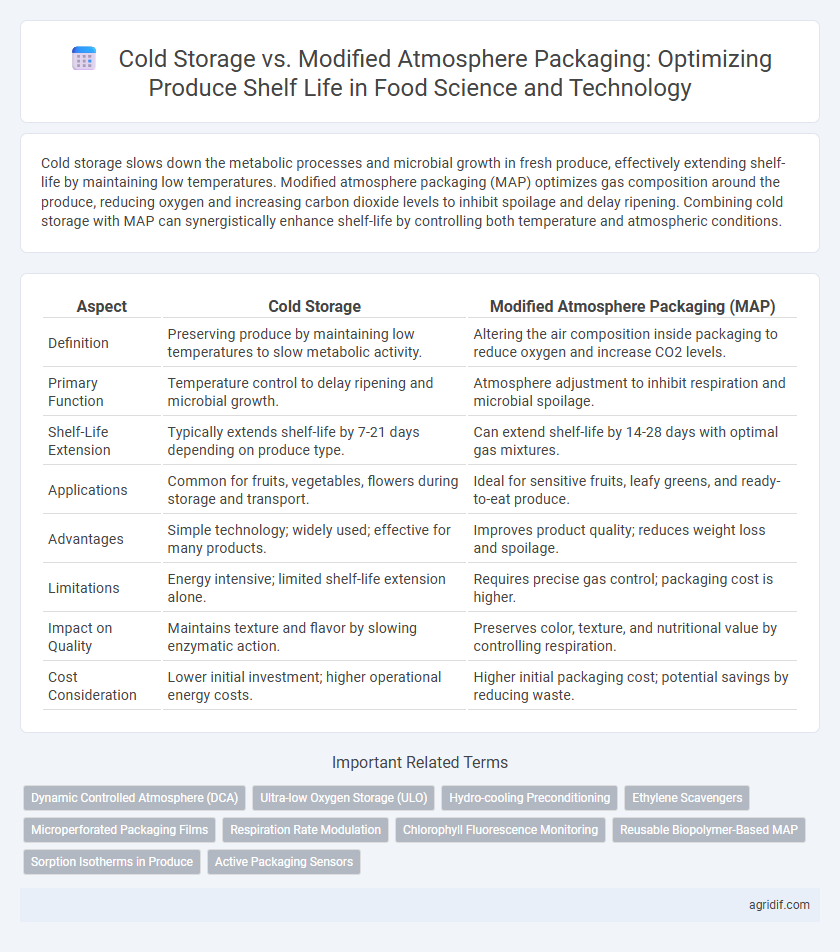

Cold storage slows down the metabolic processes and microbial growth in fresh produce, effectively extending shelf-life by maintaining low temperatures. Modified atmosphere packaging (MAP) optimizes gas composition around the produce, reducing oxygen and increasing carbon dioxide levels to inhibit spoilage and delay ripening. Combining cold storage with MAP can synergistically enhance shelf-life by controlling both temperature and atmospheric conditions.

Table of Comparison

| Aspect | Cold Storage | Modified Atmosphere Packaging (MAP) |

|---|---|---|

| Definition | Preserving produce by maintaining low temperatures to slow metabolic activity. | Altering the air composition inside packaging to reduce oxygen and increase CO2 levels. |

| Primary Function | Temperature control to delay ripening and microbial growth. | Atmosphere adjustment to inhibit respiration and microbial spoilage. |

| Shelf-Life Extension | Typically extends shelf-life by 7-21 days depending on produce type. | Can extend shelf-life by 14-28 days with optimal gas mixtures. |

| Applications | Common for fruits, vegetables, flowers during storage and transport. | Ideal for sensitive fruits, leafy greens, and ready-to-eat produce. |

| Advantages | Simple technology; widely used; effective for many products. | Improves product quality; reduces weight loss and spoilage. |

| Limitations | Energy intensive; limited shelf-life extension alone. | Requires precise gas control; packaging cost is higher. |

| Impact on Quality | Maintains texture and flavor by slowing enzymatic action. | Preserves color, texture, and nutritional value by controlling respiration. |

| Cost Consideration | Lower initial investment; higher operational energy costs. | Higher initial packaging cost; potential savings by reducing waste. |

Introduction to Post-Harvest Preservation Methods

Cold storage slows down the metabolic rate and microbial growth in fresh produce by maintaining temperatures just above freezing, effectively extending shelf life while preserving nutritional quality. Modified Atmosphere Packaging (MAP) alters the gas composition around the produce, reducing oxygen and increasing carbon dioxide levels to delay ripening and inhibit spoilage organisms. Combining cold storage with MAP synergistically enhances shelf-life extension by optimizing environmental conditions and minimizing physiological deterioration post-harvest.

Understanding Cold Storage Technology

Cold storage technology effectively prolongs produce shelf-life by maintaining low temperatures that slow metabolic rates and microbial growth. This method preserves nutritional quality and firmness while reducing spoilage without altering the atmospheric composition surrounding the produce. Optimizing temperature control and humidity levels in cold storage is critical to minimizing enzymatic activity and delaying senescence in fruits and vegetables.

Principles of Modified Atmosphere Packaging (MAP)

Modified Atmosphere Packaging (MAP) extends produce shelf-life by altering the gas composition surrounding the product, typically reducing oxygen and increasing carbon dioxide and nitrogen levels to slow respiration and microbial growth. This controlled atmosphere slows enzymatic activity and delays ripening compared to conventional cold storage, which primarily relies on low temperatures to reduce metabolic rates. MAP enables customized gas mixtures tailored to specific fruits or vegetables, optimizing freshness and quality while minimizing moisture loss and spoilage.

Comparing Shelf-Life Extension: Cold Storage vs MAP

Cold storage slows metabolic processes and microbial growth by maintaining low temperatures, effectively extending produce shelf-life by several days to weeks depending on the commodity. Modified atmosphere packaging (MAP) alters the gas composition around the produce, reducing oxygen and increasing carbon dioxide levels to inhibit respiration and delay spoilage, often doubling or tripling shelf-life compared to ambient conditions. Combining cold storage with MAP can synergistically enhance shelf-life extension by leveraging both temperature control and atmospheric modification for optimal freshness retention.

Temperature Control: Effectiveness and Limitations

Cold storage maintains produce at consistently low temperatures, significantly slowing metabolic processes and microbial growth to extend shelf-life effectively. Modified atmosphere packaging (MAP) alters the gaseous environment around produce but offers limited temperature control, making it less effective in inhibiting enzymatic activity compared to cold storage. Temperature fluctuations in MAP can accelerate spoilage, emphasizing cold storage's superiority in preserving quality through precise thermal regulation.

Gas Composition and Its Impact on Produce Quality

Gas composition in cold storage typically involves maintaining low oxygen (O2) and elevated carbon dioxide (CO2) levels to slow respiration rates and delay spoilage, preserving produce firmness and color retention. Modified atmosphere packaging (MAP) fine-tunes gas concentrations within sealed environments, often optimizing O2 between 1-5% and CO2 between 5-15%, which helps reduce ethylene production and microbial growth, thereby extending shelf life. Precise control of gas mixtures in MAP proves more effective than conventional cold storage alone in maintaining produce quality by minimizing oxidative stress and maintaining optimal metabolic conditions.

Energy Consumption and Environmental Impact

Cold storage extends produce shelf-life by maintaining low temperatures, but it consumes significant energy due to continuous refrigeration, leading to higher greenhouse gas emissions. Modified atmosphere packaging (MAP) reduces respiration rates and delays spoilage by altering gas composition around the produce, resulting in lower energy usage and reduced carbon footprint compared to cold storage. Integrating MAP with optimized cold storage can minimize overall environmental impact while enhancing shelf-life and reducing food waste.

Cost Analysis: Cold Storage vs MAP Systems

Cold storage demands significant energy consumption and infrastructure investments, resulting in higher operational costs for extended produce preservation. Modified Atmosphere Packaging (MAP) systems involve initial costs for specialized materials and packaging machinery but can lower energy expenses and waste by reducing spoilage. Analyzing the total cost of ownership reveals MAP as a cost-effective solution for retailers aiming to balance shelf-life extension with budget constraints.

Suitability for Different Types of Produce

Cold storage is highly effective for fruits and vegetables with low respiration rates, such as apples and potatoes, by maintaining low temperatures to slow metabolic activities and delay spoilage. Modified atmosphere packaging (MAP) is more suitable for high-respiration produce like berries and leafy greens, as it adjusts oxygen and carbon dioxide levels to reduce respiration and extend freshness without compromising texture. Combining cold storage and MAP can optimize shelf-life, especially for sensitive produce requiring both temperature control and atmospheric modification.

Future Trends in Produce Preservation Technologies

Cold storage remains essential for extending produce shelf-life but faces challenges in energy consumption and quality retention. Modified atmosphere packaging (MAP) innovates this sector by optimizing gas compositions to slow respiration and microbial growth while preserving texture and flavor. Future trends in produce preservation emphasize integrating smart sensors and nanotechnology with MAP to dynamically monitor and control environmental conditions, reducing waste and enhancing freshness.

Related Important Terms

Dynamic Controlled Atmosphere (DCA)

Dynamic Controlled Atmosphere (DCA) technology enhances produce shelf-life by continuously adjusting oxygen, carbon dioxide, and humidity levels based on real-time measurements, reducing respiration rates and delaying ripening more effectively than traditional cold storage or static Modified Atmosphere Packaging (MAP). Unlike MAP, which sets fixed gas compositions, DCA's adaptive control optimizes fruit quality and extends freshness while minimizing physiological disorders and microbial growth during storage.

Ultra-low Oxygen Storage (ULO)

Ultra-low oxygen storage (ULO) extends produce shelf-life by maintaining oxygen levels typically below 1%, reducing respiration rates and delaying ripening compared to conventional cold storage. Modified atmosphere packaging (MAP) complements ULO by creating an optimized gas mixture around the produce, enhancing freshness retention through controlled oxygen, carbon dioxide, and humidity levels.

Hydro-cooling Preconditioning

Hydro-cooling preconditioning significantly enhances produce shelf-life by rapidly reducing field heat, thereby maintaining texture and nutritional quality more effectively than traditional cold storage alone. When combined with modified atmosphere packaging, this method optimizes gas exchange and moisture retention, further extending freshness and reducing postharvest losses.

Ethylene Scavengers

Cold storage slows down ethylene production and respiration rates in fresh produce, extending shelf life by maintaining low temperatures and high humidity. Modified atmosphere packaging combined with ethylene scavengers, such as potassium permanganate or activated carbon, actively reduces ethylene concentration around the produce, significantly delaying ripening and senescence compared to cold storage alone.

Microperforated Packaging Films

Microperforated packaging films in modified atmosphere packaging effectively regulate gas exchange, reducing respiration rates and extending produce shelf-life compared to traditional cold storage. These films balance oxygen and carbon dioxide levels, minimizing microbial growth and moisture loss while maintaining optimal freshness.

Respiration Rate Modulation

Cold storage effectively slows the respiration rate of produce by reducing temperature, thereby delaying ripening and senescence. Modified atmosphere packaging (MAP) optimizes gas composition around the produce, lowering oxygen and increasing carbon dioxide levels, which further suppresses respiration rate and extends shelf-life.

Chlorophyll Fluorescence Monitoring

Chlorophyll fluorescence monitoring effectively evaluates produce freshness by detecting physiological changes during cold storage, revealing stress responses that influence shelf-life. In comparison, modified atmosphere packaging alters gas compositions to slow chlorophyll degradation, with fluorescence data indicating superior maintenance of photosynthetic efficiency and delayed senescence.

Reusable Biopolymer-Based MAP

Reusable biopolymer-based Modified Atmosphere Packaging (MAP) significantly extends produce shelf-life by reducing oxygen levels and controlling humidity, which inhibits microbial growth and enzymatic degradation more effectively than traditional cold storage. Combining cold storage with biopolymer-based MAP creates a synergistic effect that optimizes freshness retention, reduces plastic waste, and enhances sustainability in food preservation.

Sorption Isotherms in Produce

Sorption isotherms play a critical role in understanding moisture equilibrium between produce and its environment, directly impacting shelf-life preservation in both cold storage and modified atmosphere packaging (MAP). Cold storage maintains low temperatures to reduce metabolic activity and moisture loss, whereas MAP optimizes gas composition around produce, influencing sorption isotherms to better control water activity and delay spoilage.

Active Packaging Sensors

Active packaging sensors in modified atmosphere packaging (MAP) provide real-time monitoring of produce freshness by detecting gas composition changes like oxygen and carbon dioxide levels, enhancing shelf-life control beyond traditional cold storage methods. Integrating these sensors with MAP optimizes produce quality and reduces spoilage compared to cold storage alone, which primarily relies on temperature regulation without continuous freshness assessment.

Cold storage vs Modified atmosphere packaging for produce shelf-life Infographic

agridif.com

agridif.com