Batch processing in juice production offers greater flexibility and control over small-scale batches, allowing precise adjustments in flavor and quality. Continuous processing enables higher throughput and consistent product quality by maintaining a steady flow through automated systems, ideal for large-scale production. Selecting the optimal method depends on production volume, cost efficiency, and desired end-product characteristics.

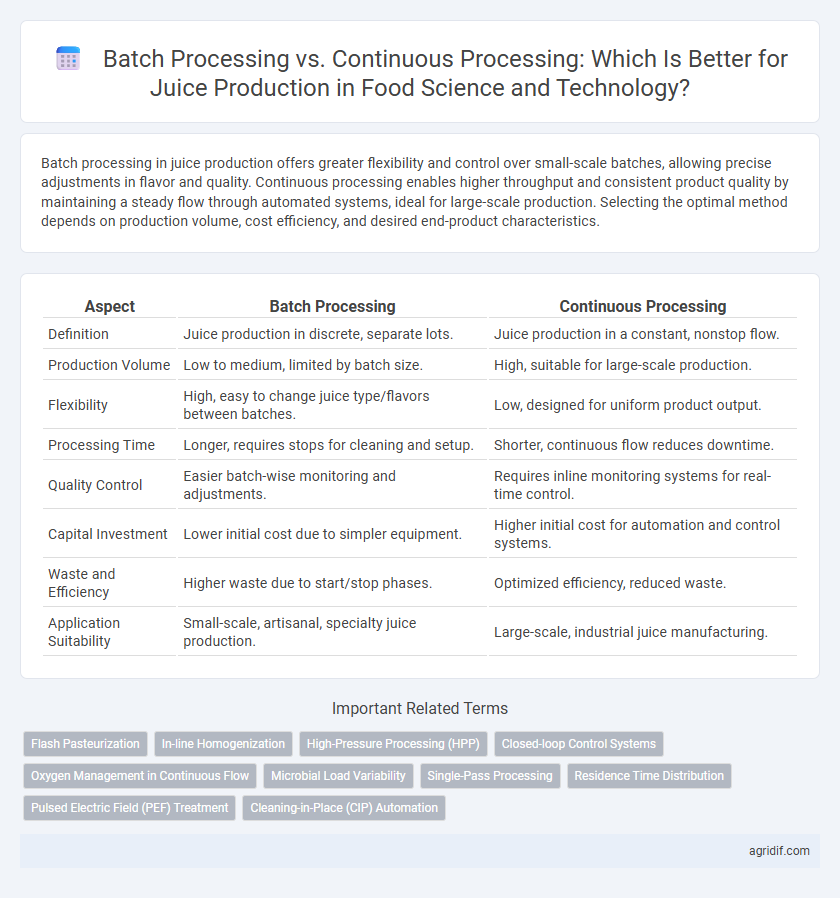

Table of Comparison

| Aspect | Batch Processing | Continuous Processing |

|---|---|---|

| Definition | Juice production in discrete, separate lots. | Juice production in a constant, nonstop flow. |

| Production Volume | Low to medium, limited by batch size. | High, suitable for large-scale production. |

| Flexibility | High, easy to change juice type/flavors between batches. | Low, designed for uniform product output. |

| Processing Time | Longer, requires stops for cleaning and setup. | Shorter, continuous flow reduces downtime. |

| Quality Control | Easier batch-wise monitoring and adjustments. | Requires inline monitoring systems for real-time control. |

| Capital Investment | Lower initial cost due to simpler equipment. | Higher initial cost for automation and control systems. |

| Waste and Efficiency | Higher waste due to start/stop phases. | Optimized efficiency, reduced waste. |

| Application Suitability | Small-scale, artisanal, specialty juice production. | Large-scale, industrial juice manufacturing. |

Overview of Batch and Continuous Processing in Juice Production

Batch processing in juice production involves processing fixed quantities of fruit in discrete steps, allowing for precise control over quality and customization but resulting in lower throughput and higher labor costs. Continuous processing, by contrast, enables an uninterrupted flow of juice extraction and pasteurization, maximizing output and efficiency while demanding advanced automation and consistent raw material quality. Selecting between batch and continuous processing depends on production scale, desired product consistency, and investment in technology infrastructure.

Key Differences Between Batch and Continuous Juice Processing

Batch processing in juice production involves processing fixed quantities of raw materials in discrete steps, enabling precise control over quality and ingredient customization but often resulting in longer production times and higher labor costs. Continuous processing operates by feeding raw materials into the system without interruption, maximizing throughput and efficiency while maintaining consistent product quality due to steady-state conditions. Key differences include batch processing's flexibility and suitability for small-scale or specialty juice products versus continuous processing's advantage in large-scale, high-volume juice manufacturing with reduced contamination risk and operational downtime.

Equipment and Technology Used in Each Processing Method

Batch processing in juice production typically utilizes equipment such as large tanks, mixers, and batch pasteurizers that allow for controlled, intermittent handling of raw materials and juices, providing flexibility for small to medium-scale operations. Continuous processing employs advanced technologies like inline homogenizers, continuous pasteurizers, and automated separators, enabling a seamless flow of juice through extraction, clarification, and pasteurization stages, optimizing efficiency for large-scale production. Integration of sensors and automation in continuous systems enhances monitoring and control, reducing downtime and improving product consistency compared to the manual intervention required in batch processing equipment.

Impact on Juice Quality and Nutritional Value

Batch processing in juice production allows for precise control over processing parameters, often preserving delicate flavors and nutrients such as vitamin C and antioxidants more effectively. Continuous processing offers higher efficiency and consistent quality but may subject juice to prolonged heat exposure, potentially reducing nutritional value and altering sensory attributes. Optimizing temperature and processing time in either method is crucial to maintaining juice quality and maximizing retention of essential nutrients.

Efficiency and Production Capacity Considerations

Batch processing in juice production allows for flexible recipe adjustments and quality control but typically results in lower efficiency and limited production capacity due to downtime between batches. Continuous processing enhances efficiency by enabling nonstop juice extraction and pasteurization, significantly increasing throughput while reducing labor costs. Factories aiming for high-volume juice output often prefer continuous processing to meet large-scale demand and optimize resource utilization.

Cost Analysis: Batch vs Continuous Juice Processing

Batch processing in juice production typically involves higher labor and downtime costs due to intermittent operation and frequent cleaning cycles, making it less cost-efficient for large-scale production. Continuous processing benefits from economies of scale, reduced labor requirements, and consistent throughput, significantly lowering per-unit costs in high-volume juice manufacturing. Capital investment for continuous systems is higher, but operational savings and increased productivity often result in better overall cost efficiency over time.

Scalability and Flexibility for Different Juice Products

Batch processing in juice production offers high flexibility, allowing manufacturers to easily switch between different fruit varieties and custom formulations, ideal for limited-scale operations. Continuous processing excels in scalability with its ability to handle large volumes efficiently, supporting consistent quality for mass production of standardized juice products. Choosing between the two depends on the desired production scale and product diversity, with batch processing favored for variety and continuous processing for volume.

Hygiene, Safety, and Contamination Risks

Batch processing in juice production allows for controlled hygiene protocols and easier identification of contamination sources, reducing food safety risks. Continuous processing offers higher efficiency but demands rigorous, automated sanitation systems to prevent microbial growth and cross-contamination. Advanced monitoring technologies and sanitary design in continuous systems mitigate contamination risks while maintaining product safety and quality.

Sustainability and Environmental Impact

Batch processing in juice production typically results in higher energy consumption and increased water usage per unit, contributing to a larger environmental footprint compared to continuous processing. Continuous processing systems optimize resource efficiency by minimizing waste generation, reducing water and energy consumption through streamlined operations. Implementing continuous processing technology enhances sustainability by lowering greenhouse gas emissions and enabling better integration with renewable energy sources in juice manufacturing.

Choosing the Right Processing Method for Your Juice Business

Batch processing offers flexibility and precise control, ideal for small-scale juice businesses requiring varied flavors and seasonal products. Continuous processing maximizes efficiency and consistency, suitable for large-scale production with high demand and uniform quality standards. Evaluating production volume, product diversity, and investment capacity helps determine the optimal method for juice manufacturing operations.

Related Important Terms

Flash Pasteurization

Flash pasteurization in juice production is more efficiently integrated into continuous processing systems, allowing rapid heating and cooling that preserves nutrient content and flavor while ensuring microbial safety. Batch processing involves slower, intermittent heating phases that can degrade juice quality and reduce throughput compared to the precise temperature control and high productivity of continuous flash pasteurization.

In-line Homogenization

In juice production, batch processing allows for precise control over small volumes but often results in inconsistent product quality and longer processing times. Continuous processing with in-line homogenization ensures uniform particle size reduction, improving juice stability and quality while increasing throughput and operational efficiency.

High-Pressure Processing (HPP)

Batch processing in juice production using High-Pressure Processing (HPP) ensures uniform microbial inactivation and retention of nutrients with precise control over pressure and holding time, making it ideal for small-scale or premium products. Continuous processing, integrated with HPP systems, enhances throughput and operational efficiency by applying constant high pressure to juice flows, suitable for large-scale commercial production while maintaining product quality and safety.

Closed-loop Control Systems

Closed-loop control systems enhance juice production by maintaining precise temperature, pH, and flow rates, optimizing both batch and continuous processing methods. Continuous processing benefits from real-time feedback loops ensuring consistent product quality, while batch processing leverages closed-loop controls for accurate stage monitoring and repeatability.

Oxygen Management in Continuous Flow

Continuous processing in juice production incorporates advanced oxygen management systems that minimize oxidation and preserve nutrient integrity by maintaining low dissolved oxygen levels throughout the flow path. This approach contrasts with batch processing, where oxygen exposure is less controlled, leading to higher risks of enzymatic browning and quality degradation.

Microbial Load Variability

Batch processing in juice production often results in higher microbial load variability due to intermittent processing and repeated exposure to contamination sources, whereas continuous processing maintains more consistent microbial control by providing steady-state conditions and reducing microbial proliferation risks. Continuous processing systems enhance food safety by minimizing cross-contamination and ensuring uniform thermal treatment, leading to reduced microbial load fluctuations compared to batch methods.

Single-Pass Processing

Single-pass processing in juice production offers enhanced efficiency by allowing continuous extraction and pasteurization within a streamlined operation, reducing product handling and contamination risks. This approach contrasts with batch processing by providing consistent quality and higher throughput, making it ideal for large-scale fruit juice manufacturing.

Residence Time Distribution

Batch processing in juice production features a broad residence time distribution (RTD), leading to variable product quality and potential overprocessing or underprocessing of some juice portions. Continuous processing offers a narrower RTD, ensuring uniform thermal exposure, consistent quality, and enhanced efficiency in microbial inactivation and nutrient retention.

Pulsed Electric Field (PEF) Treatment

Batch processing in juice production allows precise control over Pulsed Electric Field (PEF) treatment parameters, enhancing microbial inactivation and preserving nutritional quality, but it limits scalability and throughput. Continuous processing integrates PEF treatment into high-volume lines, improving efficiency and consistent product quality while requiring advanced system design to manage energy input and treatment uniformity.

Cleaning-in-Place (CIP) Automation

Batch processing in juice production requires periodic manual Cleaning-in-Place (CIP), which can lead to extended downtime and inconsistent sanitation results. Continuous processing leverages automated CIP systems that ensure consistent cleanliness, reduce processing interruptions, and optimize hygiene efficiency in high-volume production environments.

Batch processing vs continuous processing for juice production Infographic

agridif.com

agridif.com