Modified Atmosphere Packaging (MAP) extends meat shelf life by replacing oxygen with a gas mixture, typically carbon dioxide and nitrogen, which inhibits microbial growth and preserves color better than vacuum packaging. Vacuum packaging removes air entirely, slowing spoilage but often resulting in a darker meat color and potential texture changes. Both methods enhance shelf life, but MAP offers superior visual appeal and aerobic bacteria control, making it ideal for retail display.

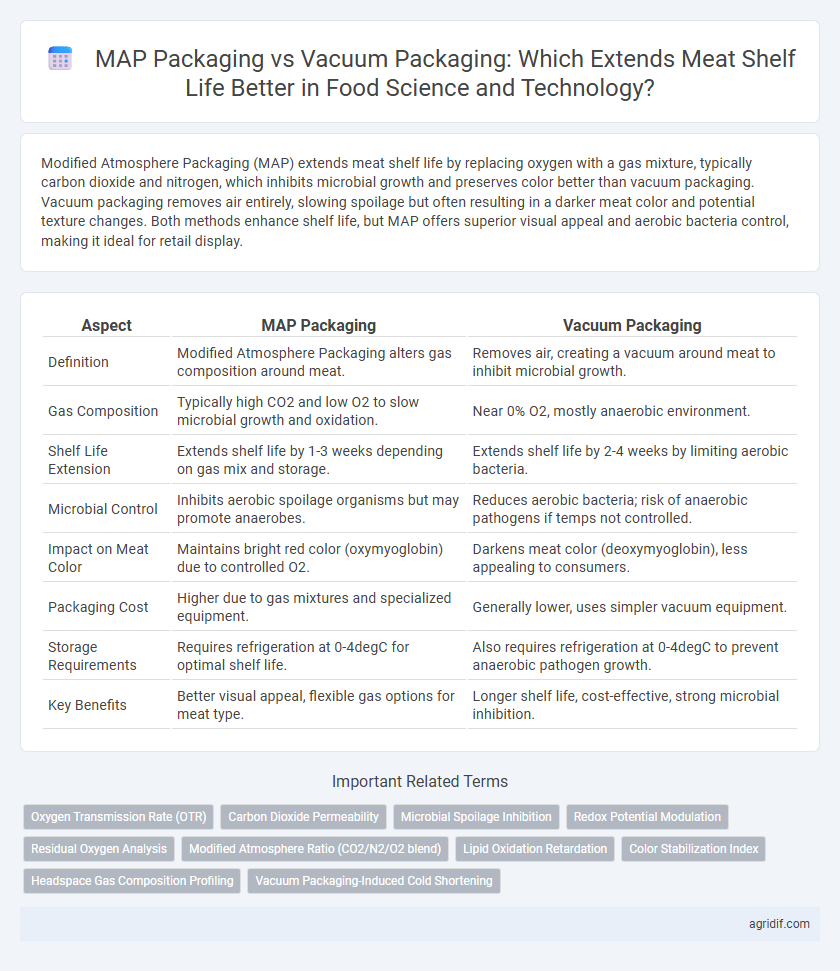

Table of Comparison

| Aspect | MAP Packaging | Vacuum Packaging |

|---|---|---|

| Definition | Modified Atmosphere Packaging alters gas composition around meat. | Removes air, creating a vacuum around meat to inhibit microbial growth. |

| Gas Composition | Typically high CO2 and low O2 to slow microbial growth and oxidation. | Near 0% O2, mostly anaerobic environment. |

| Shelf Life Extension | Extends shelf life by 1-3 weeks depending on gas mix and storage. | Extends shelf life by 2-4 weeks by limiting aerobic bacteria. |

| Microbial Control | Inhibits aerobic spoilage organisms but may promote anaerobes. | Reduces aerobic bacteria; risk of anaerobic pathogens if temps not controlled. |

| Impact on Meat Color | Maintains bright red color (oxymyoglobin) due to controlled O2. | Darkens meat color (deoxymyoglobin), less appealing to consumers. |

| Packaging Cost | Higher due to gas mixtures and specialized equipment. | Generally lower, uses simpler vacuum equipment. |

| Storage Requirements | Requires refrigeration at 0-4degC for optimal shelf life. | Also requires refrigeration at 0-4degC to prevent anaerobic pathogen growth. |

| Key Benefits | Better visual appeal, flexible gas options for meat type. | Longer shelf life, cost-effective, strong microbial inhibition. |

Introduction to Meat Packaging Technologies

Modified atmosphere packaging (MAP) extends meat shelf life by altering the gas composition surrounding the product, typically using a blend of oxygen, carbon dioxide, and nitrogen to inhibit microbial growth and oxidation. Vacuum packaging removes air completely, creating anaerobic conditions that reduce aerobic spoilage bacteria and oxidative rancidity, thereby preserving meat freshness. Both technologies enhance shelf life but differ in gas composition control and effects on meat color, texture, and microbial stability.

Principles of Modified Atmosphere Packaging (MAP)

Modified Atmosphere Packaging (MAP) extends meat shelf life by altering the gas composition inside the package, typically increasing oxygen, carbon dioxide, and nitrogen levels to inhibit microbial growth and oxidation. Oxygen maintains meat color by promoting oxymyoglobin formation, while elevated carbon dioxide suppresses spoilage bacteria, enhancing freshness without compromising texture. In contrast, vacuum packaging removes air entirely, which limits aerobic bacteria but can cause color changes and anaerobic environments that may favor different microbial risks.

Fundamentals of Vacuum Packaging for Meat

Vacuum packaging for meat involves removing air to create an anaerobic environment that significantly reduces microbial growth and oxidation, thereby extending shelf life. This method maintains the meat's color, moisture, and nutrient content by minimizing exposure to oxygen, which is a primary factor in spoilage. In comparison to Modified Atmosphere Packaging (MAP), vacuum packaging provides a more consistent and longer-lasting preservation effect by preventing aerobic bacteria proliferation.

Comparative Effects on Meat Shelf Life

Modified Atmosphere Packaging (MAP) extends meat shelf life by altering the gas composition around the product, typically using high oxygen or carbon dioxide levels to inhibit microbial growth and oxidation. Vacuum packaging removes air entirely, significantly reducing oxygen and slowing spoilage by limiting aerobic bacteria development while preserving meat color and texture. Comparative studies show MAP often maintains freshness and appearance longer, but vacuum packaging excels in extending shelf life by better controlling microbial spoilage under anaerobic conditions.

Impact on Meat Quality and Freshness

Modified Atmosphere Packaging (MAP) extends meat shelf life by replacing oxygen with a gas mix, typically carbon dioxide and nitrogen, which inhibits microbial growth while preserving color and texture better than vacuum packaging. Vacuum packaging removes air entirely, effectively reducing oxidation and microbial spoilage but can cause muscle compression, leading to altered texture and color that may affect consumer perception. Comparative studies reveal MAP maintains meat freshness and sensory attributes longer, making it preferable for premium cuts requiring extended display times.

Microbial Control: MAP vs Vacuum Packaging

Modified Atmosphere Packaging (MAP) extends meat shelf life by replacing oxygen with gases such as carbon dioxide and nitrogen, which inhibit aerobic microbial growth and oxidative spoilage. Vacuum packaging removes air entirely, creating anaerobic conditions that limit aerobic bacteria but may allow growth of anaerobic pathogens like Clostridium species. Studies indicate MAP offers superior control over spoilage organisms due to optimized gas blends, while vacuum packaging excels in reducing oxygen-dependent microbes but requires careful monitoring of anaerobic pathogen risks.

Influence on Color and Sensory Attributes

Modified Atmosphere Packaging (MAP) preserves meat color by maintaining a high oxygen environment, enhancing the bright red appearance preferred by consumers, while vacuum packaging typically results in a darker purple hue due to oxygen depletion. MAP also tends to better retain sensory attributes such as texture and juiciness by reducing oxidative rancidity and microbial growth compared to vacuum-packaged meat. However, vacuum packaging extends shelf life more effectively by creating anaerobic conditions that inhibit spoilage organisms, though it may sacrifice immediate visual appeal.

Packaging Materials and Technologies Used

Modified Atmosphere Packaging (MAP) employs high-barrier films combined with gas mixtures such as oxygen, carbon dioxide, and nitrogen that inhibit microbial growth and oxidation in meat, effectively extending shelf life. Vacuum packaging utilizes multilayer laminates with oxygen-impermeable properties to remove air and prevent aerobic spoilage, maintaining meat quality under anaerobic conditions. Innovations like metallized films and nanocomposite layers enhance gas barrier performance in both MAP and vacuum packaging, optimizing protection and freshness retention for meat products.

Cost Efficiency and Commercial Applicability

MAP packaging extends meat shelf life by maintaining product freshness through controlled gas mixtures, offering flexible packaging options that reduce spoilage-related costs. Vacuum packaging provides longer shelf life by removing oxygen and inhibiting microbial growth but may increase packaging material costs and limit product presentation appeal. Commercially, MAP suits high-volume retail environments requiring visual product appeal, while vacuum packaging is cost-effective for bulk storage and transport with less emphasis on display.

Future Trends in Meat Packaging Solutions

Modified Atmosphere Packaging (MAP) enhances meat shelf life by controlling gas compositions to inhibit microbial growth and oxidative spoilage, showing potential for integration with active packaging materials. Vacuum packaging reduces oxygen exposure, effectively preventing aerobic microbial proliferation and lipid oxidation, but may impact meat color and texture, prompting innovation in multi-layer films and barrier technologies. Emerging trends emphasize combining MAP with nanotechnology and biosensors to monitor freshness in real-time, advancing sustainable and intelligent meat packaging solutions.

Related Important Terms

Oxygen Transmission Rate (OTR)

Modified Atmosphere Packaging (MAP) utilizes controlled gas compositions to reduce Oxygen Transmission Rate (OTR), effectively slowing oxidation and microbial growth in meat products, thereby extending shelf life. Vacuum packaging achieves low OTR by removing air and minimizing oxygen exposure, but MAP offers more precise control over gas mixtures, resulting in optimized preservation and improved color stability in fresh meat.

Carbon Dioxide Permeability

Modified atmosphere packaging (MAP) with controlled carbon dioxide permeability enhances meat shelf life by inhibiting microbial growth and oxidation more effectively than vacuum packaging, which limits oxygen but does not regulate CO2 levels. Optimal CO2 permeability in MAP maintains meat color and texture, extending freshness while preventing anaerobic spoilage common in vacuum-packaged meat.

Microbial Spoilage Inhibition

Modified Atmosphere Packaging (MAP) extends meat shelf life by reducing oxygen levels and increasing carbon dioxide concentration, which inhibits aerobic microbial growth and delays spoilage. Vacuum packaging removes air entirely, creating an anaerobic environment that prevents oxidative spoilage but may promote growth of certain anaerobic bacteria, making MAP more effective in controlling microbial spoilage for fresh meat products.

Redox Potential Modulation

Modified Atmosphere Packaging (MAP) extends meat shelf life by modulating redox potential through controlled oxygen and carbon dioxide levels, which inhibit oxidative spoilage and microbial growth more effectively than vacuum packaging. Vacuum packaging reduces oxygen availability but can lead to a more reductive environment that favors anaerobic spoilage organisms, making MAP superior in maintaining meat quality and color stability via optimized redox balance.

Residual Oxygen Analysis

MAP packaging extends meat shelf life by maintaining a controlled atmosphere with low residual oxygen levels, reducing oxidative spoilage and microbial growth. Vacuum packaging achieves minimal residual oxygen through air removal, but MAP's optimized gas mixtures better preserve color and freshness while inhibiting aerobic bacteria.

Modified Atmosphere Ratio (CO2/N2/O2 blend)

Modified Atmosphere Packaging (MAP) extends meat shelf life by optimizing the gas blend, commonly using 40-60% CO2 to inhibit microbial growth, balanced with N2 as an inert filler and 10-20% O2 to maintain meat color and freshness; this precise CO2/N2/O2 ratio outperforms vacuum packaging by better preserving sensory qualities and reducing drip loss. Vacuum packaging removes oxygen entirely, slowing oxidation but often causing color darkening and increased exudate, whereas controlled MAP gas mixtures allow for longer display periods with maintained visual appeal and microbial stability.

Lipid Oxidation Retardation

Modified atmosphere packaging (MAP) significantly retards lipid oxidation in meat by limiting oxygen exposure through controlled gas mixtures, primarily using nitrogen and carbon dioxide. Vacuum packaging also reduces oxidation by removing air entirely, but MAP provides better oxidative stability due to its ability to maintain moisture and inhibit microbial growth, extending meat shelf life effectively.

Color Stabilization Index

Modified Atmosphere Packaging (MAP) significantly enhances the Color Stabilization Index (CSI) of meat by maintaining higher oxygen levels that preserve the bright red oxymyoglobin pigment, extending visual freshness up to 7-10 days compared to vacuum packaging. Vacuum packaging, while effective in inhibiting microbial growth, results in lower CSI due to deoxygenation, leading to a darker purplish hue from deoxymyoglobin that reduces consumer appeal within 3-5 days.

Headspace Gas Composition Profiling

Modified Atmosphere Packaging (MAP) extends meat shelf life by optimizing headspace gas composition, typically using high CO2 and low O2 levels to inhibit microbial growth while preserving color and freshness. Vacuum packaging removes oxygen entirely, limiting aerobic spoilage but may cause anaerobic conditions that alter meat texture and flavor due to changes in headspace gas profiles.

Vacuum Packaging-Induced Cold Shortening

Vacuum packaging extends meat shelf life by reducing oxygen exposure but can induce cold shortening due to rapid chilling without oxygen, causing tougher texture and compromised tenderness; controlling chilling rates and post-mortem aging helps mitigate vacuum packaging-induced cold shortening in meat products. Effective cold chain management and optimized vacuum packaging conditions are critical to preserving meat quality while maximizing shelf life.

MAP packaging vs vacuum packaging for meat shelf life Infographic

agridif.com

agridif.com