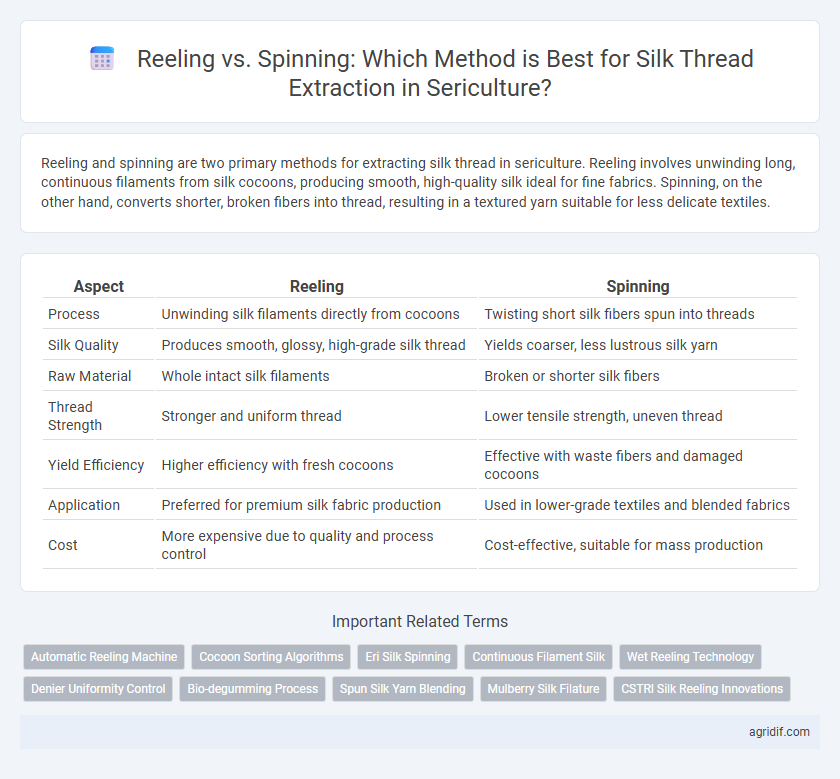

Reeling and spinning are two primary methods for extracting silk thread in sericulture. Reeling involves unwinding long, continuous filaments from silk cocoons, producing smooth, high-quality silk ideal for fine fabrics. Spinning, on the other hand, converts shorter, broken fibers into thread, resulting in a textured yarn suitable for less delicate textiles.

Table of Comparison

| Aspect | Reeling | Spinning |

|---|---|---|

| Process | Unwinding silk filaments directly from cocoons | Twisting short silk fibers spun into threads |

| Silk Quality | Produces smooth, glossy, high-grade silk thread | Yields coarser, less lustrous silk yarn |

| Raw Material | Whole intact silk filaments | Broken or shorter silk fibers |

| Thread Strength | Stronger and uniform thread | Lower tensile strength, uneven thread |

| Yield Efficiency | Higher efficiency with fresh cocoons | Effective with waste fibers and damaged cocoons |

| Application | Preferred for premium silk fabric production | Used in lower-grade textiles and blended fabrics |

| Cost | More expensive due to quality and process control | Cost-effective, suitable for mass production |

Introduction to Silk Thread Extraction

Silk thread extraction involves two primary methods: reeling and spinning, each yielding different fiber qualities and applications. Reeling extracts long, continuous filaments directly from silkworm cocoons, resulting in smooth, high-strength silk ideal for fine textiles. Spinning processes shorter, broken fibers or waste silk into yarn, producing a less lustrous but more affordable silk thread suitable for various fabric blends.

Overview of Sericulture Practices

Reeling and spinning are two primary methods for extracting silk threads in sericulture, each yielding different fiber qualities. Reeling involves unwinding silk filaments from cocoons in long, continuous strands, producing smooth, lustrous threads ideal for high-quality silk fabrics. Spinning processes shorter fibers or damaged filaments, resulting in coarser silk yarns used in blended or less refined textile products.

Defining Reeling in Silk Production

Reeling in silk production involves unwinding continuous filaments from the cocoon to create long, smooth silk threads essential for high-quality silk fabric. This process preserves the filament's length and strength, resulting in fine, lustrous silk fibers that differ from the shorter, twisted fibers obtained through spinning. By maintaining the filament's integrity, reeling produces silk threads with superior tensile properties and uniform texture, crucial for premium textile applications.

Defining Spinning in Silk Production

Spinning in silk production refers to the process of twisting shorter silk fibers into yarn or thread, unlike reeling which involves unwinding continuous filaments directly from silk cocoons. This method is utilized especially when fibers are broken or shorter, ensuring no silk is wasted and enabling the production of textured or blended silk yarns. Spun silk threads often have a softer, more matte finish compared to the glossy, smooth appearance of reeled silk.

Key Differences: Reeling vs Spinning

Reeling extracts silk thread by unwinding long filaments directly from silk cocoons, resulting in smooth and continuous fiber ideal for high-quality fabrics. Spinning, on the other hand, involves twisting shorter silk fibers together, producing a coarser yarn better suited for lower-grade textiles or mixed fabrics. Key differences include fiber length uniformity, thread strength, and fabric texture, with reeling preserving filament integrity while spinning allows use of damaged or broken fibers.

Equipment Used in Reeling and Spinning

Reeling silk involves the use of a reeling machine that carefully unwinds raw silk filaments from cocoons, preserving long continuous fibers essential for fine silk thread production. Spinning employs spinning frames or spinning wheels that twist shorter silk fibers, often derived from broken cocoons or waste, into yarn suitable for coarser textiles. The distinct equipment in reeling and spinning directly impacts the quality and texture of the silk thread produced, highlighting the importance of selecting appropriate machinery in sericulture.

Quality of Silk: Reeling vs Spinning

Reeling preserves the long, continuous filaments of silk, resulting in a smoother, stronger, and more lustrous thread compared to spinning. Spinning involves twisting shorter fibers together, which produces a coarser and less uniform thread with lower tensile strength. Therefore, silk extracted by reeling is superior in quality, ideal for high-end textiles demanding fine texture and durability.

Efficiency and Yield Comparison

Reeling silk from cocoons produces long, continuous filaments resulting in higher-quality and smoother threads with greater tensile strength, leading to superior efficiency in textile manufacturing. Spinning processes, using shorter fibers or broken filaments, typically yield lower-quality silk threads with reduced strength and increased fuzziness, impacting overall efficiency negatively. Therefore, reeling offers higher yield and better fiber utilization compared to spinning, making it the preferred method for premium silk thread production.

Sustainability and Environmental Impact

Reeling silk from cocoons preserves fiber integrity, producing smoother, stronger threads with less waste compared to spinning, which involves breaking down fibers and generates more short fibers and dust. Sustainable sericulture favors reeling because it supports fiber reuse, reduces energy consumption, and minimizes environmental pollutants released during spinning processes. Moreover, reeling decreases water usage and chemical input, contributing significantly to eco-friendly silk production.

Choosing the Best Method for Silk Thread Extraction

Reeling preserves the long, continuous filaments from silkworm cocoons, resulting in smoother, stronger silk threads ideal for high-quality textiles. Spinning processes shorter fibers from damaged or broken cocoons, producing yarns with a coarser texture suitable for less delicate fabrics. Selecting reeling or spinning depends on cocoon quality, desired thread strength, and fabric application to optimize silk thread extraction efficiency.

Related Important Terms

Automatic Reeling Machine

Automatic reeling machines sharply enhance silk thread extraction by delivering consistent tension control and high-speed processing, outperforming traditional spinning in yield and fiber quality. These machines optimize the reeling process by precisely unwinding silk filaments from cocoons, ensuring uniform thread thickness and minimizing filament breakage.

Cocoon Sorting Algorithms

Cocoon sorting algorithms critically impact the efficiency of both reeling and spinning silk thread extraction by accurately categorizing cocoons based on quality, size, and filament length, which enhances uniformity and reduces waste. Optimized sorting mechanisms improve reeling performance by selecting intact, high-quality cocoons for continuous filament extraction, while in spinning, sorted cocoons facilitate consistent staple fiber production for stronger, finer yarns.

Eri Silk Spinning

Eri silk spinning differs fundamentally from reeling as it involves twisting short staple fibers into yarn rather than continuously unwinding long silk filaments from cocoons, making it suitable for non-mulberry silks like Eri. The spinning process preserves Eri silk's unique woolly texture and thermal properties, creating a durable and warm fabric distinct from the smooth, lustrous threads obtained through reeling.

Continuous Filament Silk

Reeling extracts long, continuous filament silk from intact cocoons, preserving filament length and producing smooth, lustrous silk threads ideal for high-quality textiles. In contrast, spinning uses shorter, broken fibers from damaged or processed cocoons, resulting in weaker, less uniform threads suited for lower-grade silk products.

Wet Reeling Technology

Wet reeling technology in sericulture enhances silk thread extraction by using water to maintain filament strength and prevent breakage during the unwinding process, resulting in higher quality and more uniform silk threads compared to spinning. Wet reeling preserves the continuous filament structure, producing finer and stronger silk suitable for premium textile applications.

Denier Uniformity Control

Reeling maintains superior denier uniformity control by extracting continuous silk filaments directly from cocoons, resulting in consistent thread thickness essential for high-quality silk fabric production. Spinning, which uses shorter fibers and twists them together, often leads to greater variability in denier uniformity, affecting the smoothness and strength of the final silk yarn.

Bio-degumming Process

Reeling extracts silk threads directly from silk cocoons, preserving the fiber's smooth, continuous structure, while spinning produces yarn from shorter silk fibers after they undergo bio-degumming to remove sericin naturally. The bio-degumming process enhances fiber softness and luster by enzymatically breaking down sericin proteins, making silk threads more suitable for spinning compared to traditional chemical degumming used in reeling.

Spun Silk Yarn Blending

Spun silk yarn blending combines shorter silk fibers with other natural or synthetic fibers to create versatile, textured fabrics, contrasting with reeling that extracts long continuous filament fibers. This blending enhances durability, affordability, and design flexibility in silk textiles used in fashion and upholstery.

Mulberry Silk Filature

Reeling in Mulberry Silk Filature involves unwinding continuous filaments directly from silk cocoons, preserving fiber length and ensuring high tensile strength and smooth texture ideal for premium silk fabrics. Spinning, by contrast, processes shorter fibers or damaged cocoons by twisting fibers together, resulting in a less lustrous and coarser thread suitable for lower-grade silk products.

CSTRI Silk Reeling Innovations

CSTRI Silk Reeling Innovations have revolutionized silk thread extraction by developing advanced reeling machines that enhance filament length and uniformity, surpassing traditional spinning methods which produce shorter and less consistent fibers. These innovations significantly improve raw silk quality by minimizing filament breakage and increasing reeling efficiency, positioning CSTRI as a leader in modern sericulture technology.

Reeling vs Spinning for silk thread extraction Infographic

agridif.com

agridif.com