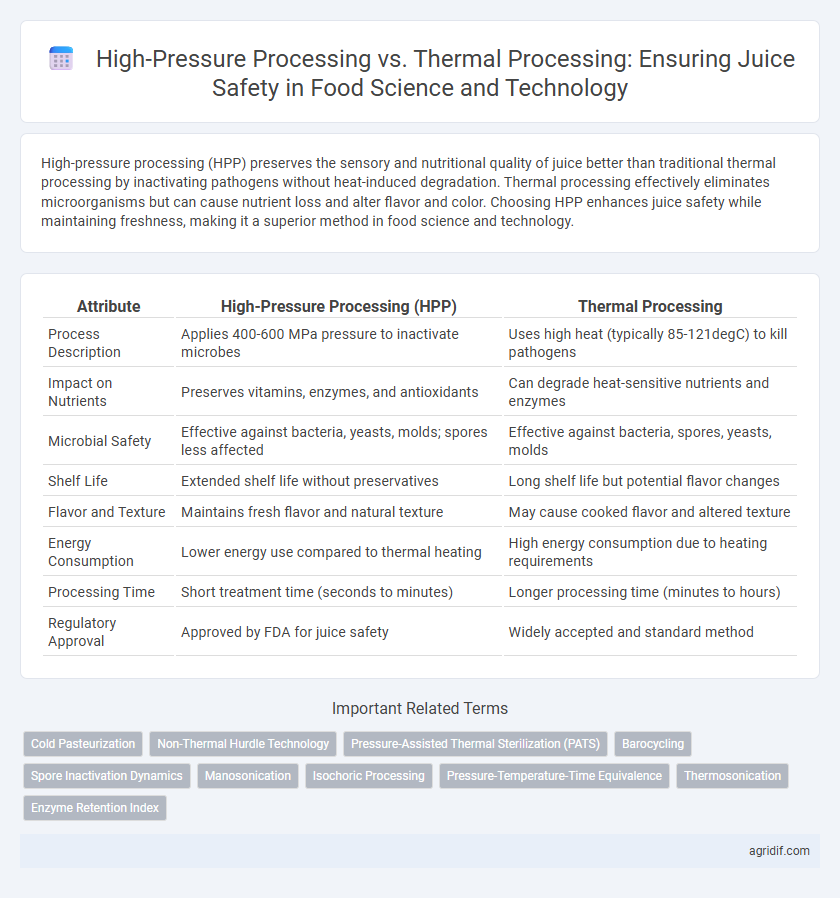

High-pressure processing (HPP) preserves the sensory and nutritional quality of juice better than traditional thermal processing by inactivating pathogens without heat-induced degradation. Thermal processing effectively eliminates microorganisms but can cause nutrient loss and alter flavor and color. Choosing HPP enhances juice safety while maintaining freshness, making it a superior method in food science and technology.

Table of Comparison

| Attribute | High-Pressure Processing (HPP) | Thermal Processing |

|---|---|---|

| Process Description | Applies 400-600 MPa pressure to inactivate microbes | Uses high heat (typically 85-121degC) to kill pathogens |

| Impact on Nutrients | Preserves vitamins, enzymes, and antioxidants | Can degrade heat-sensitive nutrients and enzymes |

| Microbial Safety | Effective against bacteria, yeasts, molds; spores less affected | Effective against bacteria, spores, yeasts, molds |

| Shelf Life | Extended shelf life without preservatives | Long shelf life but potential flavor changes |

| Flavor and Texture | Maintains fresh flavor and natural texture | May cause cooked flavor and altered texture |

| Energy Consumption | Lower energy use compared to thermal heating | High energy consumption due to heating requirements |

| Processing Time | Short treatment time (seconds to minutes) | Longer processing time (minutes to hours) |

| Regulatory Approval | Approved by FDA for juice safety | Widely accepted and standard method |

Introduction to Juice Processing Technologies

High-pressure processing (HPP) preserves juice quality by inactivating pathogens and spoilage microorganisms without heat, maintaining flavor, color, and nutrient content. Thermal processing relies on heat to ensure safety but often degrades sensory attributes and vitamins due to protein denaturation and Maillard reactions. HPP offers a non-thermal alternative that extends shelf life while retaining fresh-like characteristics, making it increasingly popular in the juice industry.

Principles of High-Pressure Processing (HPP)

High-Pressure Processing (HPP) utilizes ultra-high pressure, typically between 400 and 600 MPa, to inactivate pathogens and spoilage microorganisms in juice without significant heat application, preserving sensory and nutritional qualities. This non-thermal technique disrupts cellular membranes and denatures proteins by uniformly transmitting pressure through the liquid product, ensuring microbial safety while maintaining fresh taste and vitamins. Compared to traditional thermal processing, HPP offers enhanced retention of bioactive compounds and reduces thermal degradation, making it a superior method for juice preservation in food science.

Fundamentals of Thermal Processing in Juice Safety

Thermal processing in juice safety relies on applying controlled heat to inactivate pathogenic microorganisms and enzymes, ensuring microbial safety and extending shelf life. Key parameters include temperature, time, and pH, which influence microbial lethality and nutrient retention in juices. High-pressure processing offers an alternative by using pressure instead of heat, preserving sensory and nutritional qualities while achieving microbial inactivation without thermal degradation.

Microbial Inactivation: HPP vs Thermal Methods

High-pressure processing (HPP) inactivates microorganisms in juice by disrupting cellular membranes and denaturing proteins without significant heat, preserving nutritional and sensory qualities. Thermal processing relies on high temperatures to destroy pathogens and spoilage organisms but can cause nutrient degradation and alter flavor profiles. Comparative studies show HPP achieves microbial safety at lower temperatures, offering enhanced retention of juice quality while effectively reducing microbial load.

Impact on Juice Nutritional Quality

High-pressure processing (HPP) preserves juice nutritional quality by maintaining higher levels of vitamins, antioxidants, and enzymes compared to traditional thermal processing. Thermal processing often causes significant nutrient degradation, including loss of vitamin C and folate, due to heat exposure. Studies show HPP retains phytochemicals and sensory attributes better, ensuring safer juice without compromising its health benefits.

Sensory Attributes: Flavor, Color, and Texture

High-pressure processing (HPP) preserves the natural flavor, color, and texture of juice more effectively than thermal processing, which often causes nutrient degradation and off-flavors due to heat exposure. HPP maintains vibrant color by minimizing pigment breakdown and retains fresh-like taste by reducing enzymatic reactions. Texture remains closer to fresh juice with HPP, as it avoids the protein denaturation and structural changes caused by thermal pasteurization.

Retention of Vitamins and Bioactive Compounds

High-pressure processing (HPP) preserves higher levels of vitamins such as vitamin C and bioactive compounds like polyphenols in fruit juices compared to thermal processing, which often degrades these nutrients due to heat exposure. Studies show HPP maintains antioxidant activity and nutritional quality, enhancing juice safety without compromising health benefits. Thermal processing guarantees microbial safety but results in significant losses of sensitive vitamins and phytochemicals, affecting overall nutritional value.

Shelf-life Extension and Spoilage Prevention

High-pressure processing (HPP) significantly extends the shelf-life of juices by inactivating spoilage microorganisms and enzymes without compromising nutritional quality or sensory attributes. Thermal processing effectively eliminates pathogens and prolongs shelf-life but often leads to nutrient degradation and altered flavor profiles. HPP provides superior spoilage prevention by maintaining juice freshness longer while minimizing thermal damage compared to traditional heat treatments.

Consumer Perception and Market Trends

High-pressure processing (HPP) preserves fresh-like taste and nutrients in juices better than traditional thermal processing, which often alters flavor and nutrient content. Consumer preference is increasingly shifting towards HPP-treated juices due to perceptions of higher quality, safety, and naturalness. Market trends indicate a growing demand for minimally processed, clean-label beverages, driving juice manufacturers to adopt HPP technology.

Future Prospects in Juice Processing Technologies

High-pressure processing (HPP) offers a non-thermal alternative to traditional thermal processing, preserving nutrients and flavor while effectively inactivating pathogens in juices. Emerging innovations in HPP technology aim to enhance energy efficiency and reduce processing times, increasing its commercial viability. Future prospects in juice processing emphasize integrating HPP with other non-thermal methods to achieve superior microbial safety and extended shelf life without compromising quality.

Related Important Terms

Cold Pasteurization

High-pressure processing (HPP) offers cold pasteurization by inactivating pathogens and spoilage microorganisms in juice without heat, preserving nutrients and sensory qualities more effectively than traditional thermal pasteurization. This non-thermal method maintains vitamin content and fresh flavor while ensuring microbial safety, making it a superior alternative for juice preservation.

Non-Thermal Hurdle Technology

High-pressure processing (HPP) preserves juice safety by inactivating pathogens and spoilage microorganisms without compromising nutritional and sensory qualities, offering a superior non-thermal hurdle technology compared to conventional thermal pasteurization. This method maintains bioactive compounds and vitamins, extending shelf life while minimizing heat-induced degradation commonly associated with thermal processing.

Pressure-Assisted Thermal Sterilization (PATS)

Pressure-Assisted Thermal Sterilization (PATS) combines high hydrostatic pressure with moderate heat to inactivate microbial pathogens in fruit juices more effectively than conventional thermal processing, while preserving sensory and nutritional quality. This technology achieves commercial sterility by reducing heat exposure time, minimizing degradation of vitamins and flavor compounds, and enhancing juice safety through synergistic pressure-heat microbial inactivation mechanisms.

Barocycling

High-pressure processing (HPP), particularly Barocycling, inactivates pathogens and spoilage microorganisms in juice by applying repeated cycles of pressure changes, preserving sensory and nutritional qualities better than conventional thermal processing. Barocycling enhances microbial safety by disrupting cell membranes through pressure fluctuations, minimizing heat-induced degradation and maintaining vitamin C retention and fresh flavor in juice products.

Spore Inactivation Dynamics

High-pressure processing (HPP) achieves significant spore inactivation in juices by disrupting cellular structures under pressures of 400-600 MPa, maintaining nutritional and sensory quality better than thermal processing, which relies on high temperatures above 90degC that often degrade heat-sensitive nutrients. Spore inactivation dynamics reveal that HPP combined with mild heat (40-60degC) synergistically enhances spore germination and lethality, offering a safer alternative to conventional thermal pasteurization without compromising juice freshness.

Manosonication

High-pressure processing (HPP) and thermal processing are both effective in enhancing juice safety by inactivating pathogens, but manosonication combines ultrasonic waves with mild heat to disrupt microbial cells more efficiently while preserving juice quality. This synergistic technology leverages cavitation and mechanical shear forces to achieve superior microbial reduction compared to conventional thermal pasteurization, maintaining nutritional and sensory properties of the juice.

Isochoric Processing

Isochoric processing maintains juice safety by applying high pressure within a constant volume, effectively inactivating pathogens without the nutrient loss typical of thermal processing. Unlike conventional thermal methods, this technique preserves flavor, color, and bioactive compounds while ensuring microbial stability.

Pressure-Temperature-Time Equivalence

High-pressure processing (HPP) and thermal processing ensure juice safety by inactivating pathogens through distinct Pressure-Temperature-Time (PTT) equivalence mechanisms, where HPP utilizes pressures of 400-600 MPa combined with moderate temperatures (20-50degC) over short times to preserve flavor and nutrients. Thermal processing typically requires higher temperatures (90-121degC) for rapid microbial inactivation but risks quality degradation, highlighting that precise PTT optimization in HPP achieves microbial safety with minimal impact on juice sensory and nutritional properties.

Thermosonication

Thermosonication combines thermal treatment with ultrasound waves to enhance microbial inactivation in juices, offering improved retention of nutrients and sensory qualities compared to traditional thermal processing. High-pressure processing (HPP) maintains juice freshness and bioactive compounds effectively but thermosonication provides superior microbial safety by disrupting cell membranes through cavitation and mild heat, optimizing juice shelf life and quality.

Enzyme Retention Index

High-pressure processing (HPP) preserves a higher Enzyme Retention Index (ERI) in juice by inactivating spoilage microbes while maintaining enzyme functionality, compared to thermal processing which often denatures enzymes due to heat exposure. Research indicates HPP-treated juices retain over 80% ERI, enhancing nutritional and sensory qualities, whereas thermal methods typically reduce ERI below 50%, adversely affecting juice quality.

High-pressure processing vs thermal processing for juice safety Infographic

agridif.com

agridif.com