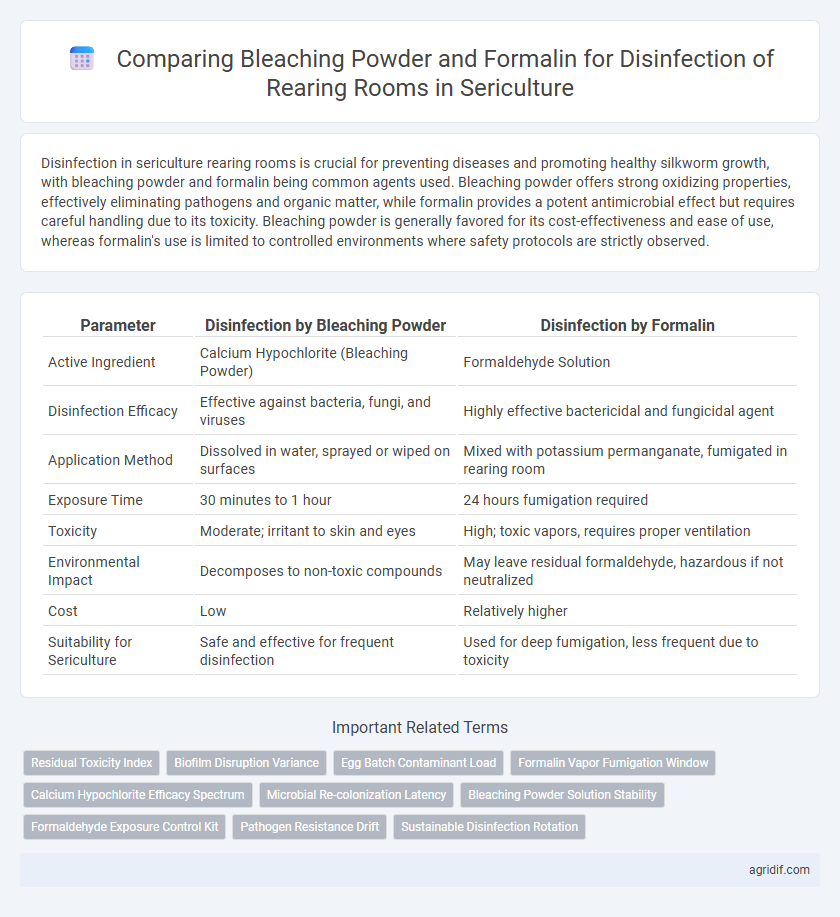

| Parameter | Disinfection by Bleaching Powder | Disinfection by Formalin |

|---|---|---|

| Active Ingredient | Calcium Hypochlorite (Bleaching Powder) | Formaldehyde Solution |

| Disinfection Efficacy | Effective against bacteria, fungi, and viruses | Highly effective bactericidal and fungicidal agent |

| Application Method | Dissolved in water, sprayed or wiped on surfaces | Mixed with potassium permanganate, fumigated in rearing room |

| Exposure Time | 30 minutes to 1 hour | 24 hours fumigation required |

| Toxicity | Moderate; irritant to skin and eyes | High; toxic vapors, requires proper ventilation |

| Environmental Impact | Decomposes to non-toxic compounds | May leave residual formaldehyde, hazardous if not neutralized |

| Cost | Low | Relatively higher |

| Suitability for Sericulture | Safe and effective for frequent disinfection | Used for deep fumigation, less frequent due to toxicity |

Importance of Disinfection in Silkworm Rearing Rooms

Effective disinfection in silkworm rearing rooms prevents the spread of pathogens such as bacteria, fungi, and viruses that can severely impact silkworm health and silk yield. Bleaching powder provides strong oxidizing action, rapidly eliminating contaminants, while formalin acts as a potent disinfectant with longer residual effects, controlling microbial growth over extended periods. Selecting the appropriate disinfectant ensures optimal silkworm growth conditions and maximizes cocoon quality by maintaining a hygienic rearing environment.

Overview of Bleaching Powder and Formalin as Disinfectants

Bleaching powder, containing calcium hypochlorite, acts as a strong oxidizing agent that effectively eliminates bacteria, fungi, and viruses in sericulture rearing rooms by releasing chlorine upon contact with moisture. Formalin, a solution of formaldehyde in water, serves as a potent disinfectant and fumigant that disrupts microbial cellular functions, providing long-lasting sterilization effects critical for preventing silkworm diseases. Both agents are essential in maintaining hygiene, with bleaching powder favored for surface disinfection and formalin preferred for fumigation and controlling airborne pathogens in sericulture environments.

Mechanism of Action: Bleaching Powder vs Formalin

Bleaching powder acts as a strong oxidizing agent, releasing chlorine that disrupts cellular components of pathogens through oxidation, effectively killing bacteria and fungi in sericulture rearing rooms. Formalin, an aqueous solution of formaldehyde, works by alkylating amino groups in proteins and nucleic acids, leading to microbial protein denaturation and inhibition of replication. The oxidative damage caused by bleaching powder provides rapid disinfection, while formalin's protein cross-linking offers prolonged antimicrobial effects.

Preparation and Application Methods

Bleaching powder disinfection in sericulture involves mixing 1-2 grams of powder in a liter of water to create a 0.1-0.2% solution, which is sprayed thoroughly on walls and floors of the rearing room, followed by airing for 1-2 hours before silkworm introduction. Formalin disinfection requires preparing a 0.1-0.2% formalin solution by mixing 1-2 milliliters of formalin with 1 liter of water, often combined with potassium permanganate to generate formaldehyde gas for fumigation, ensuring complete sealing of the room for 6-8 hours. Bleaching powder is preferred for its cost-effectiveness and ease of application, while formalin offers deeper penetration and better control of fungal pathogens in high-humidity environments.

Effectiveness Against Common Sericulture Pathogens

Bleaching powder exhibits strong broad-spectrum antimicrobial activity, effectively reducing bacterial and fungal loads commonly found in sericulture rearing rooms, including pathogens like Bacillus thuringiensis and Fusarium spp. Formalin, while potent against fungal spores and certain bacteria, may be less effective against bacterial pathogens and poses higher toxicity risks to both silkworms and handlers. Optimal disinfection protocols in sericulture prioritize bleaching powder for comprehensive pathogen control with safer application profiles.

Impact on Silkworm Health and Cocoon Yield

Bleaching powder effectively disinfects rearing rooms by eliminating pathogens without leaving harmful residues, promoting healthier silkworm growth and higher cocoon yield. Formalin, while a strong disinfectant, can emit toxic fumes that may stress silkworms, potentially reducing their vitality and cocoon production. Optimal silkworm health and cocoon yield are better maintained through bleaching powder use due to its safer, residue-controlled disinfectant properties.

Safety Precautions and Handling Guidelines

Bleaching powder offers effective disinfection in sericulture rearing rooms with lower toxicity compared to formalin, reducing health risks for workers. Proper ventilation, use of personal protective equipment (PPE) such as gloves and masks, and avoiding direct skin contact are essential safety measures when handling both disinfectants. Formalin requires stricter handling guidelines due to its carcinogenic properties, necessitating limited exposure time and thorough training to ensure safe use.

Environmental Considerations and Residue Management

Bleaching powder effectively disinfects rearing rooms with rapid action and leaves calcium chloride residues that are environmentally benign and easily managed through regular cleaning. Formalin, although a potent disinfectant, releases formaldehyde vapors that pose health hazards and require stringent ventilation protocols to minimize environmental and occupational risks. Proper residue management after bleaching powder use ensures minimal ecological impact, whereas formalin demands specialized handling and disposal to prevent soil and air contamination.

Cost-Effectiveness Analysis in Routine Sericulture

Bleaching powder offers a more cost-effective solution for disinfection in sericulture rearing rooms due to its lower price and ease of availability compared to formalin. While formalin provides strong antimicrobial properties, its higher cost and potential health hazards increase long-term expenses and safety risks in routine sericulture. Incorporating bleaching powder ensures affordable, efficient hygiene management, optimizing overall sericulture production costs.

Recommendations for Optimal Disinfection Practices

Bleaching powder is recommended for rearing room disinfection due to its strong oxidizing properties, rapid microbial elimination, and cost-effectiveness compared to formalin. Formalin, while effective in fungal and bacterial control, poses health risks such as respiratory irritation and requires strict ventilation during application. Optimal practices favor bleaching powder at a concentration of 3-5% with thorough room airing post-application to ensure safety and maintain a pathogen-free environment.

Related Important Terms

Residual Toxicity Index

Bleaching powder exhibits a lower Residual Toxicity Index compared to formalin, making it safer for use in sericulture rearing rooms by minimizing harmful chemical residues. Formalin, while effective as a disinfectant, tends to leave higher residual toxicity, posing potential risks to silkworm health and cocoons during the rearing process.

Biofilm Disruption Variance

Bleaching powder exhibits superior biofilm disruption in sericulture rearing rooms by releasing free chlorine ions that effectively degrade extracellular polymeric substances, whereas formalin primarily acts as a surface disinfectant with limited penetration into biofilm matrices. Quantitative studies indicate bleaching powder reduces biofilm biomass by up to 70%, outperforming formalin's approximate 40% reduction, thereby enhancing silkworm health and minimizing pathogen persistence.

Egg Batch Contaminant Load

Bleaching powder effectively reduces egg batch contaminant load in sericulture rearing rooms through strong oxidative properties that eliminate bacteria, fungi, and viruses without leaving harmful residues. Formalin also controls microbial contamination but poses toxicity risks and requires careful handling, making bleaching powder a safer and more environmentally friendly disinfectant for maintaining egg hygiene during sericulture operations.

Formalin Vapor Fumigation Window

Formalin vapor fumigation window provides effective disinfection in sericulture rearing rooms by eliminating pathogens and pests, ensuring a pathogen-free environment for silkworms. Compared to bleaching powder, formalin offers longer-lasting sterilization with minimal residue, reducing contamination risks and promoting healthier silkworm development.

Calcium Hypochlorite Efficacy Spectrum

Calcium hypochlorite, the active component in bleaching powder, exhibits a broad-spectrum antimicrobial efficacy, effectively eliminating bacteria, fungi, and viruses in sericulture rearing rooms, ensuring a hygienic environment for silkworms. Compared to formalin, calcium hypochlorite offers rapid disinfection with lower toxicity, making it a safer and more efficient choice for controlling pathogenic contamination in sericulture facilities.

Microbial Re-colonization Latency

Bleaching powder shows a shorter microbial re-colonization latency, typically restoring microbial balance within 3-5 days, whereas formalin treatment extends this period to 7-10 days, providing prolonged microbial suppression in sericulture rearing rooms. Selecting between bleaching powder and formalin depends on the desired duration of microbial control, with formalin offering longer-lasting disinfection but requiring careful handling due to toxicity concerns.

Bleaching Powder Solution Stability

Bleaching powder solution exhibits higher stability over time compared to formalin, maintaining its disinfectant properties effectively under typical rearing room conditions for sericulture. This prolonged stability ensures consistent microbial control, reducing the frequency of solution preparation and enhancing overall rearing room hygiene management.

Formaldehyde Exposure Control Kit

Formalin effectively disinfects sericulture rearing rooms by eliminating pathogens but poses health risks due to formaldehyde exposure; using a Formaldehyde Exposure Control Kit ensures safe handling by monitoring air quality and reducing inhalation hazards. Bleaching powder offers an alternative with lower toxicity but may be less effective against certain microbes, making formalin with exposure control kits preferable for maintaining optimal hygiene and worker safety.

Pathogen Resistance Drift

Disinfection of sericulture rearing rooms with bleaching powder effectively reduces a broad spectrum of pathogens but may lead to pathogen resistance drift due to oxidative stress mechanisms. In contrast, formalin offers strong antimicrobial action with lower chances of resistance development, making it a preferred choice for long-term pathogen control in silkworm rearing environments.

Sustainable Disinfection Rotation

Bleaching powder offers effective, eco-friendly disinfection for sericulture rearing rooms by decomposing into non-toxic residues, while formalin provides strong antimicrobial action but poses health risks and environmental concerns. Implementing a sustainable disinfection rotation alternating bleaching powder and formalin reduces chemical resistance, minimizes environmental impact, and maintains a safe rearing environment for silkworms.

Disinfection by Bleaching Powder vs Formalin for Rearing Room Infographic

agridif.com

agridif.com