Spray drying rapidly converts liquid ingredients into fine powders by atomizing the feed into a hot air chamber, preserving flavor and nutrients efficiently for large-scale production. Freeze drying removes moisture through sublimation under low temperatures, maintaining superior product stability and retaining sensitive bioactive compounds with minimal structural damage. Both methods offer distinct advantages in powdered ingredient processing, with spray drying suited for heat-stable materials and freeze drying preferred for heat-sensitive or high-value formulations.

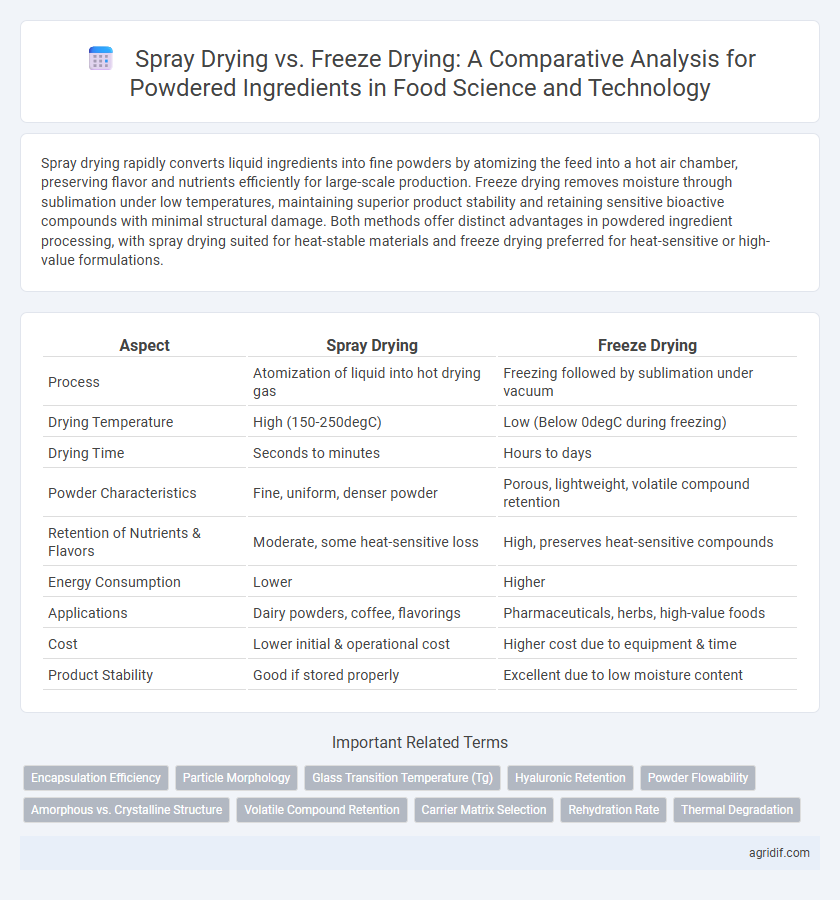

Table of Comparison

| Aspect | Spray Drying | Freeze Drying |

|---|---|---|

| Process | Atomization of liquid into hot drying gas | Freezing followed by sublimation under vacuum |

| Drying Temperature | High (150-250degC) | Low (Below 0degC during freezing) |

| Drying Time | Seconds to minutes | Hours to days |

| Powder Characteristics | Fine, uniform, denser powder | Porous, lightweight, volatile compound retention |

| Retention of Nutrients & Flavors | Moderate, some heat-sensitive loss | High, preserves heat-sensitive compounds |

| Energy Consumption | Lower | Higher |

| Applications | Dairy powders, coffee, flavorings | Pharmaceuticals, herbs, high-value foods |

| Cost | Lower initial & operational cost | Higher cost due to equipment & time |

| Product Stability | Good if stored properly | Excellent due to low moisture content |

Introduction to Drying Technologies in Food Science

Spray drying and freeze drying are essential dehydration methods in food science that transform liquid ingredients into stable powdered forms. Spray drying utilizes hot air to rapidly evaporate moisture, creating fine, free-flowing powders ideal for heat-sensitive vitamins and flavor retention. Freeze drying, or lyophilization, removes moisture through sublimation under low temperature and pressure, preserving nutritional quality and extending shelf life in high-value powdered ingredients.

Principles of Spray Drying and Freeze Drying

Spray drying involves atomizing a liquid feed into a hot drying chamber, rapidly evaporating moisture to produce fine, uniform powder particles ideal for heat-sensitive food ingredients. Freeze drying, or lyophilization, sublimates frozen water under low pressure, preserving the molecular structure and nutritional quality of ingredients by avoiding high temperatures. Both techniques enable the transformation of liquid food products into stable powders but differ significantly in drying mechanisms and thermal exposure.

Process Workflow: Spray Drying vs Freeze Drying

Spray drying involves atomizing liquid ingredients into a hot drying chamber, rapidly evaporating moisture to produce fine powder particles with controlled size and moisture content. Freeze drying, or lyophilization, freezes the material and removes moisture under a vacuum through sublimation, preserving heat-sensitive nutrients and bioactive compounds. The spray drying workflow is faster and more energy-efficient, while freeze drying offers superior retention of flavor, texture, and nutritional quality but requires longer processing times and higher operational costs.

Impact on Nutritional Quality of Ingredients

Spray drying exposes powdered ingredients to high temperatures for short durations, often causing partial degradation of heat-sensitive vitamins like vitamin C and certain B-complex vitamins, potentially reducing overall nutritional quality. Freeze drying, by removing moisture under low temperature and vacuum conditions, better preserves heat-labile nutrients, antioxidants, and bioactive compounds, maintaining the ingredient's original nutritional profile. Comparative studies indicate freeze drying retains up to 90-95% of nutritional components, whereas spray drying retention rates vary widely from 60-80%, depending on process parameters.

Effects on Flavor, Color, and Aroma Retention

Spray drying preserves flavor, color, and aroma efficiently by rapidly removing moisture through hot air, though some volatile compounds may degrade due to heat exposure. Freeze drying excels in retaining delicate flavors, vibrant colors, and natural aromas by sublimating ice under low temperature and pressure, minimizing thermal degradation. Both methods impact sensory quality, with freeze drying generally offering superior retention for heat-sensitive powdered ingredients in food science applications.

Powder Properties: Solubility, Flowability, and Particle Size

Spray drying produces powders with smaller, more uniform particles that enhance solubility due to increased surface area, while freeze drying often yields larger, porous particles that improve rehydration but may reduce flowability. Powders from spray drying generally exhibit superior flowability because of their spherical shape and consistent size distribution, whereas freeze-dried powders tend to be more irregular and fragile, impacting handling and processing efficiency. Choosing between spray drying and freeze drying depends on the desired balance of solubility, flowability, and particle size tailored to specific powdered ingredient applications in food science.

Energy Consumption and Operational Costs

Spray drying consumes significantly more energy compared to freeze drying due to the high-temperature air required for rapid moisture removal, leading to elevated operational costs. Freeze drying involves sublimation under low temperature and pressure, resulting in lower energy efficiency but superior product preservation and extended shelf life, which can offset higher initial expenses. Choosing between these methods depends on balancing energy consumption with product quality and cost-effectiveness in powdered ingredient production.

Suitability for Heat-Sensitive Ingredients

Spray drying rapidly removes moisture by spraying the liquid ingredient into hot air, making it less suitable for heat-sensitive ingredients due to potential nutrient degradation and flavor loss. Freeze drying preserves heat-sensitive compounds by sublimating frozen water under low temperature and pressure, maintaining nutritional quality and sensory attributes. This method is ideal for powdered ingredients like probiotics, enzymes, and vitamins that require minimal thermal exposure.

Applications in the Food Industry

Spray drying is widely applied in the food industry for producing powdered ingredients such as milk powder, coffee, and flavor encapsulates due to its fast drying time and ability to retain aroma and solubility. Freeze drying preserves sensitive nutrients and bioactive compounds, making it ideal for probiotic powders, fruit powders, and instant soups with enhanced shelf life and nutritional quality. Both methods serve distinct roles, with spray drying favored for cost-effective bulk production and freeze drying preferred for high-value, heat-sensitive food products.

Sustainability and Environmental Considerations

Spray drying consumes less energy and has a faster processing time compared to freeze drying, making it more sustainable for large-scale production of powdered ingredients. Freeze drying, while energy-intensive due to low temperature and vacuum requirements, better preserves nutritional and sensory qualities, reducing food waste. Both methods impact carbon footprint differently, with spray drying favoring lower emissions but freeze drying offering advantages in ingredient stability and shelf life, influencing overall environmental sustainability.

Related Important Terms

Encapsulation Efficiency

Spray drying achieves high encapsulation efficiency for heat-sensitive bioactive compounds by rapidly forming a protective matrix around particles, while freeze drying preserves ingredient integrity with minimal thermal degradation but often results in lower encapsulation efficiencies due to porous structures. Optimizing inlet air temperature and feed composition in spray drying enhances encapsulation efficiency, whereas freeze drying benefits from controlled freezing rates to maintain encapsulate stability in powdered ingredients.

Particle Morphology

Spray drying produces spherical particles with smooth surfaces and uniform size distribution, enhancing flowability and solubility in powdered ingredients. Freeze drying generates porous, irregularly shaped particles with high surface area, improving rehydration rates but often resulting in fragile powders prone to caking.

Glass Transition Temperature (Tg)

Spray drying involves rapid moisture removal at elevated temperatures, requiring careful control of glass transition temperature (Tg) to prevent powder stickiness and caking, while freeze drying operates below Tg, preserving the structural integrity and stability of powdered ingredients by maintaining a glassy, amorphous state. Understanding and manipulating Tg during spray drying enhances powder flowability and shelf life, whereas in freeze drying, maintaining Tg ensures minimal molecular mobility and superior preservation of bioactive compounds.

Hyaluronic Retention

Spray drying involves rapid moisture removal at elevated temperatures, which can lead to significant hyaluronic acid degradation, whereas freeze drying preserves hyaluronic acid content by sublimating ice under low temperature and pressure conditions. Research shows freeze drying retains up to 90% of hyaluronic acid bioactivity, compared to spray drying's 50-60%, making freeze drying preferable for maintaining hyaluronic retention in powdered ingredients.

Powder Flowability

Spray drying produces powders with smaller, more uniform particles that typically exhibit better flowability due to reduced inter-particle cohesion and lower moisture content. Freeze drying results in porous, irregularly shaped particles that often have poor flow properties, increasing the risk of caking and handling difficulties in powdered ingredient applications.

Amorphous vs. Crystalline Structure

Spray drying typically produces powders with an amorphous structure due to rapid solvent evaporation, enhancing solubility and bioavailability of powdered ingredients. Freeze drying, by contrast, preserves crystalline structure through sublimation of frozen solvent, resulting in powders with greater stability and longer shelf life in food applications.

Volatile Compound Retention

Spray drying often leads to significant loss of volatile compounds due to high processing temperatures, while freeze drying preserves these aromas better by operating at low temperatures and reduced pressure. Freeze drying maintains the sensory quality and potency of powdered ingredients, making it preferable for heat-sensitive volatile compounds in food applications.

Carrier Matrix Selection

Carrier matrix selection critically influences the efficiency and quality of both spray drying and freeze drying for powdered food ingredients, with maltodextrin commonly enhancing spray drying by improving powder flow and solubility, while gelatin and gum arabic serve as effective carriers in freeze drying by preserving bioactive compounds and structural integrity. Optimizing the carrier matrix ensures stability, encapsulation efficiency, and reconstitution properties tailored to the drying technique and ingredient functionality in food science applications.

Rehydration Rate

Spray drying produces powdered ingredients with smaller, porous particles that typically exhibit faster rehydration rates due to increased surface area and improved water absorption. Freeze drying creates highly porous and fragile particles with interconnected pore structures, often resulting in even quicker rehydration by facilitating rapid water penetration and swelling.

Thermal Degradation

Spray drying involves high temperatures that can cause significant thermal degradation of heat-sensitive nutrients and bioactive compounds in powdered ingredients, leading to nutrient loss and altered flavor profiles. Freeze drying preserves the integrity of these thermally labile compounds by sublimating moisture under low temperature and pressure, minimizing nutrient degradation and maintaining higher product quality.

Spray Drying vs Freeze Drying for Powdered Ingredients Infographic

agridif.com

agridif.com