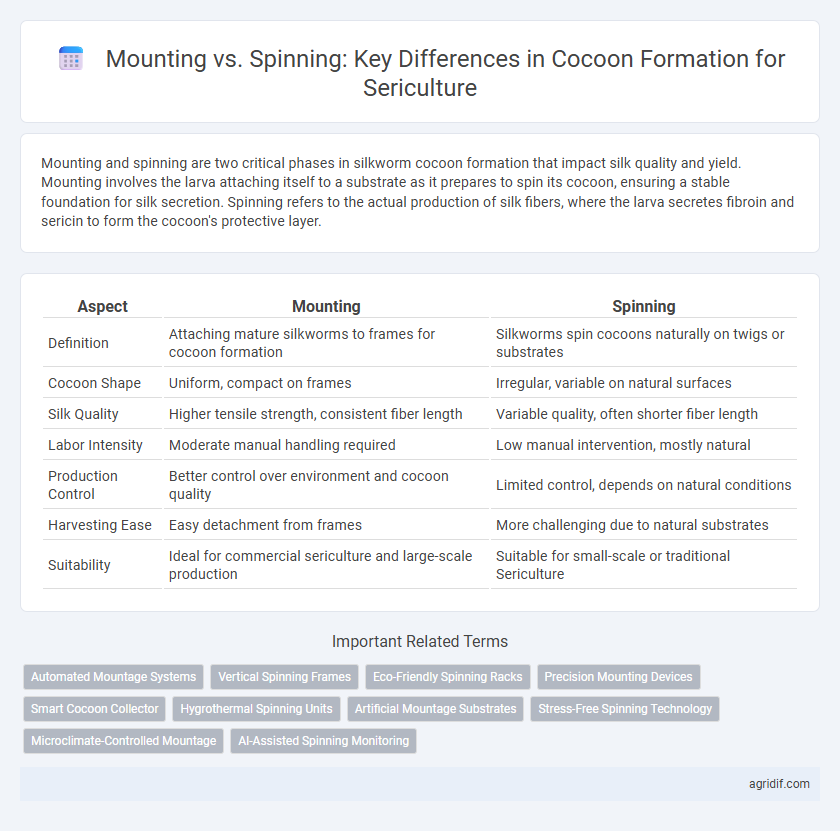

Mounting and spinning are two critical phases in silkworm cocoon formation that impact silk quality and yield. Mounting involves the larva attaching itself to a substrate as it prepares to spin its cocoon, ensuring a stable foundation for silk secretion. Spinning refers to the actual production of silk fibers, where the larva secretes fibroin and sericin to form the cocoon's protective layer.

Table of Comparison

| Aspect | Mounting | Spinning |

|---|---|---|

| Definition | Attaching mature silkworms to frames for cocoon formation | Silkworms spin cocoons naturally on twigs or substrates |

| Cocoon Shape | Uniform, compact on frames | Irregular, variable on natural surfaces |

| Silk Quality | Higher tensile strength, consistent fiber length | Variable quality, often shorter fiber length |

| Labor Intensity | Moderate manual handling required | Low manual intervention, mostly natural |

| Production Control | Better control over environment and cocoon quality | Limited control, depends on natural conditions |

| Harvesting Ease | Easy detachment from frames | More challenging due to natural substrates |

| Suitability | Ideal for commercial sericulture and large-scale production | Suitable for small-scale or traditional Sericulture |

Introduction to Cocoon Formation in Sericulture

Cocoon formation in sericulture involves two critical stages: mounting and spinning. During the mounting phase, silkworm larvae attach themselves to a suitable support structure, initiating the spinning process by secreting fibroin protein through their silk glands. The spinning stage follows as larvae continuously extrude silk fibers, creating the cocoon that serves as protective casing for pupation and silk harvesting.

Understanding Mounting and Spinning Processes

Mounting involves placing mature silkworm larvae onto frames or trays to initiate cocoon formation under controlled environmental conditions, ensuring optimal temperature and humidity for effective silk fiber production. Spinning refers to the natural behavior of the larvae as they secrete fibroin and sericin proteins to create the cocoon's protective silk threads around themselves. Understanding these processes is essential for maximizing cocoon quality and silk yield in sericulture operations.

The Role of Mounting in Cocoon Development

Mounting plays a crucial role in cocoon development by providing a stable surface for silkworms to anchor their silk fibers during the early stages of spinning. Proper mounting ensures optimal fiber alignment and cocoon uniformity, directly influencing silk quality and yield. In contrast, spinning primarily refers to the actual production of silk fibers, which depends heavily on the initial conditions established during mounting.

Spinning Behavior of Silkworms: An Overview

Spinning behavior in silkworms involves the secretion of fibroin and sericin proteins from their silk glands to form protective cocoons. During spinning, silkworms exhibit specific movements and patterns that influence cocoon shape, density, and quality, critical parameters for sericulture productivity. Understanding this behavior enables optimization of environmental factors to enhance silk yield and cocoon integrity.

Key Differences between Mounting and Spinning

Mounting involves placing silkworm larvae onto specially designed frames or trays to encourage cocoon formation in controlled environments, optimizing cocoon quality and uniformity. Spinning refers to the natural behavior where silkworms produce silk fibers by excreting fibroin through their spinnerets, forming cocoons independently without external guidance. The key difference lies in mounting as a human-managed process enhancing cocoon yield, while spinning is the innate biological activity of silk production by the larvae.

Importance of Mounting Techniques in Sericulture

Effective mounting techniques in sericulture play a crucial role in optimizing cocoon formation, directly impacting silk yield and quality. Proper mounting ensures uniform cocoon structure by providing ideal support and environmental conditions for silkworms during the spinning process. Enhanced mounting methods reduce cocoon damage and increase filament length, significantly improving raw silk extraction efficiency.

Factors Affecting Spinning Quality in Silkworms

Factors affecting spinning quality in silkworms include temperature, humidity, and nutrition, which directly influence the cocoon's density and silk filament length. Genetic variations among silkworm races also play a critical role in determining the strength and uniformity of the spun silk. Proper environmental control during mounting enhances fiber alignment and cocoon integrity, optimizing silk production efficiency.

Best Practices for Mounting and Spinning

Best practices for mounting in sericulture involve using clean, dry trays with proper ventilation to ensure uniform cocoon formation and prevent fungal contamination. For spinning, selecting high-quality silkworm breeds and maintaining optimal temperature and humidity levels around 25-28degC and 70-85% respectively enhances thread strength and productivity. Consistent monitoring during both mounting and spinning phases reduces wastage and improves overall silk yield.

Impact on Cocoon Yield and Quality

Mounting and spinning processes critically influence cocoon yield and quality in sericulture, with mounting typically resulting in higher cocoon uniformity and better silk filament length due to controlled environmental conditions and precise larval placement. Spinning allows larvae to select their own sites for cocoon formation, often leading to variability in cocoon size and shell weight, which can reduce overall silk yield and affect reeling efficiency. Studies indicate mounting enhances cocoon shell ratio and filament strength, thereby improving the economic value of the silk produced.

Conclusion: Optimizing Cocoon Formation in Sericulture

Optimizing cocoon formation in sericulture requires balancing mounting and spinning techniques to maximize silk yield and quality. Controlled mounting ensures proper alignment of silkworms, while efficient spinning facilitates uniform cocoon development with strong filament continuity. Integrating precise environmental conditions with these methods enhances fiber strength and overall productivity in sericulture operations.

Related Important Terms

Automated Mountage Systems

Automated mountage systems revolutionize cocoon formation by precisely positioning silkworms for optimal spinning, enhancing silk quality and yield. By automating the mounting process, these systems reduce labor costs and improve consistency in cocoon shape and density, critical factors for high-grade silk production in sericulture.

Vertical Spinning Frames

Vertical spinning frames in sericulture enhance cocoon formation by providing optimal spatial orientation for silkworms to mount and spin their cocoons efficiently. This method improves cocoon quality and uniformity, leading to higher silk yield compared to traditional mounting techniques.

Eco-Friendly Spinning Racks

Eco-friendly spinning racks offer a sustainable alternative to traditional mounting methods in sericulture by reducing material waste and energy consumption during cocoon formation. These racks enhance airflow and natural drying, promoting healthier silk fibers and minimizing the environmental impact associated with synthetic or metal spinning equipment.

Precision Mounting Devices

Precision mounting devices enhance the efficiency of sericulture by ensuring uniform cocoon formation through accurate placement of silkworms on mounting frames. These devices reduce larval injury and improve silk quality, leading to higher yield and consistency in commercial silk production.

Smart Cocoon Collector

Mounting involves placing silkworms on mulberry leaves to initiate cocoon formation, while spinning refers to the natural secretion and weaving of silk fibers by the larvae into cocoons. The Smart Cocoon Collector optimizes this process by automating cocoon harvesting, enhancing efficiency and reducing manual labor in sericulture farms.

Hygrothermal Spinning Units

Hygrothermal spinning units optimize cocoon formation by precisely controlling temperature and humidity to enhance silk filament quality during the mounting process. Maintaining optimal hygrothermal conditions in spinning units minimizes filament breakage and improves overall silk yield compared to conventional spinning methods.

Artificial Mountage Substrates

Artificial mountage substrates in sericulture provide uniform support for silkworms during cocoon formation, enhancing cocoon quality and silk yield compared to natural mounting surfaces. These substrates optimize spinning efficiency by facilitating stable attachment points, which reduce larval stress and promote consistent cocoon morphology.

Stress-Free Spinning Technology

Stress-free spinning technology enhances cocoon quality by allowing silkworms to spin naturally without physical constraints, reducing stress-induced defects during cocoon formation. This advanced method contrasts with mounting techniques that may cause stress, ensuring higher silk filament integrity and improved yield in sericulture production.

Microclimate-Controlled Mountage

Microclimate-controlled mountage enhances cocoon formation by precisely regulating temperature, humidity, and airflow, creating optimal conditions that improve silk quality and reduce pupal mortality. Compared to traditional spinning methods, this approach ensures uniform cocoon shape and density, boosting overall sericulture productivity.

AI-Assisted Spinning Monitoring

AI-assisted spinning monitoring enhances cocoon formation by precisely tracking silkworm movement and silk thread extrusion, optimizing conditions for superior cocoon quality. This technology reduces manual errors inherent in traditional mounting, improving silk yield and consistency in sericulture operations.

Mounting vs Spinning for Cocoon Formation Infographic

agridif.com

agridif.com