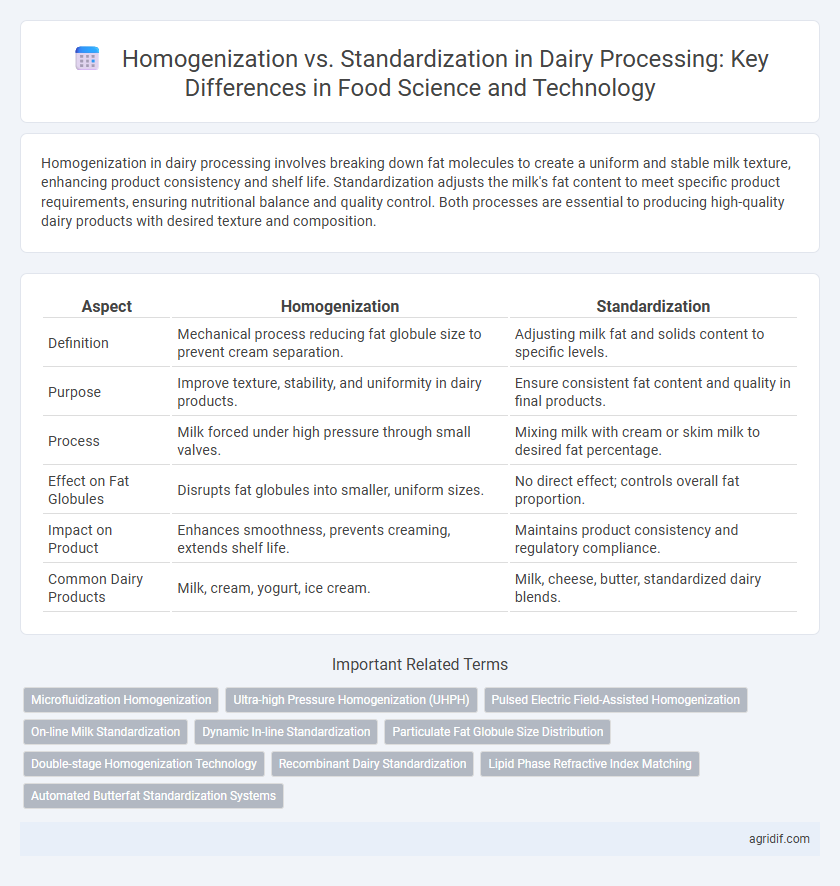

Homogenization in dairy processing involves breaking down fat molecules to create a uniform and stable milk texture, enhancing product consistency and shelf life. Standardization adjusts the milk's fat content to meet specific product requirements, ensuring nutritional balance and quality control. Both processes are essential to producing high-quality dairy products with desired texture and composition.

Table of Comparison

| Aspect | Homogenization | Standardization |

|---|---|---|

| Definition | Mechanical process reducing fat globule size to prevent cream separation. | Adjusting milk fat and solids content to specific levels. |

| Purpose | Improve texture, stability, and uniformity in dairy products. | Ensure consistent fat content and quality in final products. |

| Process | Milk forced under high pressure through small valves. | Mixing milk with cream or skim milk to desired fat percentage. |

| Effect on Fat Globules | Disrupts fat globules into smaller, uniform sizes. | No direct effect; controls overall fat proportion. |

| Impact on Product | Enhances smoothness, prevents creaming, extends shelf life. | Maintains product consistency and regulatory compliance. |

| Common Dairy Products | Milk, cream, yogurt, ice cream. | Milk, cheese, butter, standardized dairy blends. |

Introduction to Dairy Processing: Homogenization and Standardization

Homogenization in dairy processing involves mechanically breaking down fat globules to create a uniform milk texture, preventing cream separation and enhancing sensory qualities. Standardization adjusts the fat content to a desired level by blending milk with cream or skim milk, ensuring product consistency and regulatory compliance. Both processes are critical for producing high-quality dairy products with stable texture and standardized nutritional profiles.

Defining Homogenization in Dairy Technology

Homogenization in dairy technology refers to the mechanical process that breaks down fat globules in milk into smaller, uniformly distributed particles to prevent cream separation. This technique enhances the milk's texture, stability, and digestibility by creating a stable emulsion between fat and liquid components. Unlike standardization, which adjusts fat content to achieve consistency, homogenization improves the structural quality and sensory attributes of dairy products.

The Process and Purpose of Standardization in Milk

Standardization in milk involves adjusting fat content to a specific level, ensuring consistent quality and nutritional value across dairy products. This process typically utilizes separation and recombination techniques to achieve uniform fat distribution before further processing. Standardization enhances product stability, optimizes yield, and aligns milk composition with regulatory and consumer standards.

Key Differences Between Homogenization and Standardization

Homogenization in dairy processing involves mechanically breaking down fat globules to achieve a uniform milk consistency, preventing cream separation, whereas standardization adjusts the milk's fat content to a specific level for product consistency and quality control. Homogenization targets physical milk structure, improving texture and stability, while standardization ensures nutritional and compositional uniformity essential for regulatory compliance. These processes operate at different stages, with standardization primarily altering fat concentrations before homogenization refines the final product's physical properties.

Impact of Homogenization on Milk Quality and Texture

Homogenization significantly enhances milk quality by reducing fat globule size, ensuring uniform fat distribution and preventing cream separation. This process improves texture, resulting in a smoother, creamier mouthfeel and consistent viscosity. Homogenization also increases milk's digestibility and shelf life by inhibiting lipase activity and microbial growth.

Effects of Standardization on Dairy Product Consistency

Standardization in dairy processing ensures uniform fat content, directly influencing the texture and mouthfeel of dairy products. By adjusting the composition of milk, standardization promotes consistent viscosity and stability, essential for achieving reliable product quality in items like yogurt and cheese. This controlled balance reduces variability, enhancing consumer satisfaction and streamlining production efficiency.

Technological Innovations in Homogenization and Standardization

Technological innovations in homogenization have advanced with high-pressure homogenizers and ultrasonic techniques, enhancing fat globule size reduction and improving milk stability and texture. In standardization, precision milk analyzers and automated blending systems enable accurate adjustment of fat and solids content, ensuring consistent product quality. These innovations drive efficiency and product uniformity in dairy processing, meeting stringent industry standards.

Quality Control Measures in Dairy Processing

Homogenization in dairy processing breaks down fat globules to create a uniform milk texture, improving mouthfeel and preventing cream separation, while standardization adjusts fat content to meet product specifications, ensuring consistency and regulatory compliance. Quality control measures include monitoring particle size distribution via laser diffraction for homogenization efficacy and using infrared spectroscopy to verify fat percentages during standardization. Regular calibration of equipment and sensory evaluation underpin these processes, maintaining product stability and consumer satisfaction in dairy production.

Consumer Perspectives: Homogenized vs Standardized Dairy Products

Consumer preferences for homogenized dairy products often stem from the smoother texture and consistent taste achieved through the reduction of fat globule size, which improves mouthfeel and shelf life. Standardized dairy products appeal to those seeking nutritional control, as fat content is precisely adjusted to meet dietary needs or regulatory standards. Both processes influence perceived quality and acceptance, with homogenization enhancing sensory appeal and standardization ensuring health-conscious consumption.

Future Trends in Dairy Processing: Integrating Homogenization and Standardization

Future trends in dairy processing emphasize the integration of homogenization and standardization techniques to enhance product consistency and nutritional quality. Advanced homogenization methods improve fat globule dispersion, while precise standardization ensures uniform fat content across batches, optimizing sensory attributes and shelf life. Emerging technologies like ultrasonic homogenization and inline standardization systems are driving efficiencies and sustainability in large-scale dairy production.

Related Important Terms

Microfluidization Homogenization

Microfluidization homogenization in dairy processing uses high-pressure jet streams to reduce fat globule size, enhancing texture, stability, and shelf life compared to traditional homogenization. This precise technology improves creaminess and uniformity in dairy products by optimizing particle size distribution and promoting better protein-fat interactions.

Ultra-high Pressure Homogenization (UHPH)

Ultra-high Pressure Homogenization (UHPH) enhances dairy processing by applying pressures above 200 MPa, significantly reducing fat globule size and improving product stability and shelf life compared to traditional homogenization. Unlike standardization, which adjusts milk composition by fat separation, UHPH physically modifies milk structure at the molecular level, leading to superior texture and microbial safety without altering nutrient profiles.

Pulsed Electric Field-Assisted Homogenization

Pulsed Electric Field-Assisted Homogenization enhances dairy processing by improving fat globule size reduction and distribution compared to conventional homogenization, leading to better texture and stability in milk and cream products. This technology also offers energy efficiency and preserves nutritional quality, distinguishing it from standardization practices that primarily adjust milk composition without altering physical properties.

On-line Milk Standardization

On-line milk standardization in dairy processing precisely adjusts fat and solids content before homogenization to ensure consistent product quality and optimize yield. This real-time control enhances process efficiency by maintaining target composition, reducing raw milk variability, and improving downstream homogenization performance.

Dynamic In-line Standardization

Dynamic in-line standardization in dairy processing allows precise adjustment of milk fat content by blending skimmed and cream streams before homogenization, enhancing product consistency and process efficiency. This method contrasts with homogenization, which primarily reduces fat globule size to improve texture and stability without altering fat concentration.

Particulate Fat Globule Size Distribution

Homogenization reduces the average size of fat globules in milk from about 3-10 micrometers to less than 1 micrometer, resulting in a uniform particulate fat globule size distribution that enhances product stability and texture. Standardization adjusts the total fat content without altering the size distribution of fat globules, maintaining the original particulate profile but ensuring consistent nutritional composition in dairy products.

Double-stage Homogenization Technology

Double-stage homogenization technology enhances dairy processing by using two successive pressure stages to break down fat globules, improving milk texture and stability more effectively than single-stage methods. Compared to standardization, which adjusts fat content, double-stage homogenization optimizes emulsion quality and shelf life by producing uniformly sized fat particles and preventing cream separation.

Recombinant Dairy Standardization

Recombinant dairy standardization in dairy processing involves precisely adjusting milk components using genetically engineered enzymes to achieve consistent fat and protein levels, enhancing product uniformity and nutritional value. Unlike homogenization, which mechanically breaks fat globules to improve texture and stability, recombinant standardization targets molecular composition for optimized dairy formulations and functional properties.

Lipid Phase Refractive Index Matching

Homogenization in dairy processing reduces fat globule size to improve stability, while standardization adjusts fat content to meet product specifications; lipid phase refractive index matching is critical for ensuring optical uniformity and preventing light scattering in homogenized dairy products. Precise control of refractive indices between the lipid and aqueous phases enhances product appearance and texture by minimizing turbidity and cream separation.

Automated Butterfat Standardization Systems

Automated butterfat standardization systems in dairy processing enhance product consistency by precisely adjusting fat content during production, improving quality control compared to traditional homogenization methods that mainly target fat globule size reduction. These systems leverage real-time fat measurement and computerized blending, enabling optimized milk standardization for diverse dairy products and maximizing process efficiency.

Homogenization vs Standardization for Dairy Processing Infographic

agridif.com

agridif.com