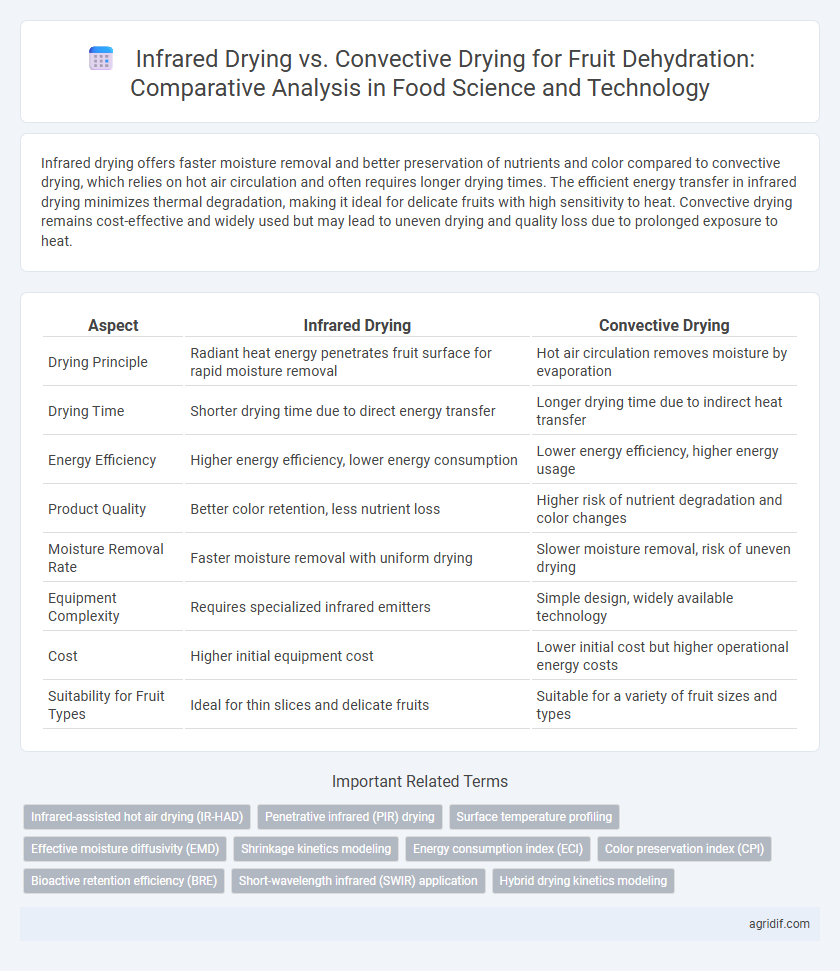

Infrared drying offers faster moisture removal and better preservation of nutrients and color compared to convective drying, which relies on hot air circulation and often requires longer drying times. The efficient energy transfer in infrared drying minimizes thermal degradation, making it ideal for delicate fruits with high sensitivity to heat. Convective drying remains cost-effective and widely used but may lead to uneven drying and quality loss due to prolonged exposure to heat.

Table of Comparison

| Aspect | Infrared Drying | Convective Drying |

|---|---|---|

| Drying Principle | Radiant heat energy penetrates fruit surface for rapid moisture removal | Hot air circulation removes moisture by evaporation |

| Drying Time | Shorter drying time due to direct energy transfer | Longer drying time due to indirect heat transfer |

| Energy Efficiency | Higher energy efficiency, lower energy consumption | Lower energy efficiency, higher energy usage |

| Product Quality | Better color retention, less nutrient loss | Higher risk of nutrient degradation and color changes |

| Moisture Removal Rate | Faster moisture removal with uniform drying | Slower moisture removal, risk of uneven drying |

| Equipment Complexity | Requires specialized infrared emitters | Simple design, widely available technology |

| Cost | Higher initial equipment cost | Lower initial cost but higher operational energy costs |

| Suitability for Fruit Types | Ideal for thin slices and delicate fruits | Suitable for a variety of fruit sizes and types |

Introduction to Fruit Dehydration Methods

Infrared drying utilizes radiant heat to penetrate fruit tissues, enabling rapid moisture removal while preserving nutritional qualities and color. Convective drying relies on hot air circulation, often resulting in longer drying times and potential nutrient degradation due to prolonged heat exposure. Comparative studies show infrared drying enhances energy efficiency and product quality in fruit dehydration processes compared to traditional convective methods.

Principles of Infrared Drying in Food Processing

Infrared drying utilizes electromagnetic radiation to generate heat directly within fruit tissues by causing molecular vibration, leading to rapid moisture removal and reduced drying time compared to convective drying. This method enhances energy efficiency as infrared waves penetrate the fruit surface, minimizing heat loss to the surrounding air and preserving nutritional quality and color. Infrared drying also reduces oxidation and thermal degradation by concentrating heat application, making it a superior technique for dehydration in food processing.

Mechanism of Convective Drying for Fruits

Convective drying for fruit dehydration operates by circulating hot air around the fruit, facilitating moisture evaporation from the surface. Heat transfer occurs primarily through convection, where thermal energy penetrates the fruit's surface, raising internal temperature and accelerating water diffusion toward the outer layer. This mechanism ensures uniform drying by maintaining a consistent temperature gradient, thereby preserving fruit quality and minimizing nutrient loss.

Comparative Analysis: Infrared vs Convective Drying

Infrared drying enables faster moisture removal from fruits by directly heating surface water molecules, resulting in reduced drying time and better retention of nutritional quality compared to convective drying, which relies on hot air circulation and often causes higher nutrient loss. Energy efficiency of infrared drying surpasses convective methods due to lower thermal gradients and minimized heat loss. Studies indicate infrared drying produces fruits with superior texture and color preservation, making it a preferable technology for high-quality fruit dehydration.

Effects on Fruit Quality: Color, Flavor, and Texture

Infrared drying preserves fruit color more effectively by reducing enzymatic browning compared to convective drying, which often causes color fading due to prolonged exposure to hot air. The intense heat from infrared drying helps retain natural flavor compounds, resulting in a more vibrant and fresh-tasting product, whereas convective drying may lead to flavor loss through oxidation. Texture retention is superior with infrared drying as it induces rapid moisture removal, minimizing cell collapse and maintaining fruit firmness, while convective drying frequently results in a tougher, less desirable texture.

Nutrient Retention in Infrared and Convective Drying

Infrared drying preserves higher levels of vitamins and antioxidants in fruits compared to convective drying due to its rapid moisture removal and reduced exposure to high temperatures. Convective drying often results in greater nutrient degradation because of prolonged drying times and direct heat exposure, which accelerate the breakdown of heat-sensitive compounds. Studies indicate that infrared drying maintains up to 30% more vitamin C and phenolic content than traditional convective methods in fruit dehydration.

Energy Efficiency and Cost Implications

Infrared drying demonstrates higher energy efficiency compared to convective drying by directly heating fruit surfaces, reducing drying time and energy consumption by up to 40%. Convective drying, reliant on heated air circulation, incurs higher operational costs due to prolonged drying durations and greater thermal losses. The reduced energy demand and faster processing of infrared drying translate to significant cost savings in industrial fruit dehydration processes.

Process Time and Throughput

Infrared drying significantly reduces process time for fruit dehydration compared to convective drying by providing rapid and uniform heat transfer directly to the fruit surface, often cutting drying durations by up to 50%. The accelerated drying kinetics in infrared drying enhance throughput capacity, enabling higher batch volumes to be processed within the same timeframe. In contrast, convective drying relies on slower heat transfer through hot air circulation, leading to extended drying cycles and lower throughput efficiency.

Application Challenges and Limitations

Infrared drying offers rapid heat penetration for fruit dehydration but faces challenges in uniformity, often causing surface overheating and uneven moisture removal. Convective drying ensures gradual and even drying through hot air circulation, yet it demands longer processing times and higher energy consumption. Both methods encounter limitations in preserving fruit quality attributes like texture and nutrient retention, necessitating optimization for specific fruit types and drying parameters.

Future Trends in Fruit Drying Technology

Infrared drying offers faster moisture removal and higher energy efficiency compared to traditional convective drying, enabling better retention of fruit nutrients and color. Emerging hybrid technologies combining infrared with convective methods are expected to enhance drying uniformity and reduce processing times for fruit dehydration. Advances in sensor integration and AI-driven process control are projected to optimize drying parameters, improving product quality and sustainability in future fruit drying applications.

Related Important Terms

Infrared-assisted hot air drying (IR-HAD)

Infrared-assisted hot air drying (IR-HAD) enhances fruit dehydration by combining rapid heat transfer from infrared radiation with uniform moisture removal via convective airflow, resulting in shorter drying times and improved product quality compared to conventional convective drying alone. IR-HAD preserves sensory attributes and bioactive compounds such as vitamins and antioxidants more effectively due to reduced thermal degradation and oxidative damage during the dehydration process.

Penetrative infrared (PIR) drying

Penetrative infrared (PIR) drying significantly enhances fruit dehydration by ensuring uniform heat distribution and deeper energy penetration compared to conventional convective drying, which primarily relies on surface heat transfer and air circulation. PIR drying reduces drying time and energy consumption while preserving fruit quality factors such as color, texture, and nutrient content more effectively than convective methods.

Surface temperature profiling

Infrared drying achieves higher surface temperature profiles compared to convective drying, enabling faster moisture removal and better retention of fruit color and nutrients. Convective drying exhibits lower and more uniform surface temperatures, reducing thermal degradation but often resulting in longer drying times and potential quality loss.

Effective moisture diffusivity (EMD)

Infrared drying exhibits higher Effective Moisture Diffusivity (EMD) values compared to convective drying, facilitating faster internal moisture migration and reduced drying time in fruit dehydration. Enhanced EMD in infrared drying results from direct energy penetration and rapid heat transfer, improving drying efficiency and preserving fruit quality.

Shrinkage kinetics modeling

Infrared drying demonstrates faster moisture removal and reduced shrinkage in fruit dehydration compared to convective drying, attributed to its direct heat transfer mechanism. Modeling shrinkage kinetics using empirical and semi-theoretical equations reveals that infrared drying exhibits lower volumetric contraction rates, enhancing texture retention and drying efficiency.

Energy consumption index (ECI)

Infrared drying for fruit dehydration significantly reduces the Energy Consumption Index (ECI) compared to convective drying by delivering rapid surface heating and minimizing heat loss. This method improves energy efficiency, cutting drying time and lowering operational costs while preserving fruit quality.

Color preservation index (CPI)

Infrared drying demonstrates a higher Color Preservation Index (CPI) compared to convective drying due to its rapid heating and reduced exposure time, minimizing enzymatic browning and pigment degradation in fruits. Studies reveal that infrared drying can maintain up to 85-90% of the original fruit color, whereas convective drying typically retains only 60-70%, highlighting its superior efficiency in preserving visual quality during dehydration.

Bioactive retention efficiency (BRE)

Infrared drying exhibits higher Bioactive Retention Efficiency (BRE) compared to convective drying for fruit dehydration due to its rapid heat transfer and shorter drying times, which minimize the degradation of heat-sensitive bioactive compounds like phenolics and vitamins. Studies demonstrate that infrared drying preserves antioxidant capacity and nutrient content more effectively, enhancing the nutritional quality and functional properties of dried fruits.

Short-wavelength infrared (SWIR) application

Short-wavelength infrared (SWIR) drying significantly reduces drying time and energy consumption compared to conventional convective drying in fruit dehydration by enhancing moisture removal through direct radiation absorption. SWIR application improves product quality by minimizing thermal degradation and preserving nutritional content, making it a more efficient and effective method for industrial-scale fruit drying operations.

Hybrid drying kinetics modeling

Hybrid drying kinetics modeling combines infrared and convective drying methods to optimize fruit dehydration by enhancing heat and mass transfer rates, resulting in reduced drying time and improved product quality. Computational models integrating infrared radiation intensity and air velocity parameters predict moisture diffusion and shrinkage behavior, enabling precise control over drying processes for uniform and efficient dehydration.

Infrared drying vs convective drying for fruit dehydration Infographic

agridif.com

agridif.com