Disease-Free Layings (DFLs) ensure higher quality silkworm seed production compared to traditional seed cocoons by offering genetically pure and healthy larvae free from infections. Using DFLs reduces the risk of disease outbreaks and improves overall cocoon yield and silk quality in sericulture. Seed cocoons, while commonly used, often carry pathogens that can compromise silkworm health and productivity.

Table of Comparison

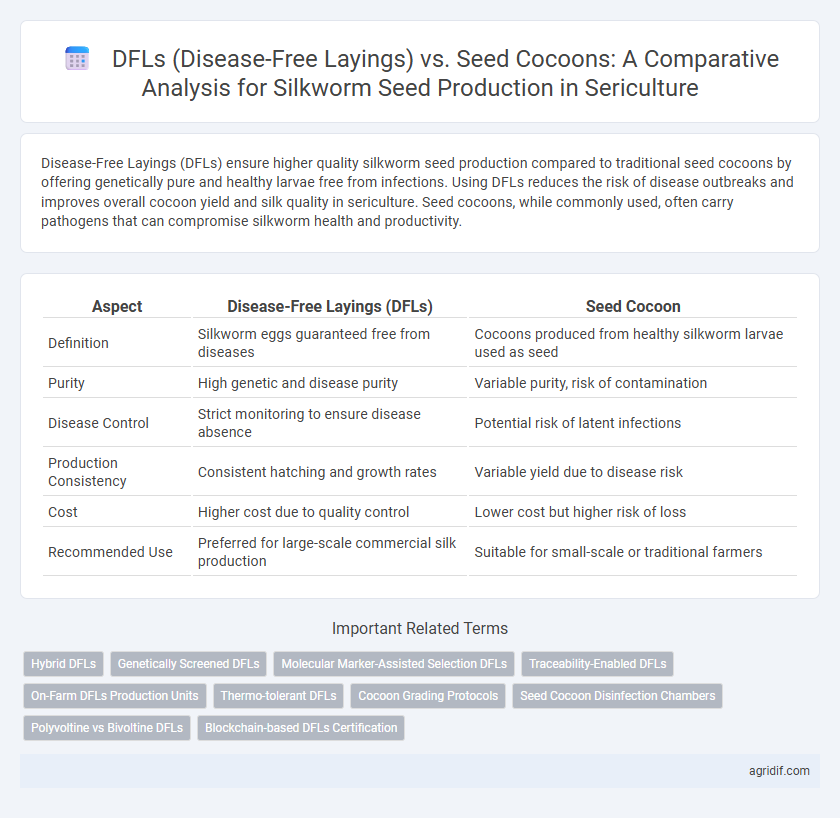

| Aspect | Disease-Free Layings (DFLs) | Seed Cocoon |

|---|---|---|

| Definition | Silkworm eggs guaranteed free from diseases | Cocoons produced from healthy silkworm larvae used as seed |

| Purity | High genetic and disease purity | Variable purity, risk of contamination |

| Disease Control | Strict monitoring to ensure disease absence | Potential risk of latent infections |

| Production Consistency | Consistent hatching and growth rates | Variable yield due to disease risk |

| Cost | Higher cost due to quality control | Lower cost but higher risk of loss |

| Recommended Use | Preferred for large-scale commercial silk production | Suitable for small-scale or traditional farmers |

Introduction to Silkworm Seed Production

Silkworm seed production relies heavily on the use of Disease-Free Layings (DFLs) to ensure high-quality silkworm eggs that promote healthy cocoon yield and reduce disease transmission risk. DFLs are produced through rigorous disease screening and controlled breeding, offering a reliable foundation compared to traditional seed cocoons, which may carry pathogens or show genetic variability. Utilizing certified DFLs enhances silkworm seed production efficiency by guaranteeing uniform larval growth and boosting overall sericulture productivity.

Understanding DFLs (Disease-Free Layings)

Disease-Free Layings (DFLs) represent a critical quality standard in sericulture, providing silkworm eggs guaranteed to be free from viral and bacterial infections that can devastate silk production. DFLs ensure higher hatchability rates and more uniform larval growth compared to traditional seed cocoons, which may carry latent diseases affecting the overall yield and silk quality. Utilizing DFLs in silkworm seed production enhances biosecurity, stabilizes sericulture output, and supports sustainable silk industry practices.

Overview of Seed Cocoon Method

The seed cocoon method in sericulture involves selecting high-quality, disease-resistant cocoons to produce silkworm seeds, ensuring genetic purity and vigor. This traditional approach relies on natural selection and environmental adaptation but carries higher risks of disease transmission compared to Disease-Free Layings (DFLs). Seed cocoons provide a cost-effective option for farmers, though they require meticulous handling to minimize contamination and maintain silk yield quality.

DFLs vs Seed Cocoon: Key Differences

Disease-Free Layings (DFLs) are predetermined batches of silkworm eggs guaranteed free from pathogens, ensuring uniformity and high hatchability, while Seed Cocoons are the actual cocoons spun by healthy silkworms used as breeding stock for producing these eggs. DFLs provide controlled disease management and ease of transportation, enabling consistent silk yield, whereas Seed Cocoons require careful maintenance of parent stock and entail risks of disease transmission. The use of DFLs reduces disease outbreaks during sericulture, optimizing quality and quantity of silk production compared to reliance solely on Seed Cocoons.

Quality Control in DFLs and Seed Cocoon Production

Disease-Free Layings (DFLs) undergo stringent quality control measures including rigorous screening for viral, bacterial, and fungal pathogens to ensure purity and high viability, directly impacting silkworm seed production success. Seed cocoon production also involves quality checks for cocoon firmness, shell ratio, and weight, but the initial pathogen-free guarantee in DFLs significantly reduces disease incidence and improves yield consistency. Effective quality control in DFL production enhances silkworm health and productivity more reliably than seed cocoon-based methods, establishing DFLs as the preferred standard for commercial sericulture operations.

Advantages of DFLs in Silkworm Seed Industry

Disease-Free Layings (DFLs) offer superior genetic purity and enhanced disease resistance compared to traditional seed cocoons, significantly boosting the survival and productivity of silkworms. The use of DFLs ensures uniform growth rates and high hatching percentages, contributing to consistent silk yield and quality. By minimizing the risk of pathogen transmission, DFLs reduce the need for chemical interventions, promoting sustainable and cost-effective silk production.

Challenges Faced in Seed Cocoon Utilization

Seed cocoons for silkworm seed production often present challenges such as higher susceptibility to diseases and variable viability, which can compromise the quality and consistency of silkworm larvae. In contrast, Disease-Free Layings (DFLs) offer uniformity and guaranteed health status, reducing the risks associated with pathogenic infections and improving crop yield stability. Managing environmental factors and ensuring rigorous quality control during seed cocoon handling remain critical obstacles limiting their widespread adoption.

Disease Management in DFLs and Seed Cocoons

Disease-Free Layings (DFLs) are critical for effective disease management in silkworm seed production, as they are produced under controlled conditions to minimize infection risks like grasserie and flacherie. Seed cocoons, while a traditional source, are more vulnerable to pathogen transmission due to environmental exposure during field rearing. Implementing strict hygiene protocols and regular monitoring in DFL production ensures healthier silkworm stock, significantly reducing the incidence of silkworm diseases compared to seed cocoon-based multiplication.

Modern Trends in Silkworm Seed Production

Disease-Free Layings (DFLs) have revolutionized silkworm seed production by ensuring higher purity and uniformity compared to traditional seed cocoon methods, reducing disease incidence and enhancing crop yield. Modern trends emphasize laboratory-based production of DFLs under controlled aseptic conditions to maximize genetic potential and sustainability. Integration of molecular diagnostics and biotechnological tools further refines the quality and scalability of DFLs, marking a significant shift from conventional seed cocoon practices.

Future Prospects: DFLs or Seed Cocoon?

Disease-Free Layings (DFLs) offer a standardized and controlled approach to silkworm seed production, enhancing genetic purity and disease resistance compared to traditional seed cocoons. The future of sericulture leans towards DFLs due to their scalability, consistent quality, and the ability to integrate molecular breeding techniques for improved silkworm strains. Seed cocoons may still hold regional importance, but advancements in biotechnology and quality control position DFLs as the dominant method for sustainable and efficient silkworm seed production.

Related Important Terms

Hybrid DFLs

Hybrid DFLs (Disease-Free Layings) offer superior genetic traits and higher hatchability rates compared to traditional seed cocoons, resulting in enhanced silkworm seed production efficiency. Utilizing Hybrid DFLs in sericulture significantly reduces disease incidence and improves larval vigor, promoting sustainable silk yield and quality throughout the rearing process.

Genetically Screened DFLs

Genetically screened Disease-Free Layings (DFLs) provide superior silkworm seed quality by ensuring high genetic purity and resistance to common silkworm diseases, directly enhancing cocoon yield and filament quality. In contrast, traditional seed cocoons often carry microbial contaminants and genetic variability, leading to inconsistent seed production and increased vulnerability to infections in sericulture.

Molecular Marker-Assisted Selection DFLs

Molecular Marker-Assisted Selection (MAS) enhances the production of Disease-Free Layings (DFLs) by enabling precise identification of disease-resistant and high-yield silkworm strains, ensuring superior genetic purity compared to traditional Seed Cocoon methods. MAS-based DFLs improve silkworm seed quality, minimize viral and bacterial infections, and increase silk yield, making them pivotal for sustainable sericulture advancements.

Traceability-Enabled DFLs

Traceability-enabled Disease-Free Layings (DFLs) offer precise monitoring of genetic lineage and health status, ensuring higher quality silkworm seed production compared to traditional seed cocoons. This technology enhances disease control and productivity by allowing detailed tracking of silkworm batches from origin to rearing stages.

On-Farm DFLs Production Units

On-farm Disease-Free Layings (DFLs) production units ensure enhanced control over silkworm seed quality by minimizing the risk of infections compared to traditional seed cocoon methods, promoting higher hatchability and larval vigor. Integrating DFL technology within sericulture farms supports sustainable silk production through localized disease management and consistent supply of pathogen-free silkworm seeds.

Thermo-tolerant DFLs

Thermo-tolerant Disease-Free Layings (DFLs) offer enhanced resilience against high temperatures, ensuring consistent silkworm seed production under climate stress compared to traditional seed cocoons. Utilizing thermo-tolerant DFLs significantly reduces mortality rates and improves larval vigor, leading to higher yield and quality in sericulture operations.

Cocoon Grading Protocols

Disease-Free Layings (DFLs) ensure higher genetic purity and vitality compared to seed cocoons, which are more susceptible to infections and genetic variations. Cocoon grading protocols emphasize parameters like cocoon weight, shell ratio, and pupal health to differentiate quality seed cocoons, whereas DFLs rely on meticulous laboratory screening and disease-free assurance for optimal silkworm seed production.

Seed Cocoon Disinfection Chambers

Seed Cocoon Disinfection Chambers play a crucial role in eradicating pathogens from seed cocoons, ensuring higher purity and viability of silkworm seed production compared to Disease-Free Layings (DFLs). These chambers use controlled treatments like fumigation or heat to effectively eliminate microbial contaminants, improving silkworm health and increasing overall cocoon yield.

Polyvoltine vs Bivoltine DFLs

Polyvoltine DFLs offer higher adaptability and multiple life cycles annually, enhancing seed cocoon production efficiency in tropical climates, while Bivoltine DFLs yield superior silk quality with longer filaments but require controlled environments due to their sensitivity. Selecting between polyvoltine and bivoltine seed cocoon sources depends on balancing yield demands, silk quality, and regional climatic conditions for optimized silkworm seed production.

Blockchain-based DFLs Certification

Blockchain-based DFLs certification ensures transparent tracking and authenticity in the production of Disease-Free Layings, significantly reducing the risk of silkworm disease transmission compared to traditional seed cocoon methods. This technology enhances trust among sericulturists by providing immutable records of silk moth breeding processes, promoting sustainable and efficient silkworm seed production.

DFLs (Disease-Free Layings) vs Seed Cocoon for Silkworm Seed Production Infographic

agridif.com

agridif.com